| Posted: Feb 08, 2017 |

Turning the world's smallest screw

(Nanowerk News) Structures that just may be the world’s smallest screws have been fabricated by researchers from A*STAR (Journal of the American Chemical Society, "Nanoscrews: Asymmetrical etching of silver nanowires").

|

|

The coiled thread on a screw is among the ‘chiral’ structures’ whose mirror image is different from the original. When reduced to the nanometer scale, these structures could have an important role in nanosensor technology. However, making a screw out of a straight wire is no small task, even in the macroscopic world. Making it on the nanoscale has previously used bottom-up methods that grow or assemble the structure in a gas or solution. But such approaches can be complicated, slow and expensive.

|

|

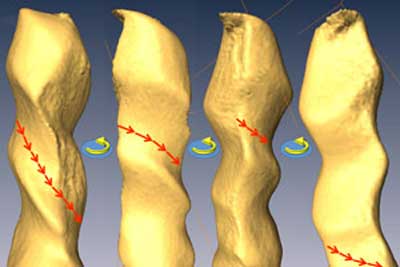

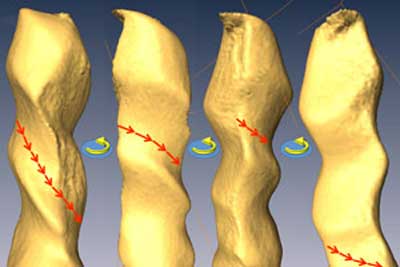

| A simple etch method can create nanoscale screws useful for sensors. (© ACS)

|

|

Jun Wei from A*STAR’s Singapore Institute of Manufacturing Technology and co-workers from the A*STAR Institute of Materials Research and Engineering, Nanyang Technological University and Nanjing Tech University in China, developed a simpler method that uses etching techniques to convert a straight nanowire into a screw.

|

|

The team created 10-micrometer silver nanowires, 80 nanometers in diameter and with five sides. The structures were attached to a silicon substrate and then placed into a solution of silver nitride in ethylene glycol at 80 degrees Celsius for 20 minutes. The sample was then rinsed clean and the process repeated five times.

|

|

When the resultant wires were imaged using a scanning transmission electron microscope the team observed smooth ridges and grooves reminiscent of screw threads. Interestingly, such a structure was not evident when a single-step etch was used.

|

|

Etching usually works along specific crystallographic directions, leading to symmetric structures, so the team wanted to know how equivalent crystal facets could be etched in an anisotropic way. They propose that this unusual etching mode might begin with the creation of pits at the boundaries between the five crystallographic regions that make up the pentagonal nanowire. These pits merge at an angle, driven by the propensity to minimize the surface energy, and thus create ridges and grooves that spiral around the nanowire.

|

|

“This selective etching is driven by a faster etching rate at some defect locations on the silver nanowire,” says Wei. “Thus, we can convert a regular structure into non-symmetrical one.”

|

|

Such chiral nanostructures have a much larger surface area than a straight nanowire of similar size. This makes them potentially useful for sensing applications. “We next hope to use the nanoscrews in the fabrication of sensors and transparent conductors,” says Wei.

|