| Posted: January 9, 2008 |

Make nanoparticles while the sun shines |

|

(Nanowerk News) Concentrated sunlight is all you need to make useful nanomaterials, according to Israeli researchers.

|

|

|

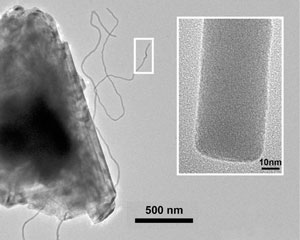

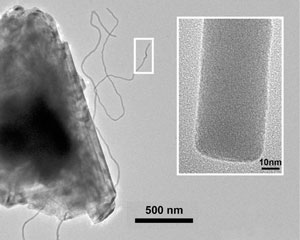

Jeffrey Gordon of Ben-Gurion University in the Negev desert, Reshef Tenne of the Weizmann Institute, Rehovot, and their collaborators collect solar radiation outdoors and transmit it to an indoor laboratory with optical fibres. Here it is focussed on molybdenum sulfide or quartz powders, transforming them into nanotubes and nanocages. This is the first time that silica nanofibres and nanospheres have been produced from pure quartz, they said.

|

|

Wolfgang Tremel, who works on inorganic nanoparticles at the University of Mainz in Germany explained 'A particular problem in the synthesis of fullerene-type nanoparticles and nanotubes is that high temperatures are needed to interconnect the edges of fragments in such a way as to provide curvature to otherwise flat slabs.'

|

|

Gordon and Tenne believe that the solar route is far less energy intensive than laser ablation or high-temperature chemical reactors, simpler and less costly, with only an 'uncomplicated optical system' required to deliver the light to the reaction vessel.

|

|

There are plenty of refinements that can be made: 'We need to find optical and reactor configurations that ensure nanotube and nanoparticle generation in a more uniform and reproducible fashion,' said the researchers. And, they add, it opens up new mechanistic questions: 'Does photochemistry play a role or are the only important factors the temperature and flux gradients?'

|

|

Tremel warned that in its current state the technique will be unable to 'yield samples at the gram scale'. More importantly though, he said that it promises new sorts of fullerene-like nanoparticles. These conditions, he said, 'enable the formation and trapping of nanoparticles from metal oxide compounds which, like quartz, have significantly lower vapour pressures than metal chalcogenides'.

|