| Mar 27, 2012 |

International researchers discuss how the mechanics of materials changes with size

|

|

(Nanowerk News) An electric cable can also be installed around edges and corners in houses due to the metal structure in little: The wires consist of copper grains, which can be deformed. Thus, the wire remains intact even when bent. Only when the copper grains are smaller than one thousandth of a millimeter, the properties change and therefore the metal's behavior: It becomes harder and breaks faster. During the international workshop Nanobrücken II at INM – Leibniz Institute for New Materials on 22 and 23 March 2012, materials researchers from Europe discussed why such mechanical properties of a material change in smallest dimensions.

|

|

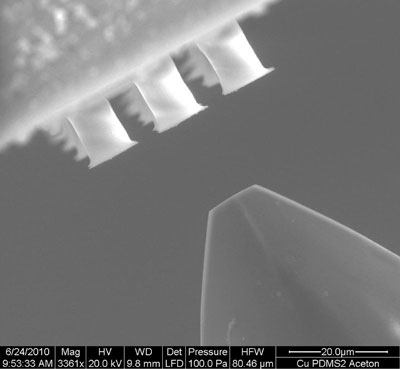

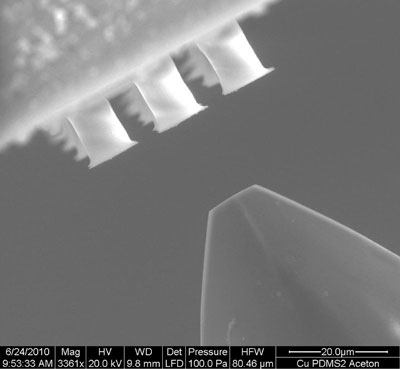

| PDMS Pillars with Nanoindenter

|

|

"We know that materials in size ranges under one thousandth of a millimeter behave mechanically in a different way from larger units", says Roland Bennewitz, head of the program division "Nanotribology". "It is not completely understood yet, why and how materials change their properties in smaller units. If our measurements allow us to explain the determining factors behind it, we will be able to tailor the mechanical behavior of materials in the future", explained the physicist. A certain hardness, viscosity, deformability and even combinations of these properties could then be precisely tailored. New concepts for hardened metal surfaces or sliding rubber seals are imaginable in the future.

|

|

In order to understand the phenomena behind it, the researchers use special analytical methods. The so-called nanoindenter has a sharp tip, which is pressed into the surface of a material sample, examining its deformability. At INM, the researchers are able to produce samples with microscopic dimensions. By the so-called "ion-etching" very small pillars with different diameters are produced, which are scanned by a sharp tip.

|

|

Important parameters are the tip's depth of indentation, the energy needed, or the way the pillars are crushed during the scanning. The whole process is done in a dimension of only a few millionths of millimeters. "For the measurements, we use a special nanoindenter developed by Hysitron, whose measuring possibilities were tailored especially to our needs", the materials expert explains. Usually, hard probes, i.e. metals, ceramic or even nacre, can be examined with such equipment. But it is no problem to also examine smooth probes, such as plastics, with the specially developed equipment.

|

|

For the scientific discussions, INM invited international researchers with their special knowhow. 60 researchers from Europe took part in the two-day congress Nanobruecken II. Nanobruecken is taking place at INM for the second time. In workshops, the company Hysitron presents technical innovations of their nanoindenters.

|

|

|