| Posted: Apr 30, 2015 |

Why, and how, computational research matters is changing materials science

|

|

(Nanowerk News) To stay competitive, businesses and governments are constantly looking for materials that will open the door to new technologies or sources of energy. Materials that will make their products faster, lighter, stronger or more efficient. Whoever develops those materials first will have a significant edge over the competition.

|

|

And in recent years it has become increasingly apparent that the key to getting that edge, and maintaining it, is computational research.

|

|

“Problems that used to take years to solve can now be solved in a month,” says Srikanth Patala, a materials science and engineering researcher at NC State.

|

|

Computational research uses complex models in a variety of ways, all of which advance materials science and engineering.

|

|

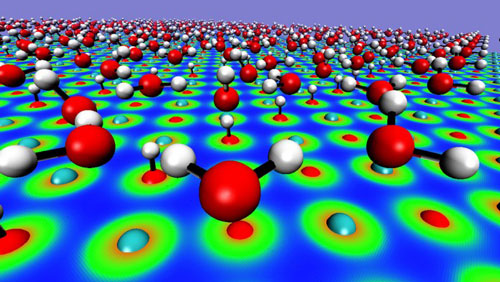

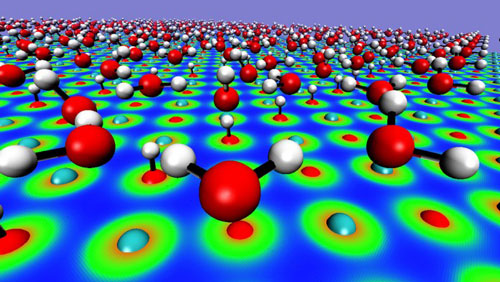

| A computer simulation of how calcium oxide interacts with water vapor. The work was done to predict the thermodynamic stability of the solid surface in contact with a reactive gas and how this stability changed through control of external conditions. (Image: Doug Irving)

|

|

“These computational models can help researchers understand the outcome of an experiment, identify the most promising avenues for future experiments, and give us insight into processes that can’t be easily explored in the lab,” says NC State researcher Don Brenner, a pioneer in the field of computational materials research who has been publishing in the field since the late 1980s. “For example, computational research helps us understand the behavior of materials in nuclear reactors, which are exposed to high levels of heat and radiation.”

|

|

“And we can now use models to design new materials that have a specific set of characteristics for use in any given application,” Patala says.

|

|

“By using computational models, we can evaluate hundreds or more possible material combinations,” Brenner explains. “It would take years to evaluate those combinations using traditional experimental methods, but we can narrow it down to a handful of the most promising materials combinations.”

|

|

“There are a lot of people at NC State who embrace computational research as a way to gain meaningful insight into how to design new materials,” says Doug Irving, another materials researcher at NC State. “Ultimately, this gives our researchers a big advantage over researchers who don’t use these capabilities.”

|

|

For example, Brenner’s lab recently led an effort to understand what causes metal oxide scales to deposit on the fuel rods in nuclear reactors – a job that would be both dangerous and incredibly difficult (if not impossible) using traditional experimental techniques.

|

|

“What we found will make it possible to develop new techniques for eliminating these scales, which would make the reactors more efficient and extend the lifetime of nuclear fuel rods,” Brenner says.

|

|

But computational research in materials science extends well beyond nuclear power.

|

|

“We do work on optical and electronic materials, structural materials, energetic materials and soft materials,” Irving says. “We’re talking about applications in everything from electronics and LEDs to pharmaceuticals and biomedical devices.”

|

|

In other words, theoretical models can lead to practical solutions for real world problems.

|