| Posted: February 9, 2007 |

Car companies like Ford increasingly getting on the nanotechnology bandwagon |

|

(Nanowerk News) Many components used by the car industry will benefit from nanotechnology – reducing car weight, optimizing combustion and cleaning exhaust fumes, enhancing material functions such as scratch-resistant or self-healing paints, abrasion resistant tires, and improving cost efficiencies. Not to mention future fuel cell technology for hydrogen powered cars. Furthermore, the significance of automobile electronics will further increase and the automobile industry will be a driving force for bringing nanoelectronic innovations to application maturity. By some estimates, by the year 2015 approx. 70% of a car's components will use nanotechnology in some form or other.

|

|

The R&D departments of car companies are working with nanotechnology to develop stronger and lighter structural materials, such as plastic composites. These plastics use nanoparticles as fillers that reduce weight and increase strength. Researchers are making aluminum castings stronger and better performing, such as engine blocks. Paints and glass that block the sun's infrared radiation and actually clean themselves of dirt and grime are being researched.

|

|

In recent news, Ford announced that it will accelerate its nanotechnology R&D into lightweight metals and stronger plastic materials in cooperation with Boeing and Northwestern University.

|

|

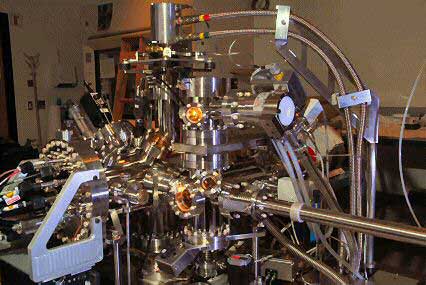

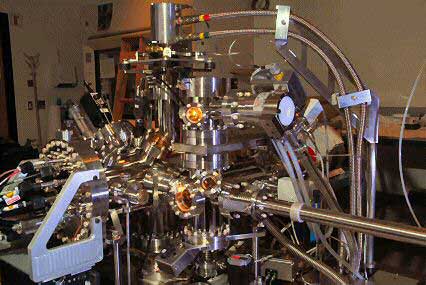

Called the Local Electrode Atom Probe (LEAP), this tool, which is housed at Northwestern University, enables companies like Ford and Boeing to cut in half the amount of time it takes to analyze the molecular makeup of metals and plastics and determine ways to tailor the material to make lighter weight and more durable parts.

|

|

LEAP at Northwestern

|

|

Ford is also developing nanofluids, which involves dispersing nano-scale particles into vehicle liquids, such as coolants and engine oil, lubricants and transmission fluids. Ford scientists have found that sprinkling nanoparticles into these liquids reduces friction and increases thermal conductivity – both of which allow the liquid to operate at lower temperatures.

|

|

“Since nanotechnology can impact such a wide range of vehicle components and functionalities, it provides a versatile toolkit for meeting anticipated customer expectations for performance, comfort, convenience and quality,” said Erica Perry Murray, on-campus Ford Boeing Northwestern alliance manager. |

|

The alliance between Ford, Boeing and Northwestern paves the way for the three to research commercial applications of nanotechnology. The agreement is designed to pave the way for future advancements in transportation, specialty metals, thermal materials, coatings and sensors.

|