| Posted: January 20, 2010 |

Mesoporous materials: Three times the connection |

|

(Nanowerk News) Mesoporous materials have pore sizes of just 2–50 nanometers. Now, the first such material consisting of three unlinked, but interpenetrating, pore systems has been synthesized by researchers at the Institute of Bioengineering and Nanotechnology of A*STAR, Singapore. Jackie Ying and her co-workers explain that since the three channel systems are separated from one another by silica walls, the material is an ideal candidate for applications in drug delivery, catalysis, and separation technologies ("A tri-continuous mesoporous material with a silica pore wall following a hexagonal minimal surface").

|

|

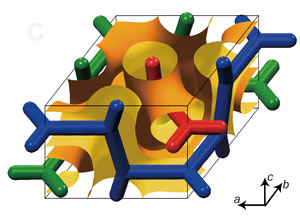

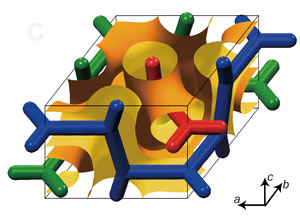

The ‘tri-continuous network’ material (Fig. 1) represents a new class of materials, with an increase in complexity over existing bi-continuous network materials that have only two interpenetrating pore systems. Ying says that the interwoven and unconnected tri-continuous pore structure was previously only predicted mathematically. The desire to realize the structure experimentally inspired the researchers to design surfactants to direct the assembly of silica precursors, which can then be converted into the final silica structures.

|

|

| Fig. 1: Schematic illustration of the tri-continuous network. Each pore channel is represented by a different colored rod. (Reproduced from Ref. 1 © 2009 J. Y. Ying)

|

|

In designing their surfactants, Ying and her co-workers played two opposing effects against each other to tune the curvature of the interfaces. In practice this means that they used a large head group at one end of the surfactant molecule to favor the formation of high-curvature interfaces. On the hydrophobic chain at the opposite end of the molecule, they added a large side group that promotes the formation of low-curvature interfaces. When they combined the surfactant with the silica precursors, they tuned the experimental conditions to favor one effect or the other to produce the desired surface curvature. This fine tuning enabled the creation of tri-continuous networks, but could, in principle, be applied to make even more complex structures in the future, says Ying.

|

|

Bi-continuous network mesoporous silica materials are well known for their tunable pore shapes and connectivity, which make them ideal for catalyst supports because they can be tuned so that the reactants and products flow to and from the catalytic sites. Ying expects that the tri-continuous materials will find similar applications, and that “the tri-continuous nanoporous silica may provide more varied opportunities, which will be revealed by further investigations.” The three-dimensional structure also lends itself well to high-surface-area applications, like electrode materials for batteries and fuel cells.

|

|

In addition, the tri-continuous material can be produced in the form of nanofibers. These offer some ultra-short channels through the pores across their width and some ultra-long channels down the length of the fiber. The researchers say these different diffusion times could be particularly useful for applications in separation and controlled release.

|