| Posted: Mar 23, 2016 |

Solar water splitting using particulate photocatalyst sheets

(Nanowerk News) Researchers at the University of Tokyo have achieved a solar-to-hydrogen energy conversion efficiency of 1.1% using particulate photocatalyst sheets developed by the research group (Nature Materials, "Scalable water splitting on particulate photocatalyst sheets with a solar-to-hydrogen energy conversion efficiency exceeding 1%"). The photocatalyst sheet can potentially produce a large quantity of solar hydrogen inexpensively owing to its scalability and low fabrication cost.

|

|

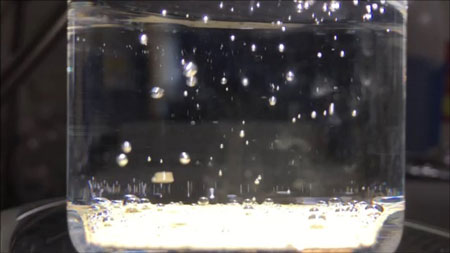

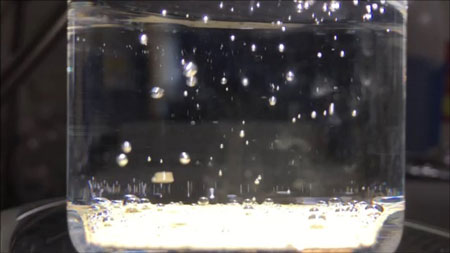

| Water splitting on a particulate photocatalyst sheet. A particulate photocatalyst sheet based on a hydrogen evolution photocatalyst and an oxygen evolution photocatalyst embedded into a conductive layer supported by a glass plate splits water and evolves bubbles of hydrogen and oxygen when immersed in water and irradiated by the sun. (Image: Domen-Minegishi Laboratory)

|

|

Innovative production technologies of chemicals based on renewable energy while not heavily relying on fossil fuels are essential in order to solve the issue of global warming and realize sustainable low-carbon societies. Solar water splitting is a technology that utilizes a photocatalytic material to split water and convert solar energy into hydrogen fuel. This photocatalytic reaction forms the foundation of the artificial photosynthesis process to produce valuable chemicals from renewable solar hydrogen and carbon dioxide. However, it is still challenging to develop a technology that combines high solar-to-hydrogen energy conversion efficiency (STH), high scalability, and low fabrication cost.

|

|

Professor Kazunari Domen’s research group at the University of Tokyo Graduate School of Engineering has developed particulate photocatalyst sheets consisting of two kinds of particulate photocatalysts and conductive materials fixed onto glass.

|

|

The particulate photocatalyst sheet is prepared by a particle transfer process: first, a mixture of two different particulate photocatalysts for production of hydrogen and oxygen under visible light is spread on glass plates, on top of which a conductive layer is deposited. Subsequently, the composite of the particulate photocatalyst layer and the conductive layer is peeled off. This fabrication process allows the reduction of the resistance between the photocatalyst particles and the conductive layer.

|

|

“The photocatalyst sheet we developed can decompose water into hydrogen and oxygen on the same surface without external power supply when being immersed in water and illuminated by the sun. Therefore, the photocatalyst sheet is scalable as is without loss of activity,” says Domen. He continues, “Furthermore, in anticipation of scaling-up to mass production needed for future practical applications, we have developed simple and scalable photocatalyst sheet prints by means of screen-printing that evolve hydrogen and oxygen steadily. The cost to print particulate photocatalysts is directly reflected in the fabrication cost of particulate photocatalyst sheets. We therefore expect significant cost reduction in the fabrication of particulate photocatalyst sheets by simple technologies such as screen-printing.”

|