| Nov 21, 2011 |

Microfabricated polymers thrive under pressure

|

|

(Nanowerk News) The lithography-based fabrication of semiconductor circuits relies heavily on the photo-induced polymerization and cleavage of bonds within thin organic films. Yet as circuit sizes shrink below the wavelength of light used for patterning, researchers find it increasingly difficult to control these photo-initiated processes. Now, Syoji Ito and co-workers from Osaka University and other institutions in Japan have developed a new way to fabricate nanoscale polymer structures with extreme spatial accuracy using the radiation pressure of a focused near-infrared (NIR) laser beam ("Confinement of Photopolymerization and Solidification with Radiation Pressure").

|

|

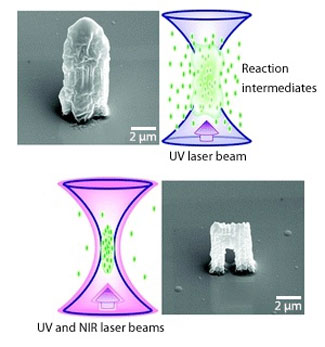

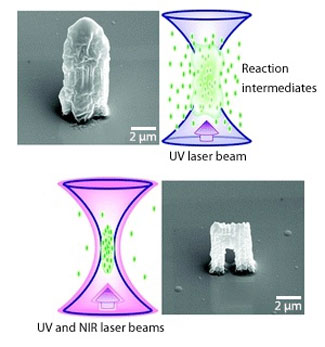

| Scanning electron microscopy images of shapes formed by polymerization under ultraviolet (upper) and ultraviolet and near-infrared (lower) laser irradiation. (© 2011 ACS)

|

|

As photons of light have momentum as well as energy, they can exert a mechanical force known as radiation pressure on other objects. The radiation pressure from a laser beam, for example, can be used to manipulate small objects — a technique used in DNA engineering and nanotechnology. This technique is also used in chemistry, where it allows polymers to be rearranged into new microstructures, such as linking chains to form spheres.

|

|

Controlling polymerization reactions using radiation pressure, however, has seemed impractical because the mechanical force is usually too weak to affect individual molecules. It is also difficult to monitor the chemical processes taking place inside optical tweezers due to interference from the laser beams.

|

|

Ito and his colleagues used a differential approach to show that it is possible to confine polymerization into nanoscale 'reaction cages' defined by laser light. The team first dabbed a liquid solution of an acrylic resin onto a glass slide, and then initiated a photo-polymerization reaction by exposing the resin to an ultraviolet laser. The researchers then repeated the same experiment in the presence of a radiation pressure-emitting NIR laser. Scanning electron microscopy images clearly showed that the combination of ultraviolet and NIR beams enhanced the production of polymer microdots due to optical trapping effects.

|

|

By constructing a three-dimensional laser scanning apparatus, the researchers were able to synthesize well-defined acrylic polymer microstructures with dimensions 80% smaller than the NIR laser light wavelength using this innovative technique. "Our results provide a new avenue to control chemical reactivity using the force of light," says Ito. "This is a frontier of interdisciplinary research with many possible applications, from three-dimensional nanocircuits to photonic crystals."

|