| Posted: Jun 02, 2015 |

Realistic computer model of battery electrodes

|

|

(Nanowerk News) A research team has developed a new approach for more realistic computer models of battery electrodes. They combined images from synchrotron tomography that capture three-dimensional structure at micron resolution with those from an electron microscope that can even resolve nanometre-scale features over a small section. They were able to transfer these nano-features to areas beyond the section using a mathematical model. Properties and processes within battery electrodes can now be simulated highly realistically using this method.

|

|

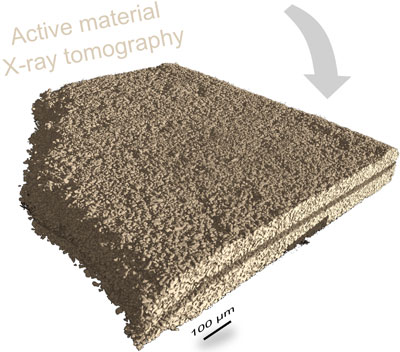

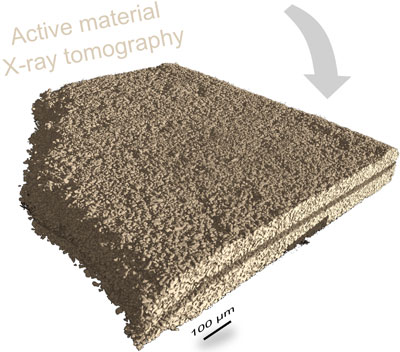

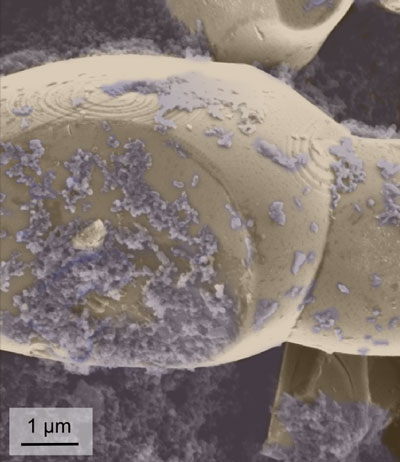

| To obtain the 3D structure of the battery electrode on a micormeter scale, snchrotron tomography at BESSY II was used. (Image: L. Zielke/S. Thiele)

|

|

Batteries need to be even lighter, offer higher performance, and cost less if they are to power automobiles on a large scale and store energy from the wind and sun one day. One means of accelerating this development is to use Virtual Materials Design. With an appropriate computer programme, materials with a wide range of various features can be virtually manufactured and virtually tested with a couple of mouse clicks – that is the idea. The problem lies in not having a good approximation of reality, though. “The material that you invent on the computer needs to actually be able to be produced in the end, of course. That is possible only if the material is based on real structural parameters”, explains HZB researcher Dr. Ingo Manke.

|

|

Real data of 3D structure combined with mathematical model

|

|

In order to model systems of materials for battery electrodes on the computer based on realistic structural parameters, Manke and his colleague Dr. André Hilger from the HZB Institute of Applied Materials have now developed a new approach together with a team from Brigham Young University (USA) and the University of Freiburg.

|

|

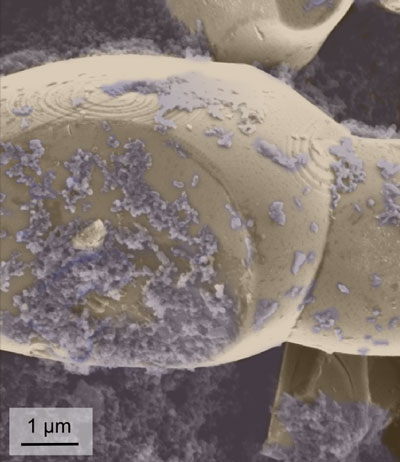

| Nano-features of the structure were recorded with a scanning electron microscope over a much smaller section of the material. (Image: L. Zielke/S. Thiele)

|

|

They combined two different tomographic processes using what is referred to as a multiscale approach. First, they analysed a modern LiCoO2 battery electrode using synchrotron tomography at BESSY II to obtain information about the three-dimensional structure at the micron scale. In addition, they recorded nano-features at one-thousand times finer resolution using a scanning electron microscope with a focussed ion beam (SEM/FIB tomography), but over a much smaller section of the material. This information about the nanostructure was able to be successfully transferred to the much larger structure captured in the synchrotron tomogram by using a mathematical model developed by Prof. Dean R. Wheeler (Brigham Young University).

|

|

Virtual materials design

|

|

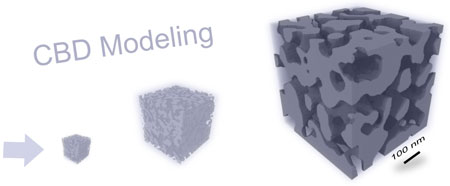

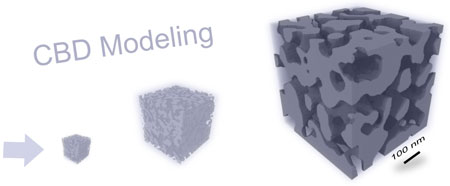

“You can imagine it as being like a tapestry, where its detailed structure continuously repeats itself over the entire wall. Only in this case, the detailed structure does not repeat itself, but instead is being continuously re-calculated”, explains Manke.

|

|

| By using a mathematical model, information about the nanostructure was successfully transferred to the much larger structure. (Image: L. Zielke/S. Thiele)

|

|

The new approach enables features that appear in real batteries to be carried over to a highly realistic computer model so that important processes like the distribution of electrical current or ion transport can be investigated virtually. The next step will be to incrementally change the models of these structures to improve the current distribution or ion transport, for example. “In the end, the features that we have optimised on the computer also need to be able to be produced in the laboratory. Then we will test how well the procedure really works”, says Manke.

|

|

The results of this study have been published in the renowned journal Advanced Energy Materials ("Three-phase multiscale modeling of a LiCoO2 cathode – Combining the advantages of FIB-SEM imaging and X-ray tomography"). The work was a continuation of a previous study by the research teams that was published in the same journal last year ("A Combination of X-Ray Tomography and Carbon Binder Modeling: Reconstructing the Three Phases of LiCoO2 Li-ion Battery Cathodes").

|