| Posted: July 28, 2009 |

Graphene nanocomposite material could help automakers meet fuel efficiency standards |

|

(Nanowerk News) Michigan State University (MSU) researchers have developed a composite material modified with nanoparticles that is economical and could also help automakers meet the new fuel efficiency standards recently announced by President Barack Obama.

|

|

The new nanocomposite is based on a nanomaterial invented at MSU – xGnP® Graphene Nanoplatelets – which is added to sheet molding compound (SMC) to make it stronger and tougher, as well as electrically conductive. SMC is used in many industrial applications, especially the manufacture of automobile parts. Since the new nanocomposite is stiffer and stronger, less of it can be used to manufacture finished parts. And that could be a boon to automobile manufacturers who are faced with meeting the new automotive fuel efficiency standards, which will require automakers to increase fuel efficiency by more than 5 percent per year starting in 2012. To achieve these standards, automotive companies will need to take considerable weight out of their future cars (while still maintaining structural safety), and this SMC formulation could be a significant help.

|

|

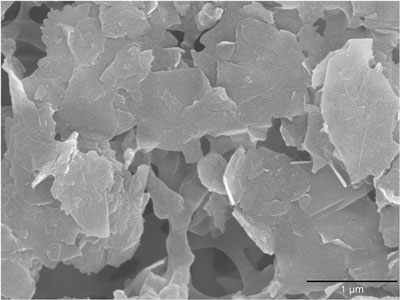

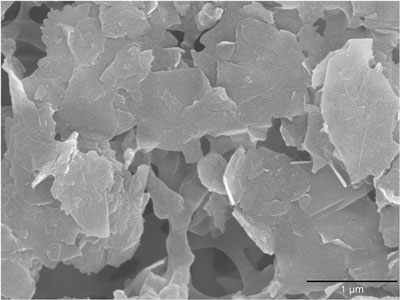

| graphene nanoplatelets

|

|

The research was led by Lawrence T. Drzal, University Distinguished Professor in the Department of Chemical Engineering and Materials Science, director of MSU’s Composite Materials and Structures Center (CMSC) and chief scientist at XG Sciences, Inc., a start-up company headquartered in East Lansing, Mich.

|

|

Research shows that when about 3 percent of the new material is added to the standard SMC formulation, the resulting composite material is stronger (by 40 percent) and stiffer (by 20 percent), and also has better impact strength (an increase of 80 percent).

|

|

|

|

“In addition to the increase in strength,” says Drzal, “this new nanocomposite is electrically conductive enough so that it can be electrostatically painted without requiring the additional coating process now used to paint most SMC parts. This will save money in manufacturing and reflects our approach toward overall cost effectiveness with these new advanced materials.”

|

|

“This new SMC is just one of several improved composite materials that can be made with our xGnP® Graphene Nanoplatelets,” says Michael R. Knox, CEO of XG Sciences. “We look forward to the introduction of a whole family of advanced composite materials based on our products. We are now shipping materials to customers around the world and are working closely with several large potential users to get these new composites into production.”

|