| Oct 11, 2011 |

Stamping out nanodots

|

|

(Nanowerk News) With the rapid expansion in nanotechnology and its applications, there is a need for increasingly accurate production methods for nanoscale parts. Arrays of metal nanodots on a surface, for example, can be used as components in data storage, sensors and solar panels. However, production of the well-defined metal nanodots of less than 100 nm in size needed for the most advanced nanotechnology applications remains a challenge.

|

|

Won Bae Kim and colleagues from the Gwangju Institute of Science and Technology in Korea have now developed a stamping technique for producing metal nanodot arrays that could potentially be used for large-scale manufacturing ("Printing of sub-100-nm metal nanodot arrays by carbon nanopost stamps").

|

|

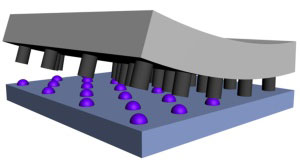

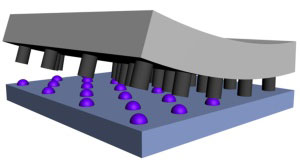

| A schematic illustration of a stamp constructed from carbon nanoposts for the production of arrays of metal nanodots.

|

|

The researchers' stamping process involves an array of vertical nanoposts, structures that have previously been used to create molds in nanolithography, nanosyringes for cell delivery, and electrodes for lithium-ion energy storage. "We were inspired by the possibilities of the sub-100 nm nanoposts," says Kim, "and expected that these architectures could be used as a versatile way of constructing a stamping platform."

|

|

In the stamping system developed by Kim and his team, carbon nanoposts are positioned vertically in a hexagonal crystal lattice of aluminum oxide, with full control over the positioning and pattern produced by each stamp. "We devoted a lot of effort to determining how the etching conditions could be modified to tune the length of the nanoposts," says Kim.

|

|

Each nanopost is coated with silane-based molecules as a releasing agent, a layer of the desired metal for the dot array, and finally a layer of titanium. The coated nanopost platform is then turned upside down and the metal dots are stamped onto a substrate (see image). The titanium layer acts as the 'glue' that attaches the metal dot to the substrate surface, and the release agent ensures that the metal dots are reliably unstuck from the stamp.

|

|

Nanodot arrays of many different metals can be produced using this method. Gold nanodot arrays, for example, can be used to enhance reflectivity in optical devices, while silver nanodots have excellent electrical and thermal conductivity, platinum nanodots could act as catalysts in fuel cells, and aluminum nanodots could be used for semiconductor nanowire growth.

|