| Posted: Jul 03, 2017 | |

Ultrasensitive pressure sensor based on an air-bubbled ultralight graphene block(Nanowerk News) Reporting their findings in ACS Applied Materials & Interfaces ("Ultrasensitive Pressure Sensor Based on an Ultralight Sparkling Graphene Block"), researchers in China have developed an ultrasensitive pressure sensor on the basis of the unique sparkling graphene block. |

|

| Flexible and highly sensitive flexible sensors are key elements in advanced wearable or implantable sensing devices. With the ability to transduce external stimuli (e.g., pressure and temperature) into electronic signals, sensors have attracted a great deal of attention because of its wide potential applications. | |

|

|

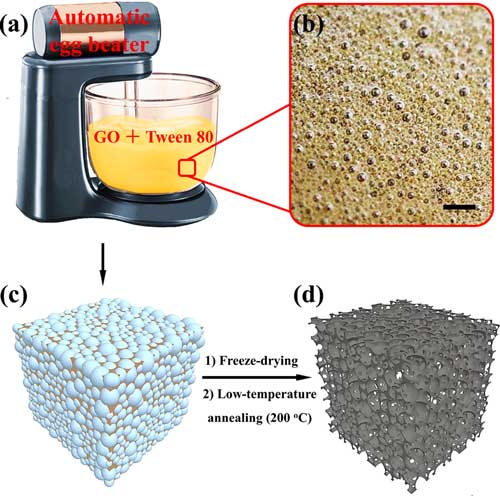

| Illustrations for the Preparation of SGB: (a) 50 mL of GO Dispersion (5 mg mL-1) and 7 mL of TWEEN 80 (100 mg mL-1, Dissolved in Ethanol) Mixed under Stirring Using an Automatic Egg Beater at 1300 rpm for 10 min, (b) Enlarged View of the Gas Bubbles in the Mixture (Scale Bar, 1 mm), (c) Homogeneous Mixture of Air Bubbles and GO, and (d) SGB Obtained after Freeze-Drying and Heated at 200°C. (© ACS) (click on image to enlarge) | |

| In pressure sensors, sensitivity is a crucial parameter for accurate monitoring. There are mainly four types of pressure sensors based on piezoelectric, capacitive, field-effect sensing mechanisms, and piezoresistive. | |

| Owing to its unique electrical and mechanical characteristics, graphene is promising as the building block for assembled architectures approaching application in piezoresistive sensors. | |

| In this new work, the team demonstrates an ultrasensitive pressure sensor based on a fully air-bubbled ultralight graphene block, using a simple sparkling approach toward large-scale production. The specifically prepared sparkling graphene block (SGB) has excellent elasticity, which can rebound a steel ball with ultrafast recovery speed (∼1085 mm s-1) and features particular well-connected hierarchical bubble cavities with a low density of 3.7 mg cm-3. | |

| As the researchers point out, The SGB shows a small-strain Young’s modulus of 1.1 kPa and a remarkable low maximum compressive stress of 2 kPa at 95% compressive strain. The pressure sensor based on the SGB demonstrates a superior pressure sensitivity of 229.8 kPa-1 to extremely low pressure (0-0.1 kPa), which is the highest among other graphene-based piezoresistive pressure sensors. | |

| "As a result, the SGB pressure sensor can detect extremely tiny disturbance such as breeze beyond the touch with a dandelion, a feather, and a hair," the authors conclude their report. "With the sensitive performance in response to the bending and twisting process, the SGB exhibits great potential for multifunctional sensing applications." |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |