Showing Spotlights 193 - 200 of 624 in category All (newest first):

Paper, probably the cheapest and most widely used flexible and eco-friendly material in daily life, is a promising substrate for making flexible devices ranging from electronics to microfluidics, energy storage and sensors. In new work, researchers have developed a new and reliable method to achieve conformal coating of individual cellulose fibers in the paper and the fabrication of a metal electrode via patterning of gold and silver layers on the coated paper.

Paper, probably the cheapest and most widely used flexible and eco-friendly material in daily life, is a promising substrate for making flexible devices ranging from electronics to microfluidics, energy storage and sensors. In new work, researchers have developed a new and reliable method to achieve conformal coating of individual cellulose fibers in the paper and the fabrication of a metal electrode via patterning of gold and silver layers on the coated paper.

Jan 10th, 2017

Lanthanide dopants play an important role in desirable phase transformations of aluminum oxide (alumina) in order to achieve optimized physical and chemical properties. For example, the presence of dopants strengthens the grain boundaries of alumina, largely affecting its mechanical properties. New research indicates that there are significant structural changes to the lattice with addition of the dopant, and that understanding these effects will lead to future research for addressing these challenges.

Lanthanide dopants play an important role in desirable phase transformations of aluminum oxide (alumina) in order to achieve optimized physical and chemical properties. For example, the presence of dopants strengthens the grain boundaries of alumina, largely affecting its mechanical properties. New research indicates that there are significant structural changes to the lattice with addition of the dopant, and that understanding these effects will lead to future research for addressing these challenges.

Jan 9th, 2017

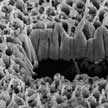

Maximizing light absorption of nanomaterials has been an emerging research field in the recent years due to its attractiveness in a wide range of applications that involves conversion or utilization of solar energy. However, most of the concepts reported are based on multi-layered architecture inspired by optical impedance matching concepts that requires complicated non-scalable fabrication process such as electron beam lithography. Efforts on maximizing light absorption via nanostructuring remain scarce. Researchers have now reported such a material - a nanolayer of black gold.

Maximizing light absorption of nanomaterials has been an emerging research field in the recent years due to its attractiveness in a wide range of applications that involves conversion or utilization of solar energy. However, most of the concepts reported are based on multi-layered architecture inspired by optical impedance matching concepts that requires complicated non-scalable fabrication process such as electron beam lithography. Efforts on maximizing light absorption via nanostructuring remain scarce. Researchers have now reported such a material - a nanolayer of black gold.

Dec 21st, 2016

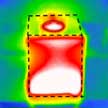

With the exponential rise of power dissipation in electric devices such as integrated circuits or micro/nano electro mechanical systems (MEMS/NEMS), new thermal management solutions are in high demand. Thermal switches, being devices capable of controlling the temperature flow between two surfaces, are one of the solutions capable of effectively tackling this problem. In new work, researchers demonstrate an innovative magnetically actuated thermal switch based on nanofluids capable of controlling both the magnitude and direction of the heat flux. This device takes advantage of the thermal conductivity increase in magnetic nanofluids when submitted to an applied magnetic field parallel to the temperature gradient.

With the exponential rise of power dissipation in electric devices such as integrated circuits or micro/nano electro mechanical systems (MEMS/NEMS), new thermal management solutions are in high demand. Thermal switches, being devices capable of controlling the temperature flow between two surfaces, are one of the solutions capable of effectively tackling this problem. In new work, researchers demonstrate an innovative magnetically actuated thermal switch based on nanofluids capable of controlling both the magnitude and direction of the heat flux. This device takes advantage of the thermal conductivity increase in magnetic nanofluids when submitted to an applied magnetic field parallel to the temperature gradient.

Dec 9th, 2016

Following up on previous theoretical predictions, researchers now have demonstrated two high-yield methods for fabricating antimonenes - wide-band-gap semiconductors that under strain become direct band-gap semiconductors. Such dramatic transitions of electronic properties could open a new door for nanoscale transistors with high on/off ratio, blue/UV optoelectronic devices, and nanomechanical sensors based on new ultrathin semiconductors. The new approach is generic for various transparent conducting oxides as well as other oxide nanocrystal inks.

Following up on previous theoretical predictions, researchers now have demonstrated two high-yield methods for fabricating antimonenes - wide-band-gap semiconductors that under strain become direct band-gap semiconductors. Such dramatic transitions of electronic properties could open a new door for nanoscale transistors with high on/off ratio, blue/UV optoelectronic devices, and nanomechanical sensors based on new ultrathin semiconductors. The new approach is generic for various transparent conducting oxides as well as other oxide nanocrystal inks.

Dec 5th, 2016

Oxygen evolution reaction (OER) is the core process - but also the bottleneck - in many energy devices such as metal-air batteries and water-splitting techniques, calling for new insights in rational design of OER electrocatalysts. The perovskite family exhibits superb OER reactivity, but its poor conductivity remains a big problem, not to mention that the morphology of perovskite oxides is hard to control. In situ hybridization of perovskite oxides with conductive frameworks is an efficient strategy to solve these problems, as researchers report in new work.

Oxygen evolution reaction (OER) is the core process - but also the bottleneck - in many energy devices such as metal-air batteries and water-splitting techniques, calling for new insights in rational design of OER electrocatalysts. The perovskite family exhibits superb OER reactivity, but its poor conductivity remains a big problem, not to mention that the morphology of perovskite oxides is hard to control. In situ hybridization of perovskite oxides with conductive frameworks is an efficient strategy to solve these problems, as researchers report in new work.

Oct 24th, 2016

Jellyfish can change from a transparent state to an opaque state when disturbed. Tactile stimulation can instantaneously evoke the contraction of radial muscles in the margin of a nectosac, resulting in a crumpled morphology with inward folds. Due to the wrinkles/folding that form, light will be scattered instead of travelling directly through the skin, resulting in a more opaque appearance. Inspired by marine life, a variety of these mechanochromic devices are created by researchers. These devices are able to undergo change from transparency to opaqueness, as well as a changes in color and pattern upon simply stretching and releasing the substrate.

Jellyfish can change from a transparent state to an opaque state when disturbed. Tactile stimulation can instantaneously evoke the contraction of radial muscles in the margin of a nectosac, resulting in a crumpled morphology with inward folds. Due to the wrinkles/folding that form, light will be scattered instead of travelling directly through the skin, resulting in a more opaque appearance. Inspired by marine life, a variety of these mechanochromic devices are created by researchers. These devices are able to undergo change from transparency to opaqueness, as well as a changes in color and pattern upon simply stretching and releasing the substrate.

Sep 2nd, 2016

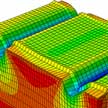

Whether it is possible to achieve high formability in quasicrystals and how quasicrystals are plastically deformed at room temperature have been long-standing questions since their discovery. In new work, an international group of researchers has found that a typically brittle quasicrystal exhibits superior ductility (ductility is a solid material's ability to deform under stress without fracture) at the sub-micrometer scales and at room temperature. Furthermore, their experiments indicate that 'dislocation glide' could be the dominating deformation mechanism for quasicrystals under high-stress and low temperature conditions, which has been not poorly understood before.

Whether it is possible to achieve high formability in quasicrystals and how quasicrystals are plastically deformed at room temperature have been long-standing questions since their discovery. In new work, an international group of researchers has found that a typically brittle quasicrystal exhibits superior ductility (ductility is a solid material's ability to deform under stress without fracture) at the sub-micrometer scales and at room temperature. Furthermore, their experiments indicate that 'dislocation glide' could be the dominating deformation mechanism for quasicrystals under high-stress and low temperature conditions, which has been not poorly understood before.

Aug 12th, 2016

Paper, probably the cheapest and most widely used flexible and eco-friendly material in daily life, is a promising substrate for making flexible devices ranging from electronics to microfluidics, energy storage and sensors. In new work, researchers have developed a new and reliable method to achieve conformal coating of individual cellulose fibers in the paper and the fabrication of a metal electrode via patterning of gold and silver layers on the coated paper.

Paper, probably the cheapest and most widely used flexible and eco-friendly material in daily life, is a promising substrate for making flexible devices ranging from electronics to microfluidics, energy storage and sensors. In new work, researchers have developed a new and reliable method to achieve conformal coating of individual cellulose fibers in the paper and the fabrication of a metal electrode via patterning of gold and silver layers on the coated paper.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed