| Aug 22, 2011 |

Summer students present first results on 'nanoscale origami'

|

|

(Nanowerk News) This summer, imec welcomed 4 students from John Hopkins University (JHU), a world-class university in Baltimore, US, for a research internship of 10 weeks in the field of bioelectronics. These internships coincide with the announcement of a scientific story on nanoscale origami that has resulted from the internship of the first JHU visiting student in the summer of 2009 with a follow-on program last year. In this work, an approach is presented that allows generating precisely patterned polyhedral nanostructures, envisaged for optical and biosensing applications.

|

|

JHU-imec exchange project

|

|

The students – both graduate and undergraduate – learn to design, fabricate and test a wide range of biomedical devices at imec. One of the internships is part of a collaboration that is ongoing for two years. In January 2012, the first student from imec will have the unique opportunity to work with researchers from the Institute for Nanobiotechnology at John Hopkins University. The overall exchange project is enabled by the International Research Experience for Students (IRES) program, which is funded by the National Science Foundation. These internships are very valuable as they contribute to the learning experience of the students and enrich the research activities of both imec and JHU. Besides this project, imec has an agreement with Olin College, US, to exchange students for intensive internships at imec or Olin, and has plans to extend its collaboration with other top universities and institutes in the US.

|

|

In addition, we present a scientific story on 'nanoscale origami' that has resulted from the internship of the first JHU visiting student, Michael Keung, who worked at imec in 2009 and 2010. The work has been published in a special issue of the journal Small, vol. 7, n°14, July 2011, and an image from the paper was selected as the inside cover image. The paper results from collaboration between imec and David Gracias' group at John Hopkins University. Michael Keung has since completed his M.S. in Engineering.

|

|

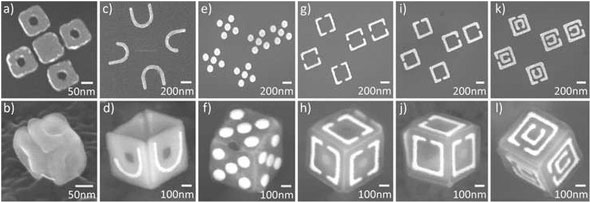

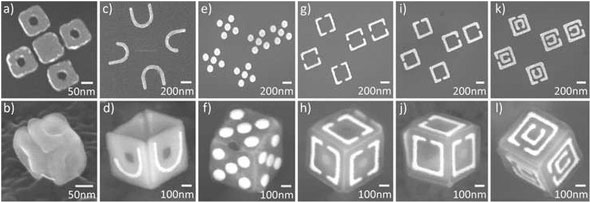

| Scanning electron microscopy (SEM) images of the patterns (a-hollow squares; c-alphabet; d-dice-like; e-f-g-SSRs) and folded cubes.

|

|

'Nanoscale origami' enables the creation of 3D nanostructured devices for optics and biosensing

An origami-inspired approach is presented that allows generating precisely patterned polyhedral nanostructures. The method is based on the nanoscale self-folding of samples that have been patterned using electron-beam (e-beam) lithography. The nanoscale origami approach can greatly augment the capabilities of miniaturized optical devices and can be used for applications in biosensing. The technique has been demonstrated by the creation of structures with optically active split-ring resonator (SRR) patterns.

|

|

The novel approach allows precisely patterning optical or electronic elements in two dimensions and subsequently folding them up into three dimensions – just like the ancient Japanese art of paper folding. Transforming 2D patterns into 3D patterns presents a major advantage as compared to existing 3D nanostructures which have only very limited surface patterns. The method allows the creation of various polyhedral nanostructures with a versatility in the types of patterns, and are envisaged for optical and biosensing applications.

|

|

The overall process flow consists of first patterning in 2D the optically or electronically relevant features by using e-beam lithography and lift-off processes. After patterning, subsequent steps of e-beam lithography are used to define panels and hinges. Next, the structures are released from the substrate by using plasma etching of the underlying Si substrate. During etching, the heat generated by the exothermic etching process causes grain coalescence or reflow of the hinges. The hinges act as self-folds by generating a torque to rotate panels and create the 3D nanostructures. The fold angle can be controlled by tuning the plasma processing conditions. Sn was used as the hinge material and either Ni or Al2O3 was used as the panel material.

|

|

With this technique, geometric shapes, alphabets and three types of SRRs (with cube sizes 100nm and 500nm) have been patterned within a single Au layer. Patterns of Au SRRs are especially relevant for 3D optics. Reflection spectra of a folded nanocube with a single SRR patterned on each of the six faces was successfully collected by using infrared excitation. The expected polarization dependence is clearly observed. The researchers demonstrated another interesting functionality that consists in generating a unique plasmonic barcode on all faces. This allows seeing the orientation of the cube by optical probing and can be used as an optical gyroscope with plenty of opportunities for bioresearch. In the future, further experimentation is required to extend the nanoscale origami approach to other material combinations.

|