Showing Spotlights 1433 - 1440 of 2783 in category All (newest first):

Multiphoton lithography (MPL) is a microfabrication technique used to create three-dimensional microscale objects with complex geometrical arrangements. Of the various chemistries used to produce solid forms in MPL, protein photocrosslinking has been of particular value in biological applications. In new work, researchers have now described a strategy for creating a nearly unlimited range of microforms from crosslinked protein, including structures composed of multiple proteins. They also describe MPL microfabrication of complex unconstrained objects using high-viscosity protein-based reagents. To avoid drift during fabrication of microforms that are not in integral contact with a surface, the team developed a methodology for producing high-viscosity protein-based reagents, or "protogels". These materials allow the fabrication of protein-based objects that retain rotational and translational degrees of freedom.

Multiphoton lithography (MPL) is a microfabrication technique used to create three-dimensional microscale objects with complex geometrical arrangements. Of the various chemistries used to produce solid forms in MPL, protein photocrosslinking has been of particular value in biological applications. In new work, researchers have now described a strategy for creating a nearly unlimited range of microforms from crosslinked protein, including structures composed of multiple proteins. They also describe MPL microfabrication of complex unconstrained objects using high-viscosity protein-based reagents. To avoid drift during fabrication of microforms that are not in integral contact with a surface, the team developed a methodology for producing high-viscosity protein-based reagents, or "protogels". These materials allow the fabrication of protein-based objects that retain rotational and translational degrees of freedom.

Sep 6th, 2012

Lithography based on block copolymer self-assembly has received significant attention due to the ability to achieve morphologies with dimensions in the range of 10 to 20 nm or even below. Block copolymer lithography is a cost-effective, parallel, and scalable nanolithography for densely packed periodic arrays of nanoscale features, whose typical dimension scale is beyond the resolution limit of conventional photolithography. Researchers have now introduced a conceptually new and versatile strategy to achieve asymmetric line patterns. This is the first work to demonstrate that highly asymmetric line nanopatterning is possible even though a block copolymer self-assembly technique is used.

Lithography based on block copolymer self-assembly has received significant attention due to the ability to achieve morphologies with dimensions in the range of 10 to 20 nm or even below. Block copolymer lithography is a cost-effective, parallel, and scalable nanolithography for densely packed periodic arrays of nanoscale features, whose typical dimension scale is beyond the resolution limit of conventional photolithography. Researchers have now introduced a conceptually new and versatile strategy to achieve asymmetric line patterns. This is the first work to demonstrate that highly asymmetric line nanopatterning is possible even though a block copolymer self-assembly technique is used.

Sep 5th, 2012

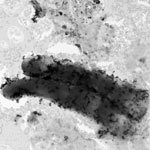

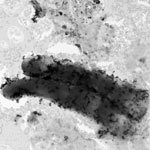

Researchers have shown that it is possible to use graphene sheets to create a superhydrophobic coating material that shows stable superhydrophobicity under both static as well as dynamic (droplet impact) conditions. They demonstrates a novel macroscopic graphene structure composed of an integrated foam-like network of graphene sheets with well-controlled microscale porosity and roughness. The novel idea here was to grow graphene over a sacrificial nickel foam template and then leech away the nickel, leaving behind a graphene foam with few-layered graphene sheets that comprise the walls of the foam. The foam is then coated with a 200nm layer of Teflon.

Researchers have shown that it is possible to use graphene sheets to create a superhydrophobic coating material that shows stable superhydrophobicity under both static as well as dynamic (droplet impact) conditions. They demonstrates a novel macroscopic graphene structure composed of an integrated foam-like network of graphene sheets with well-controlled microscale porosity and roughness. The novel idea here was to grow graphene over a sacrificial nickel foam template and then leech away the nickel, leaving behind a graphene foam with few-layered graphene sheets that comprise the walls of the foam. The foam is then coated with a 200nm layer of Teflon.

Sep 4th, 2012

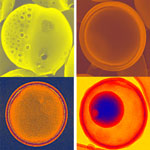

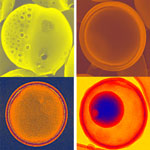

Ultrasonic spray pyrolysis (USP) has been widely used in industry for spherical solid powder production, particularly of metal oxides. For some applications, though, porous particles are more desirable than dense ones. Back in 2005, researchers developed a technique to synthesize porous micro- and nanoparticles via USP. This method has since been expanded to prepare porous carbon microspheres. The high surface area and unique porous structures suggest that porous carbon spheres can be useful for electrode materials, adsorbents, and catalyst supports. Researchers at the University of Illinois already demonstrated the use of carbon microspheres as supercapacitors. Now, the team has expanded the aerosol synthesis of porous carbon materials by the use of energetic carbon precursors. Some of the resulting porous carbon spheres exhibit unique and unprecedented morphologies.

Ultrasonic spray pyrolysis (USP) has been widely used in industry for spherical solid powder production, particularly of metal oxides. For some applications, though, porous particles are more desirable than dense ones. Back in 2005, researchers developed a technique to synthesize porous micro- and nanoparticles via USP. This method has since been expanded to prepare porous carbon microspheres. The high surface area and unique porous structures suggest that porous carbon spheres can be useful for electrode materials, adsorbents, and catalyst supports. Researchers at the University of Illinois already demonstrated the use of carbon microspheres as supercapacitors. Now, the team has expanded the aerosol synthesis of porous carbon materials by the use of energetic carbon precursors. Some of the resulting porous carbon spheres exhibit unique and unprecedented morphologies.

Sep 3rd, 2012

Aquatic ecotoxicity test methods, which are routinely applied to testing of nanomaterials, were originally developed for water soluble chemicals. Nanomaterials are fundamentally different from many 'conventional' chemicals as they often have limited or no solubility at all and are potentially released to the environment in a particulate form (e.g. carbon nanotubes). Only limited nano-specific guidance on ecotoxicity testing is currently available, for instance existing OECD ecotoxicity test guidelines to nanomaterials. These guidelines exhibit a number of specific shortcomings mainly related to characterization, exposure preparation, quantification and monitoring concentrations, and dose-metrics. A new paper from scientists in Denmark contributes to the progress in algae testing of nanomaterials. This work also aids in the development of additional guidance as it adds to the understanding of pros and cons of different techniques for biomass quantification.

Aquatic ecotoxicity test methods, which are routinely applied to testing of nanomaterials, were originally developed for water soluble chemicals. Nanomaterials are fundamentally different from many 'conventional' chemicals as they often have limited or no solubility at all and are potentially released to the environment in a particulate form (e.g. carbon nanotubes). Only limited nano-specific guidance on ecotoxicity testing is currently available, for instance existing OECD ecotoxicity test guidelines to nanomaterials. These guidelines exhibit a number of specific shortcomings mainly related to characterization, exposure preparation, quantification and monitoring concentrations, and dose-metrics. A new paper from scientists in Denmark contributes to the progress in algae testing of nanomaterials. This work also aids in the development of additional guidance as it adds to the understanding of pros and cons of different techniques for biomass quantification.

Aug 31st, 2012

Buildings and other man-made structures consume as much as 30-40% of the primary energy in the world, mainly for heating, cooling, ventilation, and lighting. 'Smart' windows are expected to play a significant role in reducing the energy consumption of homes in two ways: by generating energy themselves; and by providing better insulation by allowing light in and keeping the heat out (in hot summers) or in (in cold winters). Vanadium dioxide (VO2) has long been recognized as a a material of significant technological interest for optics and electronics and a promising candidate for making 'smart' windows: it can transition from a transparent semiconductive state at low temperatures, allowing infrared radiation through, to an opaque metallic state at high temperatures, while still allowing visible light to get through. In new work, researchers have now offered a simple method for promoting the production of monoclinic VO2 nanoparticles by doping.

Buildings and other man-made structures consume as much as 30-40% of the primary energy in the world, mainly for heating, cooling, ventilation, and lighting. 'Smart' windows are expected to play a significant role in reducing the energy consumption of homes in two ways: by generating energy themselves; and by providing better insulation by allowing light in and keeping the heat out (in hot summers) or in (in cold winters). Vanadium dioxide (VO2) has long been recognized as a a material of significant technological interest for optics and electronics and a promising candidate for making 'smart' windows: it can transition from a transparent semiconductive state at low temperatures, allowing infrared radiation through, to an opaque metallic state at high temperatures, while still allowing visible light to get through. In new work, researchers have now offered a simple method for promoting the production of monoclinic VO2 nanoparticles by doping.

Aug 27th, 2012

Micro- and nanoporous materials can widely be found in nature, be it zeolite minerals, cell membranes, or diatom skeletons. Researchers are developing artificial analogues of such materials, i.e. nanoporous materials, for industrial applications in areas such as catalysis, water purification, environmental clean-up, molecular separation and proton exchange membranes for fuel cells. Manufacturing nanosieves with straight nanopores is still challenging, especially when the pore size is less than 10 nm. Researchers in Korea have now developed a novel material and fabrication technique that allows easy fabrication of nanosieves with sub-10 nm nanopores with straight pore-structure. With it, controlling the pore size from sub-nm to 5 nm becomes very easy.

Micro- and nanoporous materials can widely be found in nature, be it zeolite minerals, cell membranes, or diatom skeletons. Researchers are developing artificial analogues of such materials, i.e. nanoporous materials, for industrial applications in areas such as catalysis, water purification, environmental clean-up, molecular separation and proton exchange membranes for fuel cells. Manufacturing nanosieves with straight nanopores is still challenging, especially when the pore size is less than 10 nm. Researchers in Korea have now developed a novel material and fabrication technique that allows easy fabrication of nanosieves with sub-10 nm nanopores with straight pore-structure. With it, controlling the pore size from sub-nm to 5 nm becomes very easy.

Aug 24th, 2012

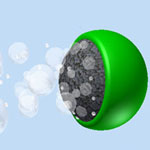

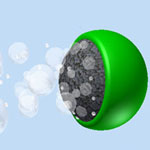

Man-made micro- and nanoscale motors have received a tremendous recent interest owing to their great potential for diverse potential applications, ranging from targeted drug delivery, microchip diagnostics or environmental remediation. Particular attention has been given to self-propelled chemically-powered micro/nanoscale motors, such as catalytic nanowires, microtube engines, or spherical Janus microparticles. Although significant progress over the past 10 years has greatly advanced the capabilities of these tiny man-made machines, such catalytic motors have predominantly relied on an external hydrogen peroxide fuel that impedes many practical applications. Researchers have now demonstrated the first example of a water-driven bubble-propelled micromotor that eliminates the requirement for the common hydrogen peroxide fuel.

Man-made micro- and nanoscale motors have received a tremendous recent interest owing to their great potential for diverse potential applications, ranging from targeted drug delivery, microchip diagnostics or environmental remediation. Particular attention has been given to self-propelled chemically-powered micro/nanoscale motors, such as catalytic nanowires, microtube engines, or spherical Janus microparticles. Although significant progress over the past 10 years has greatly advanced the capabilities of these tiny man-made machines, such catalytic motors have predominantly relied on an external hydrogen peroxide fuel that impedes many practical applications. Researchers have now demonstrated the first example of a water-driven bubble-propelled micromotor that eliminates the requirement for the common hydrogen peroxide fuel.

Aug 23rd, 2012

Multiphoton lithography (MPL) is a microfabrication technique used to create three-dimensional microscale objects with complex geometrical arrangements. Of the various chemistries used to produce solid forms in MPL, protein photocrosslinking has been of particular value in biological applications. In new work, researchers have now described a strategy for creating a nearly unlimited range of microforms from crosslinked protein, including structures composed of multiple proteins. They also describe MPL microfabrication of complex unconstrained objects using high-viscosity protein-based reagents. To avoid drift during fabrication of microforms that are not in integral contact with a surface, the team developed a methodology for producing high-viscosity protein-based reagents, or "protogels". These materials allow the fabrication of protein-based objects that retain rotational and translational degrees of freedom.

Multiphoton lithography (MPL) is a microfabrication technique used to create three-dimensional microscale objects with complex geometrical arrangements. Of the various chemistries used to produce solid forms in MPL, protein photocrosslinking has been of particular value in biological applications. In new work, researchers have now described a strategy for creating a nearly unlimited range of microforms from crosslinked protein, including structures composed of multiple proteins. They also describe MPL microfabrication of complex unconstrained objects using high-viscosity protein-based reagents. To avoid drift during fabrication of microforms that are not in integral contact with a surface, the team developed a methodology for producing high-viscosity protein-based reagents, or "protogels". These materials allow the fabrication of protein-based objects that retain rotational and translational degrees of freedom.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed