| Posted: Jul 03, 2017 | |

Shape memory composites for 3D-printed photoresponsive devices(Nanowerk News) Researchers in Singapore have fabricated 3D printed photoresponsive shape memory devices through combining fused deposition modeling (FDM) printing technology and photoresponsive shape memory composites based on polyurethane and carbon black (PUCB). |

|

| Reporting their findings in Advanced Materials ("3D Printed Photoresponsive Devices Based on Shape Memory Composites"), the team successfully demonstrated the 3D printing of a 30 × 30 × 30 mm cube with 4 × 4 mm frame with photoresponsive shape memory behavior by commercial FDM printer. | |

|

|

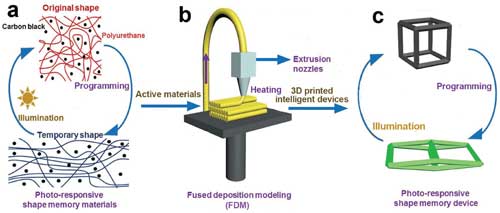

| a) Photoresponsive shape memory behavior of 3D printing materials based on carbon black and PU. b) 3D printed device fabricated by fused deposition modeling. 3D printing materials are extruded from nozzle and moved in both horizontal and vertical directions by controlled stepper motors to print devices on a glass panel by layer-by-layer deposition. c) Photoresponsive shape memory behavior of 3D printed device. (© Wiley-VCH Verlag) (click on image to enlarge) | |

| The authors applied FDM in order to avoid the influence of UV illumination in the 3D printing process of photoresponsive devices. The addition of carbon black with an efficient photothermal conversion endows the 3D printed shape memory devices with excellent photo response. | |

| The team points out that the printing of such a frame resembling the crystal structure of NaCl by FDM printer constitutes a huge challenge due to the hollow and overhanging components of the structure. | |

| When the temperature of the nozzle is above the melting point of PUCB, the thermoplastic filament would be in the melt state, thus enabling its extrusion from the nozzle for printing cubic frame by a FDM printer. After heating, adding external force, and cooling for 3D printed cubic frame, the temporary shape of the cubic frame was fixed from the original state. | |

| Interestingly, natural sunlight can also trigger the shape memory behavior of these 3D printed devices due to photoresponsive shape memory property of printing materials PUCB. | |

|

|

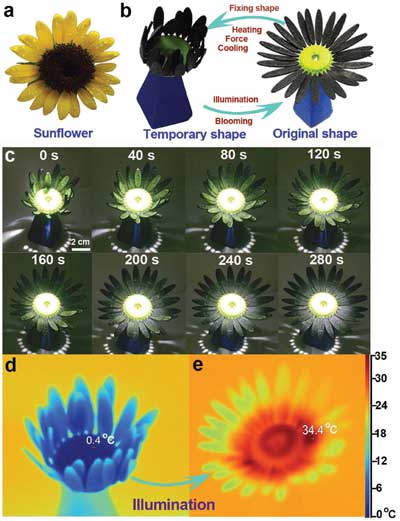

| a) The real image of sunflower. b) Phototriggered shape memory behavior of 3D printed sunflower from closed to opened state like the blooming of flowers. c) The different deformation of 3D printed sunflower with different illumination time under 87 mW cm-2 of light intensity, which were obtained every 40 s. During illumination, sunflower turned from bud to bloom. d) The infrared image of sunflower before the illumination displaying its temperature as 0.4°C. e) The infrared image of sunflower after the 280 s of illumination, showing its temperature increased to 34.4°C. (© Wiley-VCH Verlag) (click on image to enlarge) | |

| "The development of this facile printing strategy will provide tremendous opportunities for the design and fabrication of personal stimuli-responsive devices, which can be widely applied in the field of attractive and highly personalized biomimetic smart devices and soft robotics," the authors cocnlude. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |