| Nov 30, 2010 |

Materials research with antiparticles: Unravelling the secret of nanocrystalline materials

|

|

(Nanowerk News) Certain structural defects in materials are what make innovative nanocrystalline bulk metals very hard and yet readily malleable. As these defects are found at the atomic level of the metal structure they are difficult to investigate in experiments. However, Austrian scientists have recently taken a significant step towards understanding such atomic defects. They succeeded in doing so by combining two special methods in a project funded by the Austrian Science Fund FWF. The results have now been published in the renowned scientific journal Physical Review Letters ("In Situ Probing of Fast Defect Annealing in Cu and Ni with a High-Intensity Positron Beam").

|

|

Extremely hard but still easily malleable – the properties of the so-called nanocrystalline bulk metals give rise to many questions among physicists. Scientists at Graz University of Technology have finally managed to answer some of those questions through experiments.

|

|

The scientists set out to monitor the structural changes in the metals in real time. They were thus able to conclude that

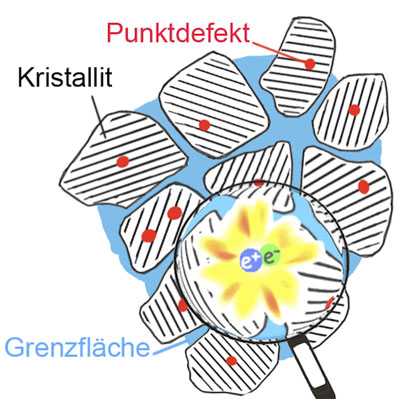

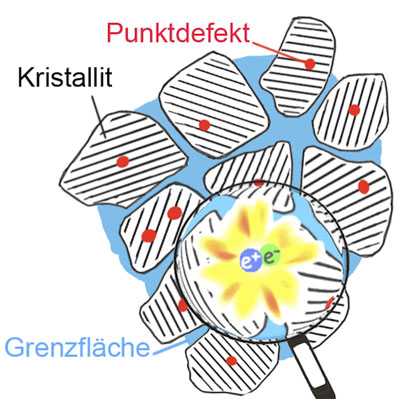

atomic defects are a central cause of the interesting physical material properties. Nanocrystalline metals consist of countless crystallites (grains), which are mostly smaller than one hundred nanometres – and the smaller the grain, the more solid is the metal. The structure of nanocrystalline metals is actually very regular: the atoms in the grains lie tightly packed in rank and file. However, when the metals are produced, atomic defects are involuntarily introduced which disturb the atomic order within the grains. For example, certain layers are not located directly on top of each other: some atoms are missing or rows are misaligned. Austrian materials physicists have now produced the first experimental evidence of these effects, which are closely related to the mechanical properties. They have published their results in the journal Physical Review Letters, where they describe how the combination of two special methods can be used to closely examine atomic defects.

|

|

| Nanocrystalline materials rely on imperfection. Structural defects are responsible for their unusual material properties. (Illustration: Wolfgang Spiegel)

|

|

Spy attacks on metals

|

|

As atomic defects on the nanoscale are difficult to spot, the scientists worked with so-called positrons. Dr. Wolfgang Sprengel from Graz University of Technology explains: "A positron is a subatomic particle that is almost identical to the electron, with one difference: it is positively charged. If a positron and an electron meet, they annihilate each other. In the places where atomic defects are present, there are fewer electrons and therefore fewer occurrences of annihilation. The positrons therefore serve as spies that deliver detailed information about the atomic defects. We have used this effect to analyse the fast processes of atomic defects in metals." To carry out the experiments, the scientists availed themselves of the FRM II research reactor at the Technische Universität München (TUM), where they deployed the positron beam with the highest intensity in the world.

|

|

Two methods, one result

|

|

In addition to the positron-electron annihilation, macroscopic length-change measurements were made upon annihilation of the defects – by means of dilatometry. This combination of dilatometry and positron-electron annihilation is a first of its kind and it delivered the evidence that some of the seemingly mysterious physical properties of the nanocrystalline bulk metals can be attributed to these structural defects. The cause of the defects can be found in the production background of the metals. Nanocrystalline bulk metals are produced using very complex methods – such as high-pressure torsion (Erich Schmidt Institute Leoben) – which give rise to the atomic defects.

|

|

The FWF project headed by Dr. Roland Würschum is carried out in close cooperation with the University of Vienna and the Erich Schmidt Institute in Leoben, and is also closely linked to the National Research Network (NFN) on nanocrystalline bulk metals. The project has enabled a better understanding of fundamental principles, which is essential for the application of these innovative materials.

|