| Posted: Aug 18, 2014 |

Carbon nanotubes to improve resin coatings

|

|

(Nanowerk News) Resin coatings are widely used in various sectors, like the aeronautical and automotive sectors, and in the structural components of aircraft and vehicles, in particular. Research by the UPV/EHU-University of the Basque Country has used carbon nanotubes to improve the properties of these coatings ("Dispersion of carbon nanotubes in nanostructured epoxy systems for coating application").

|

|

The research has been conducted within the POCO European project and seeks to come up with strategies to spread carbon nanotubes properly throughout different polymers. Carbon nanotubes improve the conductivity of these coatings, repair any scratches they may have and have excellent mechanical properties: they are tough and rigid and, what is more, conduct electricity. Epoxy resins, by contrast, are insulating materials. So if these nanotubes are added to them, the coatings are also turned into conductors.

|

|

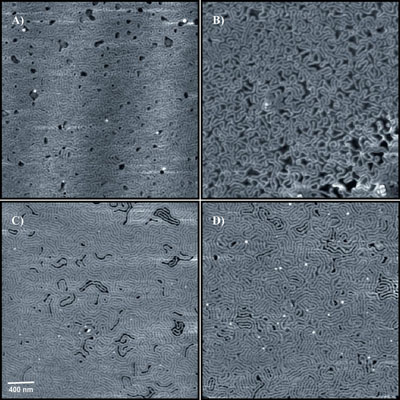

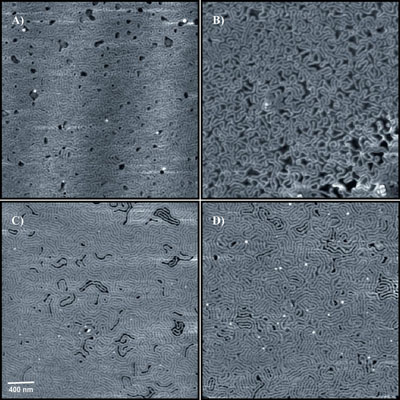

| On the left, applying epoxy and nanotube coating using a spray. On the right, an image of a nanostructure (3 x 3 µm) that has 0.2 % of nanotubes and 5 % of copolymers. (Image: UPV/EHU)

|

|

“However, to transmit or enhance these properties better, the carbon nanotubes must be properly spread throughout the material,” pointed out the UPV/EHU chemist Galder Kortaberria.

|

|

But this advantage turns into a problem for the nanotubes because they tend to form clusters and often group together. So they cause problems when it comes to being expanded across a matrix. So for that very reason strategies or methods are needed to help the carbon nanotubes spread as much as possible within the polymer matrix.

|

|

A new development: the use of copolymers

|

|

Different strategies are used to spread the carbon nanotubes across the polymer matrix. Firstly, electric and magnetic fields. Since carbon nanotubes are conductors, they position and align themselves in the desired direction when they come up against an electric field. What is more, the surface of these nanotubes can be changed by means of chemical treatments until a specific affinity or compatibility is achieved with the epoxy.

|

|

Finally, this UPV/EHU research team has put forward a new strategy: the use of copolymers, in other words, blocks of two different polymers joined to each other by means of chemical bonds. In this case, the styrene-butadiene-styrene copolymer was used.

|

|

The first step was to chemically transform one of the blocks of the copolymer (the butadiene in this case), to make it compatible with the epoxy resin matrix. The other block, by contrast, was divided, but as it has a covalent bond with the butadiene, the division was on a nanometric scale and nanostructures were produced.

|

|

“That way the carbon nanotubes disperse much better across the epoxy matrix, without forming clusters,” pointed out Kortaberria. In general, “all the coatings we prepared were more stable than the ones based on the epoxy alone. The most stable coating is the one that has 0.2% of carbon nanotubes,” he added.

|

|

The research team saw that the coating properties could be improved by varying the quantities of copolymers and nanotubes, thermal stability and behaviour, in particular, when handling temperature, and that coatings suitable for industry could be designed.

|

|

“The spread of the nanotubes has improved considerably with the use of copolymers, and the properties of the epoxy resin-based coatings are maintained; in some cases they have even improved,” asserted Kortaberria. “All this makes it possible to produce coatings suitable for industry with enhanced characteristics,” he added.

|