Showing Spotlights 457 - 464 of 624 in category All (newest first):

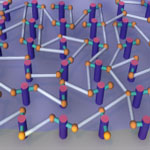

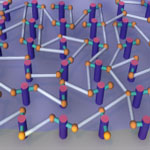

One of the true nanotechnologies that pre-dates the explosion of the popular use of the word during the past few years is Atomic Layer Deposition (ALD). This gas phase chemical process is used to create extremely thin coatings only a few nanometers thick which can be deposited in a precisely controlled way. Initially used as a technique for making a specific type of light display (electroluminescent display) smaller and more efficient, the ALD process was invented and patented by Tuomo Suntola and his co-workers in Finland in 1974 (co-incidentally, this is the year that the term 'nanotechnology' was first defined by Norio Taniguchi). The fundamental notion behind Atomic Layer Deposition is rather simple: It is a process by which an atomic layer of material can be affixed to a surface material one layer at a time. By depositing one layer per cycle, ALD offers extreme precision in ultra-thin film growth since the number of cycles determines the number of atomic layers and therefore the precise thickness of deposited film.

One of the true nanotechnologies that pre-dates the explosion of the popular use of the word during the past few years is Atomic Layer Deposition (ALD). This gas phase chemical process is used to create extremely thin coatings only a few nanometers thick which can be deposited in a precisely controlled way. Initially used as a technique for making a specific type of light display (electroluminescent display) smaller and more efficient, the ALD process was invented and patented by Tuomo Suntola and his co-workers in Finland in 1974 (co-incidentally, this is the year that the term 'nanotechnology' was first defined by Norio Taniguchi). The fundamental notion behind Atomic Layer Deposition is rather simple: It is a process by which an atomic layer of material can be affixed to a surface material one layer at a time. By depositing one layer per cycle, ALD offers extreme precision in ultra-thin film growth since the number of cycles determines the number of atomic layers and therefore the precise thickness of deposited film.

Jun 19th, 2008

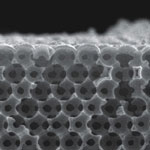

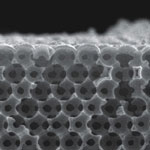

Storing the fuel that is needed to run a hydrogen car in a compact and affordable way is still a major challenge. You would need about 5 kg of hydrogen to have the same average driving range as today's cars. Since hydrogen's density is only 1/10th of a gram per liter at room temperature, that means you somehow need to pack 50,000 liters of hydrogen into your tank. There are three ways of doing this: as a high-pressure compressed gas; a cryogenic liquid; or as a solid. Rather than using hundreds of atmospheres to compress hydrogen into a tank, or cooling it down to minus 252 C to liquefy it, hydrogen storage in solid form offers the safest alternative for transportation and storage of hydrogen. Research in this area has led to metal hydrides, chemical hydrides, and physisorption-based storage, where hydrogen is adsorbed onto the interior surfaces of a porous material. The stored hydrogen can then be released by heat, electricity, or chemical reaction. Many metals are capable of absorbing hydrogen as well. The storage of gas in solids is not only an intriguing alternative for hydrogen storage but other types of gases, such as carbon dioxide and other environmentally important gases as well. Gas storage in solids is quickly becoming an important technology, with applications ranging from energy and the environment to biology and medicine. A new review article describes the types of material that make good porous gas storage materials, why different porous solids are good for the storage of different gases, and what criteria need to be met to make a useable gas storage material.

Storing the fuel that is needed to run a hydrogen car in a compact and affordable way is still a major challenge. You would need about 5 kg of hydrogen to have the same average driving range as today's cars. Since hydrogen's density is only 1/10th of a gram per liter at room temperature, that means you somehow need to pack 50,000 liters of hydrogen into your tank. There are three ways of doing this: as a high-pressure compressed gas; a cryogenic liquid; or as a solid. Rather than using hundreds of atmospheres to compress hydrogen into a tank, or cooling it down to minus 252 C to liquefy it, hydrogen storage in solid form offers the safest alternative for transportation and storage of hydrogen. Research in this area has led to metal hydrides, chemical hydrides, and physisorption-based storage, where hydrogen is adsorbed onto the interior surfaces of a porous material. The stored hydrogen can then be released by heat, electricity, or chemical reaction. Many metals are capable of absorbing hydrogen as well. The storage of gas in solids is not only an intriguing alternative for hydrogen storage but other types of gases, such as carbon dioxide and other environmentally important gases as well. Gas storage in solids is quickly becoming an important technology, with applications ranging from energy and the environment to biology and medicine. A new review article describes the types of material that make good porous gas storage materials, why different porous solids are good for the storage of different gases, and what criteria need to be met to make a useable gas storage material.

Jun 18th, 2008

You might have seen our news item from a few days ago about BMW's shape shifting concept car. NASA has worked on something much more revolutionary, called the 'Morphing' program, for a few years already. The idea is that aircraft of the future will not be built of traditional, multiple, mechanically connected parts and systems. Instead, aircraft wing construction will employ fully-integrated, nanotechnology enabled embedded 'smart' materials and actuators that will enable aircraft wings with unprecedented levels of aerodynamic efficiencies and aircraft control. Able to respond to the constantly varying conditions of flight, sensors will act like the nerves in a bird's wing and will measure the pressure over the entire surface of the wing. The response to these measurements will direct actuators, which will function like the bird's wing muscles. Just as a bird instinctively uses different feathers on its wings to control its flight, the actuators will change the shape of the aircraft's wings to continually optimize flying conditions. Active flow control effectors will help mitigate adverse aircraft motions when turbulent air conditions are encountered.

You might have seen our news item from a few days ago about BMW's shape shifting concept car. NASA has worked on something much more revolutionary, called the 'Morphing' program, for a few years already. The idea is that aircraft of the future will not be built of traditional, multiple, mechanically connected parts and systems. Instead, aircraft wing construction will employ fully-integrated, nanotechnology enabled embedded 'smart' materials and actuators that will enable aircraft wings with unprecedented levels of aerodynamic efficiencies and aircraft control. Able to respond to the constantly varying conditions of flight, sensors will act like the nerves in a bird's wing and will measure the pressure over the entire surface of the wing. The response to these measurements will direct actuators, which will function like the bird's wing muscles. Just as a bird instinctively uses different feathers on its wings to control its flight, the actuators will change the shape of the aircraft's wings to continually optimize flying conditions. Active flow control effectors will help mitigate adverse aircraft motions when turbulent air conditions are encountered.

Jun 16th, 2008

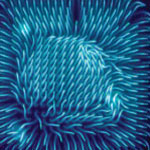

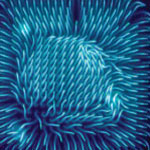

Light-emitting nanostructures are widely used for optical, photonic, chemical, and biological devices. For example, fluorescent nanoparticles are useful for biological assays and as tumor markers, chemical sensors, and organic lasers, whereas one-dimensional luminescent nanowires are exploited for novel nanoscale photonic devices such as nano-lasers and nanowire scanning microscopy. While several methods to prepare organic, inorganic, and polymeric light-emitting nanostructures have been developed, the fabrication of luminescent nanoarchitectures with a tailored morphology and pattern is still challenging. Researchers in Korea have discovered that non-luminescent polystyrene can be converted into a luminescent organic material whose emitting color can be tuned from deep blue to white by electron irradiation. They demonstrated that luminescent nanopatterns are readily fabricated only by irradiating an electron beam to the selected regions of polystyrene. In addition, the top-down irradiation approach in conjunction with self-assembled polystyrene nanostructures allows fabrication of diverse and complex luminescent nanoarchitectures.

Light-emitting nanostructures are widely used for optical, photonic, chemical, and biological devices. For example, fluorescent nanoparticles are useful for biological assays and as tumor markers, chemical sensors, and organic lasers, whereas one-dimensional luminescent nanowires are exploited for novel nanoscale photonic devices such as nano-lasers and nanowire scanning microscopy. While several methods to prepare organic, inorganic, and polymeric light-emitting nanostructures have been developed, the fabrication of luminescent nanoarchitectures with a tailored morphology and pattern is still challenging. Researchers in Korea have discovered that non-luminescent polystyrene can be converted into a luminescent organic material whose emitting color can be tuned from deep blue to white by electron irradiation. They demonstrated that luminescent nanopatterns are readily fabricated only by irradiating an electron beam to the selected regions of polystyrene. In addition, the top-down irradiation approach in conjunction with self-assembled polystyrene nanostructures allows fabrication of diverse and complex luminescent nanoarchitectures.

Jun 12th, 2008

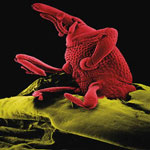

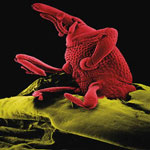

The demand for antimicrobial coatings is growing at a fast pace. In the U.S. alone, the market for these products is expected to grow from $175 million in 2005 to over $550 million in 2012. This market is not only driven by the urgent need of hospitals to reduce infections, although it would appear that they need it most: the U.S. Centers for Disease Control and Prevention (CDC) estimates that the infections acquired in hospitals alone affect approximately 2 million persons annually. In the U.S., between 44,000 and 98,000 people die every year from infections they picked up in hospitals. With a growing concern about the role of contaminated surfaces in the spread of infections such as SARS and MRSA, antimicrobial surfaces have become popular in such areas as consumer products, public spaces such as schools and offices, and public transportation. While many conventional antibacterial coatings release their antimicrobials over time (either controlled or uncontrolled) and thereby lose their antimicrobial efficiency, researchers have now developed a unique multifunctional biomimetic material comprised of carbon nanotubes, DNA, and lysozyme that has robust mechanical properties and exhibits excellent long-term antimicrobial activity.

The demand for antimicrobial coatings is growing at a fast pace. In the U.S. alone, the market for these products is expected to grow from $175 million in 2005 to over $550 million in 2012. This market is not only driven by the urgent need of hospitals to reduce infections, although it would appear that they need it most: the U.S. Centers for Disease Control and Prevention (CDC) estimates that the infections acquired in hospitals alone affect approximately 2 million persons annually. In the U.S., between 44,000 and 98,000 people die every year from infections they picked up in hospitals. With a growing concern about the role of contaminated surfaces in the spread of infections such as SARS and MRSA, antimicrobial surfaces have become popular in such areas as consumer products, public spaces such as schools and offices, and public transportation. While many conventional antibacterial coatings release their antimicrobials over time (either controlled or uncontrolled) and thereby lose their antimicrobial efficiency, researchers have now developed a unique multifunctional biomimetic material comprised of carbon nanotubes, DNA, and lysozyme that has robust mechanical properties and exhibits excellent long-term antimicrobial activity.

Jun 10th, 2008

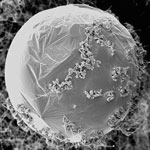

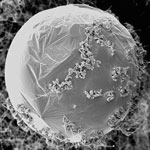

The addition of carbon nanotubes (CNTs), both single-walled and multi-walled, to various polymer matrices has produced significant improvements in strength and stiffness. Reinforcing materials based on CNTs could be used to fabricate more complex nanostructures by making them tougher and stronger. As is the case so often, and covered quite extensively here at Nanowerk nature has served as an inspiring source of various morphologies and composite materials for nanotechnology techniques. New work by Spanish scientists demonstrates the fabrication of novel nanostructures that resemble magnificent sea anemones (heteractis magnifica), aiming at increasing the rigidity and the available surface of magnetic and reinforced CNTs-based hollow capsules.

The addition of carbon nanotubes (CNTs), both single-walled and multi-walled, to various polymer matrices has produced significant improvements in strength and stiffness. Reinforcing materials based on CNTs could be used to fabricate more complex nanostructures by making them tougher and stronger. As is the case so often, and covered quite extensively here at Nanowerk nature has served as an inspiring source of various morphologies and composite materials for nanotechnology techniques. New work by Spanish scientists demonstrates the fabrication of novel nanostructures that resemble magnificent sea anemones (heteractis magnifica), aiming at increasing the rigidity and the available surface of magnetic and reinforced CNTs-based hollow capsules.

Jun 9th, 2008

Since its discovery in 2004, graphene has created quite a buzz among scientists. The reason they are so excited is that two-dimensional crystals (it's called 2D because it extends in only two dimensions - length and width; as the material is only one atom thick, the third dimension, height, is considered to be zero) open up a whole new class of materials with novel electronic, optical and mechanical properties. For instance, the ultimate size limit for a nano-electromechanical system would be a nanoscale resonator that is only one atom thick, but this puts severe constraints on the material; as a single layer of atoms, it should be robust, stiff, and stable. Graphene, the simplest of the 2D conjugated carbon nanomaterials, could fit that bill. One hurdle for researchers is that current methods for the synthesis of two-dimensional, carbon-rich networks have many limitations including lack of molecular-level control and poor diversity. In a step to overcome these obstacles, researchers have now developed new synthetic strategies for forming monolayer films of conjugated carbon, in various configurations ranging from flat 2D sheets, to balloons, tubes and pleated sheets.

Since its discovery in 2004, graphene has created quite a buzz among scientists. The reason they are so excited is that two-dimensional crystals (it's called 2D because it extends in only two dimensions - length and width; as the material is only one atom thick, the third dimension, height, is considered to be zero) open up a whole new class of materials with novel electronic, optical and mechanical properties. For instance, the ultimate size limit for a nano-electromechanical system would be a nanoscale resonator that is only one atom thick, but this puts severe constraints on the material; as a single layer of atoms, it should be robust, stiff, and stable. Graphene, the simplest of the 2D conjugated carbon nanomaterials, could fit that bill. One hurdle for researchers is that current methods for the synthesis of two-dimensional, carbon-rich networks have many limitations including lack of molecular-level control and poor diversity. In a step to overcome these obstacles, researchers have now developed new synthetic strategies for forming monolayer films of conjugated carbon, in various configurations ranging from flat 2D sheets, to balloons, tubes and pleated sheets.

Jun 3rd, 2008

The controlled patterning of surfaces with biomolecules is of great importance for future generations of micro and nano biodevices (e.g. biochips, BioMEMS, lab-on-a-chip) and biomaterials. Even with current state-of-the-art technology, this patterning requirement, i.e. the immobilization and controlled and precise placement of biomolecules, often is a limiting step in the fabrication process. Commonly applied substrate materials for such biodevice applications are inexpensive polymers; but polymer surfaces are complex to chemically pattern in larger numbers. By combining two known techniques, micro-contact printing and injection molding in a new, innovative way, researchers in Denmark have now demonstrated a surprisingly successful methodology for transferring micro- and nanoscopic patterns of functionally active proteins to polymer surfaces during injection molding of hot polymer melt.

The controlled patterning of surfaces with biomolecules is of great importance for future generations of micro and nano biodevices (e.g. biochips, BioMEMS, lab-on-a-chip) and biomaterials. Even with current state-of-the-art technology, this patterning requirement, i.e. the immobilization and controlled and precise placement of biomolecules, often is a limiting step in the fabrication process. Commonly applied substrate materials for such biodevice applications are inexpensive polymers; but polymer surfaces are complex to chemically pattern in larger numbers. By combining two known techniques, micro-contact printing and injection molding in a new, innovative way, researchers in Denmark have now demonstrated a surprisingly successful methodology for transferring micro- and nanoscopic patterns of functionally active proteins to polymer surfaces during injection molding of hot polymer melt.

Jun 2nd, 2008

One of the true nanotechnologies that pre-dates the explosion of the popular use of the word during the past few years is Atomic Layer Deposition (ALD). This gas phase chemical process is used to create extremely thin coatings only a few nanometers thick which can be deposited in a precisely controlled way. Initially used as a technique for making a specific type of light display (electroluminescent display) smaller and more efficient, the ALD process was invented and patented by Tuomo Suntola and his co-workers in Finland in 1974 (co-incidentally, this is the year that the term 'nanotechnology' was first defined by Norio Taniguchi). The fundamental notion behind Atomic Layer Deposition is rather simple: It is a process by which an atomic layer of material can be affixed to a surface material one layer at a time. By depositing one layer per cycle, ALD offers extreme precision in ultra-thin film growth since the number of cycles determines the number of atomic layers and therefore the precise thickness of deposited film.

One of the true nanotechnologies that pre-dates the explosion of the popular use of the word during the past few years is Atomic Layer Deposition (ALD). This gas phase chemical process is used to create extremely thin coatings only a few nanometers thick which can be deposited in a precisely controlled way. Initially used as a technique for making a specific type of light display (electroluminescent display) smaller and more efficient, the ALD process was invented and patented by Tuomo Suntola and his co-workers in Finland in 1974 (co-incidentally, this is the year that the term 'nanotechnology' was first defined by Norio Taniguchi). The fundamental notion behind Atomic Layer Deposition is rather simple: It is a process by which an atomic layer of material can be affixed to a surface material one layer at a time. By depositing one layer per cycle, ALD offers extreme precision in ultra-thin film growth since the number of cycles determines the number of atomic layers and therefore the precise thickness of deposited film.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed