| Posted: June 1, 2009 |

Biomimetic-engineering design can replace spaghetti tangle of nanotubes in thermal materials |

|

(Nanowerk News) Nanoelectromechanical systems (NEMS) devices have the potential to revolutionize the world of sensors: motion, chemical, temperature, etc. But taking electromechanical devices from the micro scale down to the nano requires finding a means to dissipate the heat output of this tiny gadgetry.

|

|

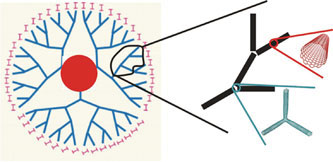

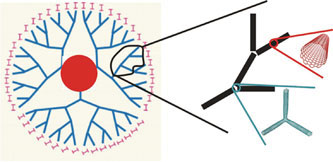

In a paper appearing in the March 26 issue of Nano Letters, Professor Markus Buehler and postdoctoral associate Zhiping Xu of MIT’s Department of Civil and Environmental Engineering say the solution is to build these devices using a thermal material that naturally dissipates heat from the device’s center through a hierarchical branched network of carbon nanotubes. The template for this thermal material’s design is a living cell, specifically, the hierarchical protein networks that allow a cell’s nucleus to communicate with the cell’s outermost regions.

|

|

“The structure now used when designing materials with carbon nanotubes resembles spaghetti,” said Buehler, who studies protein-based materials at the nano and atomistic scales with the goal of using biomimetic-engineering principles to design human-made materials. “We show that a precise arrangement of carbon nanotubes similar to those found in the cytoskeleton of cells will create a thermal material that effectively dissipates heat, which could prevent a NEMS device from failing or melting.”

|

|

NEMS devices are characterized by extremely small, high-density heat sources that can’t be cooled by traditional means. Even the microelectromechanical systems (MEMS) devices used in automobiles and electronics are hard to cool, because conventional thermal management strategies such as fans, fluids, pastes and wiring often don’t work at these small scales; heat buildup in MEMS frequently leads to catastrophic device failure, which limits the reliability of larger systems.

|

|

| The figure illustrates a hierarchical network of carbon nanotubes mimicking the protein network in a living cell to connect a small heat source (red area) to a larger area that serves as a heat sink. (Image: Markus Buehler, MIT)

|

|

But the number of heat-conducting fibers or carbon nanotubes (CNTs) that can be connected to the heat source at the center of a NEMS device is limited by the physical size of the heat source itself. Buehler and Xu demonstrate that a simple geometric structure — a branched-tree hierarchy of at least two branches sprouting off each branch — is far more effective at heat dissipation than the non-hierarchical “spaghetti” of most existing CNT-based material.

|

|

They show that a single fiber (or branch) connected to the heat source, with 99 additional branched links between it and the heat sink, will provide the same dissipation effect as if 50 long fibers were connected directly to the heat source. If five carbon nanotubes are arranged in direct connection to the heat source, each of which uses this branched-tree hierarchical structure, the heat dissipation will be the equivalent of 250 direct connections from the heat source to an external heat sink.

|

|

|

|

“Our paper provides a breakthrough in the understanding of how nanostructural elements can be utilized effectively to bridge scales from the nano to macro through formation of hierarchical structures,” said Xu. “The results could change the way nanodevices are designed and fabricated by enabling technological innovations for highly integrated systems.”

|

|

This research is funded by DARPA (the U.S. Defense Advanced Research Projects Agency) and the MIT Energy Initiative.

|