| Posted: Sep 15, 2010 |

|

Microfabrication: The power of heat

|

|

(Nanowerk News) Most electronic devices use batteries as a power source, but for wireless sensors and medical implants, battery replacement can be a difficult and costly process. Conventional batteries also produce a lot of waste materials and chemicals, so an alternative technology for powering electronic devices is highly sought after.

|

|

Thermoelectric generators, which convert thermal energy into electricity, have been touted as a 'no-fuss' and environmentally friendly alternative to batteries. These devices use heat from the body — or any object with a temperature gradient — as their energy source, and so are free of running costs and have a virtually unlimited lifetime.

|

|

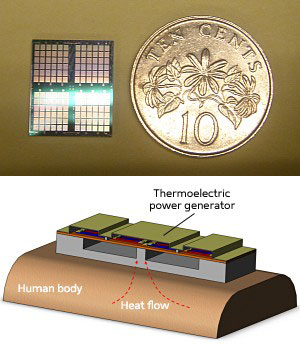

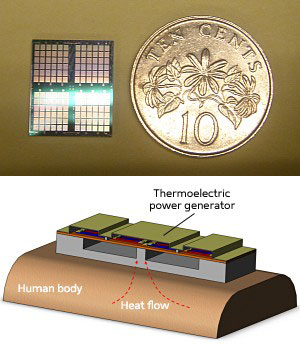

| Fig. 1: A schematic illustration (lower) showing how a CMOS-based thermoelectric power generator could use body heat to generate electricity, and a photograph (upper) of the actual power generator chip.

|

|

At the heart of every thermoelectric generator is an array of thermocouples that are responsible for converting thermal energy into electricity. Bismuth telluride and its alloys are commonly used in thermocouples, but unfortunately, these materials are difficult to produce and work with. The fabrication process is also incompatible with the complementary metal oxide semiconductor (CMOS) architecture on which modern electronics is based.

|

|

Jin Xie and co-workers at the A*STAR Institute of Microelectronics have now constructed a thermoelectric generator based on polysilicon thermocouples using a microfabrication process that is fully CMOS-compatible ("Design, Fabrication, and Characterization of CMOS MEMS-Based Thermoelectric Power Generators"). The researchers were able to fabricate the thermoelectric generator and circuitry on a single chip at the one time and using the same material.

|

|

Xie and his team deposited polysilicon onto a one-centimeter-square chip by a process called chemical vapor deposition. They then dry etched the polysilicon layer and implanted it with phosphorus and boron atoms to produce an array of over 125,000 thermocouples that convert thermal energy into electrical current.

|

|

To maximize the energy-conversion efficiency, the researchers also incorporated three unique features into their thermoelectric generator. First, they sealed the thermocouples between two vacuum cavities to optimize heat flow. Second, they coated the cold side of the device with a heatsink material to disperse heat and maximize the temperature difference, and third, they included a peripheral cavity to isolate heat from the surrounding silicon substrate.

|

|

The new thermoelectric generator is compact and inexpensive to produce. Simulations and experiments showed that a thermoelectric generator experiencing a temperature difference of 5 °C generates a voltage of 16.7 volts at an output power of 1.3 microwatts. This level of energy-conversion efficiency is almost double that for conventional thermoelectric generators.

|

|

"By accumulating this energy over time, the generator can help prolong battery life and recycle waste heat from devices," says Xie. He believes that the technology is particularly suitable for self-powered CMOS devices that have low power consumption requirements.

|