| Mar 15, 2012 |

Microlens arrays from the test tube

|

|

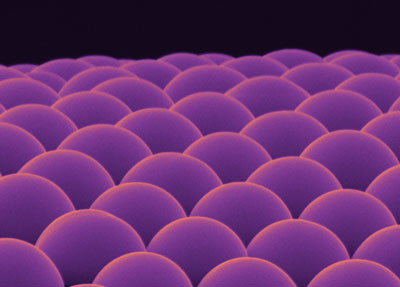

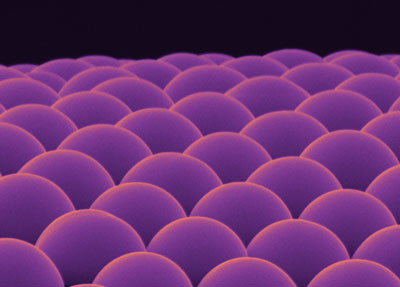

(Nanowerk News) Biomineralized tissues, such as sea shells and bones, grow in a genetically programmed way to obtain specific shapes and compositions, which define the unique functionalities. The growth of biominerals usually takes place in aqueous media at ambient conditions. Material scientists are keen to adapt this process from nature for a cost-efficient and simple fabrication of inorganic based materials. The research team has discovered that micrometer-sized CaCO3 structures are formed at the surface of Ca saturated solution in a few minutes in atmospheric condition, which grows further to form a thin film in 1-2 hours. Simply by adding organic surfactants, the researchers were able to synthesize the structures with hemispherical shape and uniform size (see paper in Nature Communications: "Self-assembly of amorphous calcium carbonate microlens arrays").

|

|

"This is such a simple and cheap process for the fabrication of high quality microlens arrays and you just need Ca saturated solution with a small amount of the organic surfactant, while alternative lithographic techniques require multiple steps and a clean room." explains Kyubock Lee, a researcher who worked on the project at the Max Planck Institute of Colloids and Interfaces in Potsdam and at the KAIST in South Korea.

|

|

| Microlens arrays made from calcium carbonate. (©Kyubock Lee / MPI of Colloids and Interfaces)

|

|

Biocompatible micro-optical device

|

|

The researchers could observe clear multiple image of a micron-sized 'A' projected through the array of microlenses.

|

|

"It was very surprising when we observed that hemispherical CaCO3 structures work as micron-sized convex lenses with such a high quality. These optical properties have not been demonstrated before with synthetic CaCO3 structures." says Wolfgang Wagermaier, research group leader in the Biomaterials Department at the Max Planck Institute of Colloids and Interfaces.

|

|

The collimated light could be focused into a spot of 1 micrometer by passing through CaCO3 microlenses with 6 micrometers in diameter and a focal length of 7 to 8 micrometers. CaCO3 is well known to be a biocompatible material which many biological organisms are using as base material for their skeletons. The researchers showed the biocompatibility of the CaCO3 microlens arrays by seeding fibroblasts which are the most common cells of connective tissue in animals. This proved the viability of the cells on the array. A single cell covers several tens of microlenses. This shows the potential of using CaCO3 microlens arrays for cell biology research combined with optics or for light actuation systems at the micron-scale.

|

|

CaCO3 microlens array in nature and biomimetics

|

|

Indeed, there are living organisms which employ CaCO3 microlens arrays as optical devices. Especially the brittle star Ophiocoma wendtii, for example, is able to respond to light effectively by focusing incident light rays on a photoreception system through its skeleton which consists of calcite microlenses. It is very amazing that nature is able to form such a perfect optical device with an optical aberration-free shape together with a birefringent-free crystal orientation.

|

|

This functional skeleton of the brittle star as well as other biological materials grow by principles of self-assembly, which allows in general the adaptation and optimization of materials.

|

|

Peter Fratzl, head of the Biomaterials Department at the Max Planck Institute of Colloids and Interfaces, says: "Usually it is very challenging to fully understand and mimic the biologically controlled formation of such advanced mineral structures, although it is an eventual goal of biomimetic materials research. However, the fabrication of CaCO3 microlens arrays demonstrates that the principles of self-assembly and organic controlled formation of mineral could be realized to produce advanced optical devices."

|

|

|