| Jun 16, 2011 |

Pioneering miniaturized e-nose technology

|

|

(Nanowerk News) Imec and Holst Centre are working on a number of gas sensing technologies, relentlessly scaling the sensor, readout electronics and power consumption. The result will be sensors-on-a-chip, used as standalone e-nose (electronic nose), or as nodes in low-power, wireless sensor networks.

|

|

The following are two recent developments. The first is a novel gas sensor for nitrogen oxides that is extremely sensitive and that has been designed with cost-effective mass production in mind. The second development concerns the read-out electronics for a sensor array, a chip that will be capable of identifying thousands of molecules from vapors.

|

|

1. Innovative gas sensor paves way for personal air quality monitors

|

|

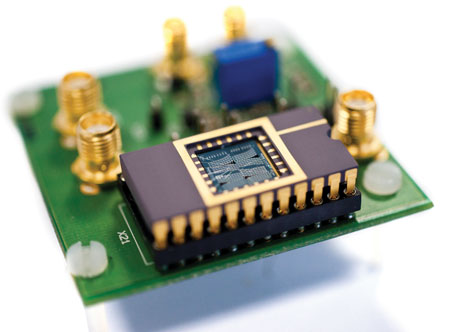

Imec and Holst Centre have demonstrated the word's first small, low-power gas sensor capable of detecting nitrogen oxides (NOx) at the parts per billion (ppb) level. Fully scalable to industrial, high-volume production, the new sensor could lead to personal, wearable air quality monitoring applications.

|

|

NOx gases such as nitrogen monoxide (NO) and nitrogen dioxide (NO2) are common air pollutants and key precursors for a range of secondary pollutants. They are naturally present in air at the tens of ppb level, but can cause breathing and health problems at concentrations above 100ppb. Previously, detecting NOx in this range was only possible with large, high-power devices – restricting air quality monitoring to tabletop, mains-powered applications.

|

|

Imec and Holst Centre have now demonstrated a new sensor concept that delivers the same accuracy in sensors just microns across. The sensor is based on layers of aluminum gallium nitride (AlGaN) and gallium nitride (GaN) grown on silicon substrates. A two-dimensional electron gas (2DEG) is formed at the interface between these layers, and provides a highly conductive channel sensitive to changes at the sensor's surface. Moreover, because the channel is buried below the surface, noise in the channel is extremely low. Consequently, the new sensor is much more sensitive than previous technologies.

|

|

In a world first, the sensor has been demonstrated in a battery-powered application with a wireless module. Further development could push the sensitivity down to the parts per trillion (ppt) level, which would be useful for applications such as asthma monitoring. Imec and Holst Centre are also looking to extend the sensor's functionality to detecting other gases at equally low concentrations.

|

|

| Imec and Holst Centre's integrated NOx sensor.

|

|

2. Demonstrator e-nose with novel read-out mechanism

|

|

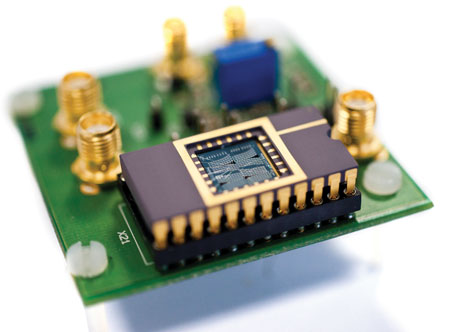

Imec and Holst Centre have made a further step in the development of their e-nose for complex vapor mixtures. The current development concerns a low-power read-out mechanism for the e-nose sensor elements, which were previously developed (http://www2.imec.be/be_en/press/imec-news/archive-2010/gassensor.html). The goal is to make a miniature customizable low-power sensor for the identification of hundreds to thousands of molecules in vapor mixtures. Such a sensor could be used in applications ranging from healthcare and safety to food monitoring.

|

|

The heart of the e-nose sensor is an array of microbridges, micromechanical resonators that vibrate at specific resonance modes. These bridges can be coated to make them sensitive for the presence of a particular molecule. When such molecules attach to a bridge, its resonance modes change, which can be detected. In a previous development, imec and Holst Centre made the technology for high-density arrays of such suspended beams with integrated piezoelectric transducers that can be individually coated with varying coating chemistries (see http://www2.imec.be/be_en/press/imec-news/archive-2010/gassensor.html).

|

|

Recently, we also demonstrated oscillator-based read-out electronics for the sensor array. We connected a sensor beam in a positive feedback loop to a sustaining amplifier, with an automatic gain control for improving the performance. This demonstrator was implemented with standard off-the-shelf components. As a proof-of-principle, ethanol and water vapors were blown on the sensor and the resonance frequency of the loop was investigated. We measured a clear frequency shift, as well as volatile-specific sensor recovery times. In parallel, we are demonstrating and characterizing a low-power ASIC with integrated microbridges and electronics.

|

|

| E-nose with readout electronics, used for ethanol and humidity detection.

|

|

Results of the e-nose project have proved very successful, and upcoming effort will focus on a range of multidisciplinary topics. A first topic will be to work on the target selectivity for various gas compounds in multi-array sensing. Second, for the readout of dense-arrayed sensors, we work on advanced, multiplexed ASIC design. Third, a flawless integration of dense-arrayed sensors with the ASIC needs to be addressed. Last but certainly not least, the integration of the multi-sensor system with low-power wireless technology will be explored.

|