| Posted: May 28, 2008 |

Nanotechnology process produces plastics that are 10 times more stretchable |

|

(Nanowerk News) Move over, Rumplestiltskin. Researchers in China report the first successful “electrospinning” of a type of plastic widely used in automobiles and electronics. The high-tech process, which uses an electric charge to turn polymers into thin fibers in the presence of electricity, produced plastic mats that can stretch 10 times more without breaking than the original material and could lead to new uses for the plastic, they say. Their study is scheduled for the June 10 issue of ACS’ Macromolecules, a bi-weekly journal.

|

|

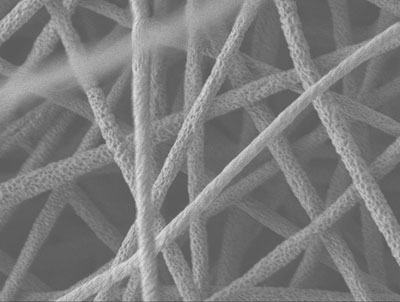

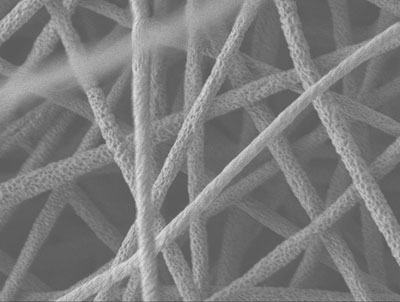

| Micrograph of the electrospun nano-sized fibers (Image: ACS)

|

|

In the new study, Zhao-Xia Guo and colleagues point out that the original plastic, called polyoxymethylene (POM), is an engineering staple known for its metal-like hardness, light weight, and resistance to chemicals. However, the material is relatively brittle, limiting its applications. Although many different types of plastics have been electrospun into fibers with extended uses and properties, researchers have been unable to spin POM into fibers until now, the researchers say.

|

|

They report that POM could be turned into nano-sized fibers — thousands of times thinner than the width of a single hair — after first dissolving it in a solution called HFIP and then undergoing electrospinning. The process resulted in POM mats with improved stretchability, or ductility, high porosity, and high surface area. Such features could extend the plastic’s uses to a wide range of industrial, electronic and medical applications, the researchers say.

|