Showing Spotlights 1241 - 1248 of 2784 in category All (newest first):

Previous work in stretchable, flexible electronics has shown that conventional, silicon wafer based fabrication techniques can be modified to apply electronics conformally to the heterogeneous topography of the skin. Now, researchers have demonstrated the development of a device platform that enables high precision temperature mapping of the skin in ways that have, until now, been extremely difficult in research and impossible to implement for widespread use.

Previous work in stretchable, flexible electronics has shown that conventional, silicon wafer based fabrication techniques can be modified to apply electronics conformally to the heterogeneous topography of the skin. Now, researchers have demonstrated the development of a device platform that enables high precision temperature mapping of the skin in ways that have, until now, been extremely difficult in research and impossible to implement for widespread use.

Dec 9th, 2013

The quest for efficient low-cost solutions for solar energy conversion faces many obstacles, both, fundamental and technical. As a result, even 'ideal' solar cells have maximum intrinsic efficiency - known as the Shockley-Queisser (S-Q) limit - of 33% for the illumination by the non-concentrated sunlight. A number of architectures have been proposed for reducing losses in solar cells in order to overcome the S-Q single-junction limit. Now, researchers have proposed a new way to break the fundamental S-Q limit by using a mechanism of thermal up-conversion.

The quest for efficient low-cost solutions for solar energy conversion faces many obstacles, both, fundamental and technical. As a result, even 'ideal' solar cells have maximum intrinsic efficiency - known as the Shockley-Queisser (S-Q) limit - of 33% for the illumination by the non-concentrated sunlight. A number of architectures have been proposed for reducing losses in solar cells in order to overcome the S-Q single-junction limit. Now, researchers have proposed a new way to break the fundamental S-Q limit by using a mechanism of thermal up-conversion.

Dec 5th, 2013

As researchers continue to develop the use of graphene in energy storage devices, other two-dimensional (2D) inorganic materials like 2D transition metal disulfides have attracted extensive scientific attention. Vanadium disulfide few-layered nanosheets have been recently achieved experimentally, and in new work, scientists systematically investigated the adsorption and diffusion of lithium on the recently synthesized vanadium disulfide monolayer in comparison with MoS2 monolayer and graphite.

As researchers continue to develop the use of graphene in energy storage devices, other two-dimensional (2D) inorganic materials like 2D transition metal disulfides have attracted extensive scientific attention. Vanadium disulfide few-layered nanosheets have been recently achieved experimentally, and in new work, scientists systematically investigated the adsorption and diffusion of lithium on the recently synthesized vanadium disulfide monolayer in comparison with MoS2 monolayer and graphite.

Dec 3rd, 2013

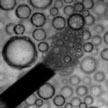

The construction of artificial micro- and nanomotors is a high priority in the nanotechnology field owing to their great potential for diverse potential applications, ranging from targeted drug delivery, on-chip diagnostics and biosensing, or pumping of fluids at the microscale to environmental remediation. In new work, researchers have now reported the first example of micromotors for the active degradation of organic pollutants in solution. The novelty of this work lies in the synergy between internal and external functionality of the micromotors.

The construction of artificial micro- and nanomotors is a high priority in the nanotechnology field owing to their great potential for diverse potential applications, ranging from targeted drug delivery, on-chip diagnostics and biosensing, or pumping of fluids at the microscale to environmental remediation. In new work, researchers have now reported the first example of micromotors for the active degradation of organic pollutants in solution. The novelty of this work lies in the synergy between internal and external functionality of the micromotors.

Dec 2nd, 2013

Functionalized graphene holds exceptional promise for biological and chemical sensors. In new work, researchers have shown that the distinctive 2D structure of graphene oxide, combined with its superpermeability to water molecules, leads to sensing devices with an unprecedented speed. The team reports the experimental observation of the unparalleled response speed of humidity sensors based on graphene oxide, which are - to the best of the scientists' knowledge - the fastest humidity sensors ever reported.

Functionalized graphene holds exceptional promise for biological and chemical sensors. In new work, researchers have shown that the distinctive 2D structure of graphene oxide, combined with its superpermeability to water molecules, leads to sensing devices with an unprecedented speed. The team reports the experimental observation of the unparalleled response speed of humidity sensors based on graphene oxide, which are - to the best of the scientists' knowledge - the fastest humidity sensors ever reported.

Nov 27th, 2013

Over the past decade, electromagnetic metamaterials have become an extremely active field of research in both the physics and the engineering communities. Metamaterials gain their properties from their structure rather than directly from their composition and show the peculiarity of having an index of refraction at optical frequencies from negative to very high positive values. Researchers have now suggested a new type of optical sensing device based on artificial metamaterials with topological darkness.

Over the past decade, electromagnetic metamaterials have become an extremely active field of research in both the physics and the engineering communities. Metamaterials gain their properties from their structure rather than directly from their composition and show the peculiarity of having an index of refraction at optical frequencies from negative to very high positive values. Researchers have now suggested a new type of optical sensing device based on artificial metamaterials with topological darkness.

Nov 26th, 2013

There is an almost infinite number of mechanical energy sources all around us - basically, anything that moves can be harvested for energy. These environmental energy sources can the very large, like wave power in the oceans, or very small, like rain drops or biomechanical energy from heart beat, breathing, and blood flow. With the increasing use of nanotechnology materials and applications in energy research, scientists are finding more and more ways to tap into these pretty much limitless sources of energy. Self-powered nanotechnology based on piezoelectric nanogenerators aims at powering nanodevices and nanosystems using the energy harvested from the environment in which these systems are suppose to operate.

There is an almost infinite number of mechanical energy sources all around us - basically, anything that moves can be harvested for energy. These environmental energy sources can the very large, like wave power in the oceans, or very small, like rain drops or biomechanical energy from heart beat, breathing, and blood flow. With the increasing use of nanotechnology materials and applications in energy research, scientists are finding more and more ways to tap into these pretty much limitless sources of energy. Self-powered nanotechnology based on piezoelectric nanogenerators aims at powering nanodevices and nanosystems using the energy harvested from the environment in which these systems are suppose to operate.

Nov 19th, 2013

Advances in materials, fabrication strategies and device designs for flexible and stretchable electronics and sensors make it possible to envision a not-too-distant future where ultra-thin, flexible circuits based on inorganic semiconductors can be wrapped and attached to any imaginable surface, including body parts and even internal organs. Robotic technologies will also benefit as it becomes possible to fabricate electronic skin ('e-skin') that, for instance, could allow surgical robots to interact, in a soft contacting mode, with their surroundings through touch.

Advances in materials, fabrication strategies and device designs for flexible and stretchable electronics and sensors make it possible to envision a not-too-distant future where ultra-thin, flexible circuits based on inorganic semiconductors can be wrapped and attached to any imaginable surface, including body parts and even internal organs. Robotic technologies will also benefit as it becomes possible to fabricate electronic skin ('e-skin') that, for instance, could allow surgical robots to interact, in a soft contacting mode, with their surroundings through touch.

Nov 15th, 2013

Previous work in stretchable, flexible electronics has shown that conventional, silicon wafer based fabrication techniques can be modified to apply electronics conformally to the heterogeneous topography of the skin. Now, researchers have demonstrated the development of a device platform that enables high precision temperature mapping of the skin in ways that have, until now, been extremely difficult in research and impossible to implement for widespread use.

Previous work in stretchable, flexible electronics has shown that conventional, silicon wafer based fabrication techniques can be modified to apply electronics conformally to the heterogeneous topography of the skin. Now, researchers have demonstrated the development of a device platform that enables high precision temperature mapping of the skin in ways that have, until now, been extremely difficult in research and impossible to implement for widespread use.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed