| Posted: Jul 08, 2017 | |

Tuning thermal expansion with origami metamaterials(Nanowerk News) In new work just published in Advanced Materials ("Origami Metamaterials for Tunable Thermal Expansion"), researchers at Harvard University have combined experiments and simulations to demonstrate that origami metamaterials provide a new platform for the design of systems with a wide range of coefficients of thermal expansion. |

|

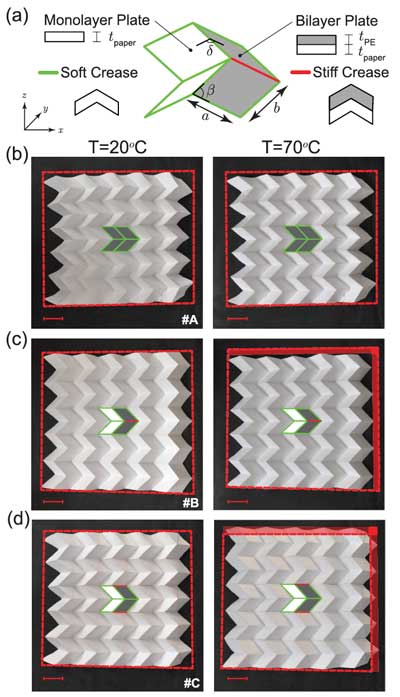

| In particular, the team shows that by controlling the arrangement of single and bilayer facets, the stiffness of the creases, and the geometric parameters, they can achieve a variety of qualitatively different responses upon variations in temperature. | |

| From engines, buildings, and solar energy systems to lenses, spacecrafts, and tooth fillings, many systems require components capable of achieving targeted area/volume changes in response to variations in temperature. | |

| While some of them – including bearings and structures with high tolerances – benefit from materials whose area/volume is unaltered by changes in temperature, others – such as piping connections and tooth fillings – require materials that match the thermal expansion of the surrounding environment. | |

| This inspired Prof. Katia Bertoldi and her group to explore a simple origami tessellation, the Miura-ori, and combine experiments with simulations to demonstrate that this system can also provide a platform for the design of materials with a wide range of coefficients of thermal expansion. | |

|

|

| Origami metamaterials for tunable coefficient of thermal expansion. a) Schematic of the unit cell of the considered origami metamaterial. The structure is comprised of both single-layer (white) and bilayer (gray) plates, connected by a combination of soft (green) and stiff (red) creases. Top views of samples b) #A, c) #B, and d) #C at 20°C (left) and at 70°C (right). For each structure, a schematic of the unit cell is highlighted in the center of the sample. The red dashed box indicates the projected area of the sample at 20°C. (Scale bars: 30 mm). (© Wiley-VCH Verlag) | |

| The structure proposed by the team presents two main differences with respect to existing systems: first, it is possible to tune its thermal response in situ simply by changing the opening angle δ, without the need to fabricate a new structure; second, it is intrinsically nonporous and therefore can be preferred in applications where a separation between two regions is required. | |

| Additionally, while the scientists in this paper focused on structures at centimeter scale made of paper and polyethylene, the proposed design can be potentially extended to different materials and length scales. | |

| "As such, our study provides new opportunities for the design of materials and components capable of achieving extreme and customizable thermal expansion properties that can be of particular interest for applications in aerospace, optics, energy, and microelectronics," the augthors conclude their work. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |