Showing Spotlights 289 - 296 of 624 in category All (newest first):

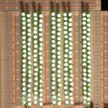

With all the rapid progress going on in research and commercialization of flexible and transparent electronics, the obvious question is not if, but when it will be possible to build a flexible and transparent truly high performance computer. A research team has now shown, for the first time, a generic batch fabrication process to obtain mechanically flexible and transparent mono-crystalline silicon (100) from bulk wafers. The researchers demonstrate a pragmatic pathway for a truly high performance computation systems on flexible and transparent platform.

With all the rapid progress going on in research and commercialization of flexible and transparent electronics, the obvious question is not if, but when it will be possible to build a flexible and transparent truly high performance computer. A research team has now shown, for the first time, a generic batch fabrication process to obtain mechanically flexible and transparent mono-crystalline silicon (100) from bulk wafers. The researchers demonstrate a pragmatic pathway for a truly high performance computation systems on flexible and transparent platform.

Mar 1st, 2013

Harvesting unexploited energy in the living environment is increasingly becoming an intense research area as the global push to replace fossil fuels with clean and renewable energy sources heats up. There is an almost infinite number of mechanical energy sources all around us - basically, anything that moves can be harvested for energy. This ranges from the very large, like wave power in the oceans, to the very small like rain drops or biomechanical energy from heart beat, breathing, and blood flow. In an intriguing demonstration, researchers at Georgia Tech have now demonstrated that the technology offered by nanogenerators can also be used for large-scale energy harvesting.

Harvesting unexploited energy in the living environment is increasingly becoming an intense research area as the global push to replace fossil fuels with clean and renewable energy sources heats up. There is an almost infinite number of mechanical energy sources all around us - basically, anything that moves can be harvested for energy. This ranges from the very large, like wave power in the oceans, to the very small like rain drops or biomechanical energy from heart beat, breathing, and blood flow. In an intriguing demonstration, researchers at Georgia Tech have now demonstrated that the technology offered by nanogenerators can also be used for large-scale energy harvesting.

Feb 28th, 2013

DNA is a powerful biomaterial for creating rationally designed and functionally enhanced nanostructures. Emerging DNA nanotechnology employs DNA as a programmable building material for self-assembled, nanoscale structures. Researchers have also shown that DNA nanotechnology can be integrated with traditional silicon processing. DNA nanoarchitectures positioned at substrate interfaces can offer unique advantages leading to improved surface properties relevant to biosensing (for instance, graphene and DNA can combine to create a stable and accurate biosensor), nanotechnology, materials science, and cell biology.

DNA is a powerful biomaterial for creating rationally designed and functionally enhanced nanostructures. Emerging DNA nanotechnology employs DNA as a programmable building material for self-assembled, nanoscale structures. Researchers have also shown that DNA nanotechnology can be integrated with traditional silicon processing. DNA nanoarchitectures positioned at substrate interfaces can offer unique advantages leading to improved surface properties relevant to biosensing (for instance, graphene and DNA can combine to create a stable and accurate biosensor), nanotechnology, materials science, and cell biology.

Feb 7th, 2013

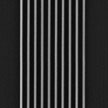

A key benefit of nanoimprint lithography is its sheer simplicity. There is no need for complex optics or high-energy radiation sources with a nanoimprint tool. Especially the nanopatterning of high refractive index optical films promises the development of novel photonic nanodevices such as planar waveguide circuits, nano-lasers, solar cells and antireflective coatings. Researchers have now developed a robust route for high-throughput, high-performance nanophotonics based direct imprint of high refractive index, low visible wavelength absorption materials.

A key benefit of nanoimprint lithography is its sheer simplicity. There is no need for complex optics or high-energy radiation sources with a nanoimprint tool. Especially the nanopatterning of high refractive index optical films promises the development of novel photonic nanodevices such as planar waveguide circuits, nano-lasers, solar cells and antireflective coatings. Researchers have now developed a robust route for high-throughput, high-performance nanophotonics based direct imprint of high refractive index, low visible wavelength absorption materials.

Jan 29th, 2013

Currently, optically absorbing nanoparticles are breaking into clinical medicine because of their ability to aid in the identification of disease with several medical imaging modalities. These nanoparticles are also used in therapeutics by triggering drug release or enhancing ablation of diseased tissues, while minimizing damage to healthy tissues. The efficiency and effectiveness of the medical imaging and therapeutics using nanoparticles depends on the ability to selectively target them to the specific tissues. A novel method only uses properties of the nanoparticles and therefore are independent of the amount of nanoparticles that reaches the target location.

Currently, optically absorbing nanoparticles are breaking into clinical medicine because of their ability to aid in the identification of disease with several medical imaging modalities. These nanoparticles are also used in therapeutics by triggering drug release or enhancing ablation of diseased tissues, while minimizing damage to healthy tissues. The efficiency and effectiveness of the medical imaging and therapeutics using nanoparticles depends on the ability to selectively target them to the specific tissues. A novel method only uses properties of the nanoparticles and therefore are independent of the amount of nanoparticles that reaches the target location.

Jan 25th, 2013

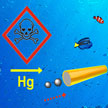

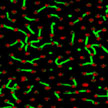

Researchers are applying various strategies to designing nanoscale propulsion systems by either using or copying biological systems such as the flagellar motors of bacteria or by employing various chemical reactions. Different practical micromotor applications, ranging from drug delivery, to target isolation and environmental remediation, have thus been reported over the past 2-3 years. Yet, there are no reports on a nanomachine-based toxicity assay approach, analogous to the use of live aquatic organisms for testing the quality of our water resources.

Researchers are applying various strategies to designing nanoscale propulsion systems by either using or copying biological systems such as the flagellar motors of bacteria or by employing various chemical reactions. Different practical micromotor applications, ranging from drug delivery, to target isolation and environmental remediation, have thus been reported over the past 2-3 years. Yet, there are no reports on a nanomachine-based toxicity assay approach, analogous to the use of live aquatic organisms for testing the quality of our water resources.

Dec 19th, 2012

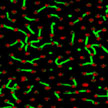

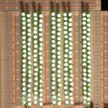

Spores are reproductive structures that have developed in nature to preserve genetic information and protect cellular components in harsh conditions and against external stresses such as nutrient deprivation, high temperatures, or radiation. Spores form part of the life cycles of many bacteria and plants. The cellular components of a spore are protected against the environment by a very robust hierarchical shell structure that allows it to survive for many years under hostile conditions found naturally that can easily and quickly kill normal cells. By developing the concept of artificial spores, researchers have been developing strategies to coat single cells with a hard, protective layer of a hard thin shells.

Spores are reproductive structures that have developed in nature to preserve genetic information and protect cellular components in harsh conditions and against external stresses such as nutrient deprivation, high temperatures, or radiation. Spores form part of the life cycles of many bacteria and plants. The cellular components of a spore are protected against the environment by a very robust hierarchical shell structure that allows it to survive for many years under hostile conditions found naturally that can easily and quickly kill normal cells. By developing the concept of artificial spores, researchers have been developing strategies to coat single cells with a hard, protective layer of a hard thin shells.

Nov 28th, 2012

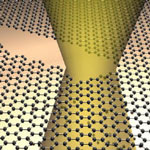

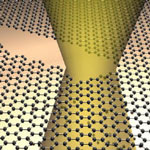

Within graphene research, transmission electron microscopy (TEM) has proven to be an extremely useful and versatile characterization tool. However, the electron beam can interact with the sample leading to its modification during the process. This may be an undesirable effect and measures to avoid this do exist. In other cases, however, electron beam-sample interactions can be useful for nanoengineering or nanomanufacturing. It is therefore crucially important to understand how a material responds to the electron beam and the environment inside a TEM. In new work, researchers have now demonstrated that damage-free sculpting of graphene with condensed electron beams is feasible.

Within graphene research, transmission electron microscopy (TEM) has proven to be an extremely useful and versatile characterization tool. However, the electron beam can interact with the sample leading to its modification during the process. This may be an undesirable effect and measures to avoid this do exist. In other cases, however, electron beam-sample interactions can be useful for nanoengineering or nanomanufacturing. It is therefore crucially important to understand how a material responds to the electron beam and the environment inside a TEM. In new work, researchers have now demonstrated that damage-free sculpting of graphene with condensed electron beams is feasible.

Nov 12th, 2012

With all the rapid progress going on in research and commercialization of flexible and transparent electronics, the obvious question is not if, but when it will be possible to build a flexible and transparent truly high performance computer. A research team has now shown, for the first time, a generic batch fabrication process to obtain mechanically flexible and transparent mono-crystalline silicon (100) from bulk wafers. The researchers demonstrate a pragmatic pathway for a truly high performance computation systems on flexible and transparent platform.

With all the rapid progress going on in research and commercialization of flexible and transparent electronics, the obvious question is not if, but when it will be possible to build a flexible and transparent truly high performance computer. A research team has now shown, for the first time, a generic batch fabrication process to obtain mechanically flexible and transparent mono-crystalline silicon (100) from bulk wafers. The researchers demonstrate a pragmatic pathway for a truly high performance computation systems on flexible and transparent platform.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed