Showing Spotlights 113 - 120 of 624 in category All (newest first):

Biofabrication is a revolutionizing toolkit for regenerative medicine that allows cells and other biomaterials to be precisely combined and patterned into three-dimensional (3D) constructs through automated, cell-friendly fabrication methods. With rapid advanced in 3D-printing hardware on one hand and bioink materials on the other, biofabrication techniques have gained significant momentum and provide a powerful approach to tackle major hurdles in the generation of engineered living tissues. While 3D bioprinting is still in its early stages, the remarkable leap it has made in recent years points to the eventual reality of lab-grown, functional organs.

Biofabrication is a revolutionizing toolkit for regenerative medicine that allows cells and other biomaterials to be precisely combined and patterned into three-dimensional (3D) constructs through automated, cell-friendly fabrication methods. With rapid advanced in 3D-printing hardware on one hand and bioink materials on the other, biofabrication techniques have gained significant momentum and provide a powerful approach to tackle major hurdles in the generation of engineered living tissues. While 3D bioprinting is still in its early stages, the remarkable leap it has made in recent years points to the eventual reality of lab-grown, functional organs.

Mar 25th, 2020

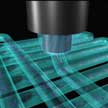

Researchers have developed a method to produce a wood-derived, fully bio-based, and environmentally friendly flexible electronic circuit. They tailored the wood nanostructure to create a wood film with high transparency, flexibility, and strong mechanical properties. This material compares favorably with previously published two-dimensional cellulose-based materials developed for electronics or structural applications. This flexible circuit highlights the fact that wood can be used as a feedstock, with the potential to displace petroleum-based material for high-value products.

Researchers have developed a method to produce a wood-derived, fully bio-based, and environmentally friendly flexible electronic circuit. They tailored the wood nanostructure to create a wood film with high transparency, flexibility, and strong mechanical properties. This material compares favorably with previously published two-dimensional cellulose-based materials developed for electronics or structural applications. This flexible circuit highlights the fact that wood can be used as a feedstock, with the potential to displace petroleum-based material for high-value products.

Mar 12th, 2020

Organic-inorganic metal halide perovskites have emerged as a promising optoelectronic material with exceptional structure and property tunability. This new generation of functional materials possess excellent properties such as large optical absorption, long carrier diffusion length, high carrier mobility, and low-cost solution production process. Fabrication methods based on inkjet printing emerged for patterning such perovskite micro- and nanostructures. However, these patterning techniques for perovskites are still limited to in-plane fabrication and alignment. To overcome this limitation, researchers have developed a method to print perovskite nanostructures in three dimensions.

Organic-inorganic metal halide perovskites have emerged as a promising optoelectronic material with exceptional structure and property tunability. This new generation of functional materials possess excellent properties such as large optical absorption, long carrier diffusion length, high carrier mobility, and low-cost solution production process. Fabrication methods based on inkjet printing emerged for patterning such perovskite micro- and nanostructures. However, these patterning techniques for perovskites are still limited to in-plane fabrication and alignment. To overcome this limitation, researchers have developed a method to print perovskite nanostructures in three dimensions.

Feb 11th, 2020

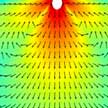

Plasmonic 'nanotweezers' are structures made of noble metals that concentrate and absorb light, resulting in 'plasmonic hotspots' that make it possible to manipulate nanoscale objects suspended in a fluid. Trapping or sensing of nanoparticles using nanotweezers suffers from an intrinsic problem of low throughput as the particle delivery process is often diffusion-limited. Researhers have developed bubble- and convection-assisted trapping techniques that overcome the diffusion-limited trapping in nanoaperture tweezers and enable a reduction of 1-2 orders of magnitude in particle-trapping time compared to that of a diffusion-limited trap.

Plasmonic 'nanotweezers' are structures made of noble metals that concentrate and absorb light, resulting in 'plasmonic hotspots' that make it possible to manipulate nanoscale objects suspended in a fluid. Trapping or sensing of nanoparticles using nanotweezers suffers from an intrinsic problem of low throughput as the particle delivery process is often diffusion-limited. Researhers have developed bubble- and convection-assisted trapping techniques that overcome the diffusion-limited trapping in nanoaperture tweezers and enable a reduction of 1-2 orders of magnitude in particle-trapping time compared to that of a diffusion-limited trap.

Dec 23rd, 2019

Researchers have developed a facile and versatile strategy to directly print hydrogels into biomimetic soft robots. Hydrogel materials possess intrinsic softness and they also exhibit other favorable properties that make them a perfect fabrication material for biomimetic soft robots: stretchability, biocompatibility, permeability, and stimuli-adaptability. The team harnesses biocompatible alginate as a rheological modifier to manufacture 3D freeform architectures of both chemically and physically cross-linked hydrogels using the direct-inkwrite printing.

Researchers have developed a facile and versatile strategy to directly print hydrogels into biomimetic soft robots. Hydrogel materials possess intrinsic softness and they also exhibit other favorable properties that make them a perfect fabrication material for biomimetic soft robots: stretchability, biocompatibility, permeability, and stimuli-adaptability. The team harnesses biocompatible alginate as a rheological modifier to manufacture 3D freeform architectures of both chemically and physically cross-linked hydrogels using the direct-inkwrite printing.

Dec 18th, 2019

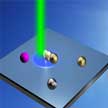

Researchers show that by introducing a surfactant layer to modify the particle-substrate interactions, a variety of colloidal particles can be manipulated in a non-invasive and contactless way through coordinating optical heating and scattering forces. This novel technique provides a versatile and powerful platform to manipulate and reconfigurably assemble colloidal particles on solid substrates, without the need to involve fluidic environments. This technique represents a milestone in pushing the working conditions of optical tweezers from fluidic to solid phases, which is capable of versatile manipulation and dynamic assembly of colloidal nanostructures on solid substrates directly.

Researchers show that by introducing a surfactant layer to modify the particle-substrate interactions, a variety of colloidal particles can be manipulated in a non-invasive and contactless way through coordinating optical heating and scattering forces. This novel technique provides a versatile and powerful platform to manipulate and reconfigurably assemble colloidal particles on solid substrates, without the need to involve fluidic environments. This technique represents a milestone in pushing the working conditions of optical tweezers from fluidic to solid phases, which is capable of versatile manipulation and dynamic assembly of colloidal nanostructures on solid substrates directly.

Dec 13th, 2019

Researchers have identified kirigami as an intriguing tool to create programmable mechanical metamaterials with unconventional mechanical and morphological responses. These reconfigurable metamaterials offer a new material platform to achieve dramatic changes of mechanical and optical properties, which are arising from dynamically tunable geometrical structures. A key feature of kirigami metamaterials is that they are conveniently cut when flat and then exploit local elastic instabilities to transform into complex 3D configurations upon stretching.

Researchers have identified kirigami as an intriguing tool to create programmable mechanical metamaterials with unconventional mechanical and morphological responses. These reconfigurable metamaterials offer a new material platform to achieve dramatic changes of mechanical and optical properties, which are arising from dynamically tunable geometrical structures. A key feature of kirigami metamaterials is that they are conveniently cut when flat and then exploit local elastic instabilities to transform into complex 3D configurations upon stretching.

Dec 12th, 2019

Researchers have demonstrated the first large-scale flexible thermal flow sensor array on a thin-film. This flow sensor - based on a calorimetric sensing mechanism - can not only monitor flow intensity but also flow direction. More importantly, these sensors can be attached onto curved surfaces for real-time flow monitoring. Flow separation is a common phenomenon affecting aircraft, wind turbine blades, micro aerials, and underwater vehicles. Owing to its unsteady flow profile, such separation is usually undesirable because either the airfoil efficiency decreases or large pressure fluctuations emerge. Consequently, precise monitoring is crucial to reduce or even prevent the flow separation effect.

Researchers have demonstrated the first large-scale flexible thermal flow sensor array on a thin-film. This flow sensor - based on a calorimetric sensing mechanism - can not only monitor flow intensity but also flow direction. More importantly, these sensors can be attached onto curved surfaces for real-time flow monitoring. Flow separation is a common phenomenon affecting aircraft, wind turbine blades, micro aerials, and underwater vehicles. Owing to its unsteady flow profile, such separation is usually undesirable because either the airfoil efficiency decreases or large pressure fluctuations emerge. Consequently, precise monitoring is crucial to reduce or even prevent the flow separation effect.

Nov 26th, 2019

Biofabrication is a revolutionizing toolkit for regenerative medicine that allows cells and other biomaterials to be precisely combined and patterned into three-dimensional (3D) constructs through automated, cell-friendly fabrication methods. With rapid advanced in 3D-printing hardware on one hand and bioink materials on the other, biofabrication techniques have gained significant momentum and provide a powerful approach to tackle major hurdles in the generation of engineered living tissues. While 3D bioprinting is still in its early stages, the remarkable leap it has made in recent years points to the eventual reality of lab-grown, functional organs.

Biofabrication is a revolutionizing toolkit for regenerative medicine that allows cells and other biomaterials to be precisely combined and patterned into three-dimensional (3D) constructs through automated, cell-friendly fabrication methods. With rapid advanced in 3D-printing hardware on one hand and bioink materials on the other, biofabrication techniques have gained significant momentum and provide a powerful approach to tackle major hurdles in the generation of engineered living tissues. While 3D bioprinting is still in its early stages, the remarkable leap it has made in recent years points to the eventual reality of lab-grown, functional organs.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed