| Nov 21, 2011 |

Thermoelectrics: Roughing it

|

|

(Nanowerk News) Thermoelectric materials convert a temperature gradient into a voltage. Most thermoelectrics, however, are too inefficient for widespread practical application. Still, the possibility that these materials could usefully harness heat waste, such as that generated by combustion engines, makes improving their efficiency an important pursuit in materials science. A team of scientists led by Wooyoung Lee at Yonsei University in Korea has now shown that interface roughening may be an effective way to enhance the thermoelectric properties of core/shell nanowires ("Reduction of Lattice Thermal Conductivity in Single Bi-Te Core/Shell Nanowires with Rough Interface").

|

|

In the ideal thermoelectric, the charge conducts easily from a hot point to a cold one, while heat conduction is low. The ratio between these quantities is contained in the thermoelectric 'figure of merit'.

|

|

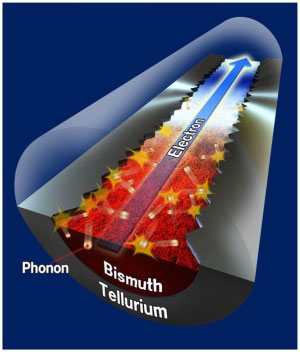

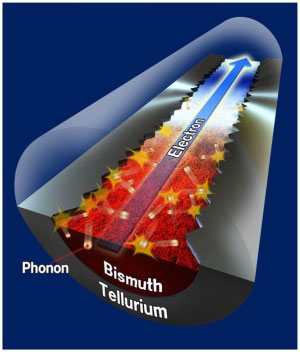

| Nanowires with a bismuth core encased in a tellurium shell have improved thermoelectric properties when the interface between the core and shell is roughened by impeding the flow of phonons, but not electrons.

|

|

As both electrons and vibrational waves in the lattice, known as phonons, contribute to a material's thermal conductivity, Lee and his colleagues attempted to raise a material's thermoelectric figure of merit by suppressing the conductivity of phonons without impairing electrical conductivity. This can be achieved by adding defects or nanostructuring a material to make it smaller than the phonon mean-free path — the typical distance a phonon travels before it scatters.

|

|

Lee and his team combined both of these tricks to reduce the thermal conductivity of a promising thermoelectric material consisting of a bismuth nanowire core coated with a tellurium shell. The team synthesized the wires by cooling just-prepared bismuth nanowires with liquid nitrogen and then coating them with tellurium using a sputtering technique, giving a core/shell structure with a smooth interface. They also prepared the wires without the cooling step, resulting in a rough interface.

|

|

After examining a series of the core/shell nanowires of 160–460 nm in diameter in both the smooth and rough versions, the researchers noticed two trends: the narrowest wires had the lowest thermal conductivity, and wires with rough interfaces had lower thermal conductivity than those with smooth interfaces — in some cases by as much as a factor of five.

|

|

According to Lee, roughening of the interface between the bismuth and tellurium reduces the thermal conductivity of phonons more significantly than electron thermal conductivity (see image). "The overall effect is to increase the thermoelectric figure of merit," says Lee.

|