| Posted: Apr 20, 2016 |

Nanometric positioning goes the distance

(Nanowerk News) Filling a major gap in precision control for applications from semiconductor fabrication to manipulations of living cells, A*STAR researchers have developed a frictionless drive system that provides nanometer precision over millimeters of travel without complicated feedback control ("Millimeters-Stroke Nanopositioning Actuator With High Positioning and Thermal Stability"). The system, developed by Daniel Tat Joo Teo and colleagues from the A*STAR Singapore Institute of Manufacturing Technology, has the potential to revolutionize experimentation and fabrication at the nanoscale.

|

|

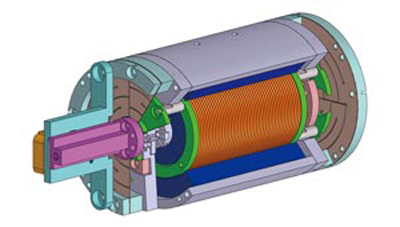

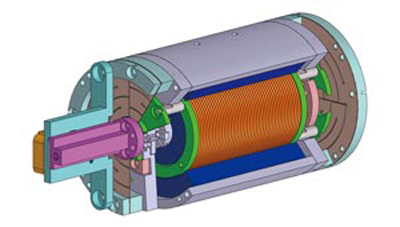

| The flexure-based electromagnetic linear actuator (FELA) with nanometer positioning precision over a few millimeters of travel. (© IEEE)

|

|

Observing, manipulating and creating at the nanometer level can appear straightforward on paper, but in practice researchers and manufacturers encounter many obstacles when trying to realize nanoscale concepts. While some of these obstacles, such as observing nanoscale features, have been comprehensively resolved, others, such as our ability to control the position of nanoscale objects under the microscope, have remained persistent obstacles.

|

|

Although various nanometer precision position control technologies have been developed, they invariably require highly complex feedback control loops and specialized precision-engineered mechanisms to achieve positioning accuracy and offer only short, micrometer travel distances.

|

|

The main limitation of existing nanometric positioning systems is their non linearity — the position of the actuator head does not change consistently with the driving input, such as an electric voltage or current. Instead, the system needs to measure the variable displacement using sensors, which then feed back into the control system to adjust movement. This results in complexity and cost which makes efforts to incorporate additional travel capability extremely challenging.

|

|

Tat Joo Teo and colleagues from the Singapore Institute of Manufacturing Technology went back to the drawing board to develop a better solution from scratch. “We developed an electromagnetic drive consisting of fixed permanent magnets inside and around a moving wire coil,” says Teo. “The coil moves by electromagnetic Lorentz force when a current is applied, with contactless and frictionless motion.” The coil is connected to a drive shaft and is held in place by flexible figured steel plates that act as flexure joints. “The electromagnetic drive and flexure joints are highly linear in their motion response, resulting in theoretically infinite positioning resolution and a travel range of a few millimeters but limited only by the linear range of the flexure joints,” he notes.

|

|

As its motion is linear, the ‘flexure-based electromagnetic linear actuator’ (see image) requires no positioning sensors or complex feedback control loops, yet can achieve nanometer precision using a simple electrical current input.

|

|

“Our system can be readily reconfigured, making it highly adaptable to any process as an attractive cost-effective solution for many applications, particularly for semiconductor technology manufacturers,” says Teo.

|