| Posted: May 26, 2010 |

Photonic crystal fibers with unique internal cross-sections take chemical detectors to new levels of sensitivity |

|

(Nanowerk News) The thin glass threads of conventional optical fibers underpin our information-driven society, moving data in the form of light pulses at breakneck speeds around the globe. Now, a new type of optical fiber, called photonic crystal fiber (PCF), is set to revolutionize the performance of fiber-optic devices. PCF contains a periodic arrangement of small air holes that can manipulate the behavior of photons, enabling control over the transmission of light in ways never seen before.

|

|

PCF has a number of important uses besides telecommunications, particularly in the field of chemical sensing. By filling the micro-sized cavities of PCF with small amounts of liquid sample, scientists can identify and quantify which molecules are present through evanescent field absorption spectroscopy—a technique that measures how a propagating wave of light interacts with specific chemical structural groups. Because PCF is an extremely efficient light trap, these fibers have the potential to greatly boost signal strength and reduce noise during adsorption experiments.

|

|

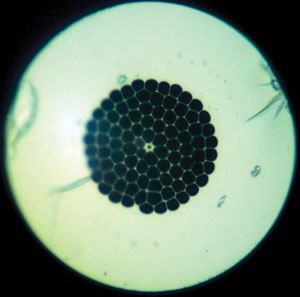

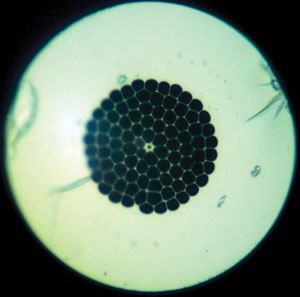

| Fig. 1: Optical microscopy image of a new photonic crystal fiber featuring hexagonal internal microstructures.

|

|

Xia Yu from the Singapore Institute of Manufacturing Technology at A*STAR and her Singapore-based co-workers have now developed a PCF with twice the sensitivity of typical optical absorption instruments, based on an array of hexagonally shaped air holes ("Highly sensitive photonic crystal fiber based absorption spectroscopy "). The small size and highly accurate readings of this new fiber make it suitable for microchip-sized medical devices, such as implantable sensors.

|

|

PCF is typically produced through a technique known as ‘stack-and-draw’, in which silica capillaries are first stacked into an assembly that reproduces the photonic crystal structure on a macroscopic scale; the stack is then fused together with heat and a thin optical fiber is drawn out of the bottom. By carefully controlling the pressure difference between the inside and outside of the capillaries during the fiber drawing process, Yu and her co-workers were able to produce air holes with hexagonal or elliptical microstructures (Fig. 1), instead of the usual circular shapes.

|

|

Absorbance measurements on a cobalt chloride dye solution revealed that the new hexagonal PCF gave accurate readings that were up to six times more sensitive than for PCF containing circular cavities. Yu explains that this enhanced optical behavior occurs because the hexagonal air holes create a bigger localized evanescent light field to interact more closely with the chemical analytes.

|

|

The exceptional properties of this easy-to-fabricate material should lead to a broad range of applications, says Yu. “This type of photonic crystal fiber will be useful for sensors in liquid or gas mediums—which can be extended to water detection, chemical sensing, or bio-sensing.”

|