| Aug 29, 2011 |

Gallium nitride-based diode generates particles that are a hybrid of light and matter

|

|

(Nanowerk News) Half-matter, half-light quasiparticles known as polaritons could one day be used to create high-efficiency, high-speed light-emitting devices. Polaritons are created by enhancing the interaction between light and matter in way that binds them together, a process that is commonly achieved by trapping photons in a cavity and concentrating the optical energy into a volume smaller than a micrometer across. The easiest way to then kick-start polariton generation is to fire laser light into the cavity. However, if these exotic particles are to be harnessed in self-contained devices, there is a need to create polaritons using an electrical current rather than laser light.

|

|

Tien-Chang Lu and colleagues from the National Chiao Tung University in Taiwan and Stanford University in the US have now developed an electrically injected device that creates polaritons in the semiconducting material gallium nitride ("Room Temperature Current Injection Polariton Light Emitting Diode with a Hybrid Microcavity"). The new device is tiny and provides a simple way of creating polaritons at up to room temperature.

|

|

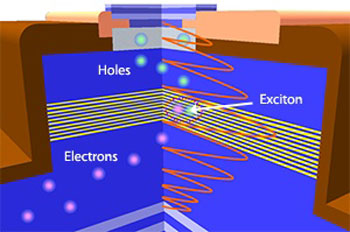

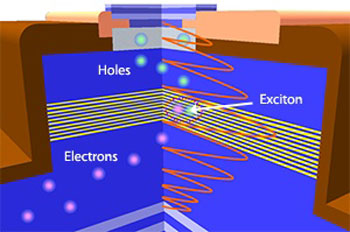

| Schematic illustration of a hybrid optical cavity for efficient generation of excition-polaritons. (© 2011 ACS)

|

|

Polariton light-emitting diodes (LEDs) have been created before using materials such as gallium arsenide and organic semiconductors. The advantage of gallium nitride, however, is that electrons and their positive-charge equivalent called 'holes' that form the matter part of the polariton are bound together much more strongly. "Materials such as gallium nitride with a larger binding energy provide more reliable room-temperature operation and numerous other properties that make them better suited for polariton devices."

|

|

The main challenge for Lu and his team was creating a gallium nitride optical cavity that trapped photons efficiently. The mirrors at each end of their cavity were constructed from thin alternating layers of gallium nitride and aluminium nitride for the bottom mirror, and tantalum pentoxide and silicon dioxide for the top (see image). "This hybrid structure with both a semiconductor and a dielectric mirror reduced fabrication complexity and allowed us to produce a high-quality microcavity," explains Lu. "In comparison with the standard LED, the polariton LED has the advantages of enhanced out-coupling efficiency, high directionality with narrow emission pattern, and faster response time," he says. "In the near future we hope to extend this design and develop a current-injection polariton laser diode."

|