| Posted: February 9, 2008 |

Nano-thermal analysis for polymer characterization |

|

(Nanowerk News) For many years, the polymer industry has used thermal analysis measurements to characterize bulk material properties. However, now it has been proved that making localized thermal measurements on much smaller size scales reveals a lot more about how individual components behave at the domain level in terms of properties such as amorphous versus crystalline phases or the distribution of an active component in a heterogeneous mixture.

|

|

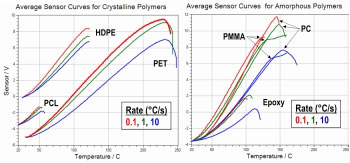

| Example of polymer analysis data using nanoTA (Image: Drs Greg Meyers and Andrew Pastzor).

|

|

In 2006, Anasys launched the nano-TA module to enable users of scanning probe microscopes perform localized thermal analysis. More recently, the stand-alone VESTA system has enabled point-and-click localized thermal analysis measurements without the need for expertise and high investment in a SPM system. With specially fabricated silicon probes, these tools are able to locally heat very small areas of a sample surface and measure thermomechanical signals by monitoring the deflection of the probe. This produces the accurate measurement of thermal events such as the glass transition or the melting point of materials at a resolution of less than 100nm.

|

|

Two examples of the utility of nanoscale thermal measurements have been published as applications papers available free for downloading from the Anasys web site.

|

|

Dow Chemical researchers Drs Greg Meyers and Andrew Pastzor have reported their work that shows correlation between nanoscale and bulk thermal analysis studies. It verifies the capability of the nano-thermal technique to obtain accurate, relevant thermal analysis information while also allowing analysis of localized areas on the sample or very small quantities of material. This greatly extends the utility of thermal analysis to polymer blends, composites and surface properties of materials.

|

|

At Eastman Chemical, Dr Louis T. Germinario has applied nanoscale thermal analysis to the study of automotive coatings. Nano-thermal analysis in combination with AFM proves to be a very valuable tool for the study of polymeric coatings and surfaces in general, since it allows not only imaging but also direct identification and characterization of the different domains at the sample surface on a 100 nm scale. The data clearly demonstrate that nano-TA is more sensitive to surface effects than modulated differential scanning calorimetry which is a measure of the sample averaged or bulk property and hence cannot detect the surface chemical and structural degradation suffered by coatings.

|

|

With a rapidly growing user base in both industry and academia, it is clear that more groups are adopting nano-TA for routine use in both materials characterization and research laboratories.To review these applications notes and other publications from Anasys, visit www.anasysinstruments.com.

|