| Posted: July 20, 2006 |

Add nanotubes and stir - with the right force |

|

(Nanowerk News) Polymer scientists at the National Institute of Standards and Technology (NIST) have some stirring results to share with researchers and companies developing new, advanced composite materials with carbon nanotubes—mix carefully.

|

|

In a paper for Physical Review Letters ("Nonequilibrium phase diagram of sticky nanotube suspensions"), they explain how the amount of force applied while mixing carbon nanotube suspensions influences the way the tiny cylinders ultimately disperse and orient themselves. In turn, the final arrangement of the nanotubes largely dictates the properties of the resultant materials.

|

|

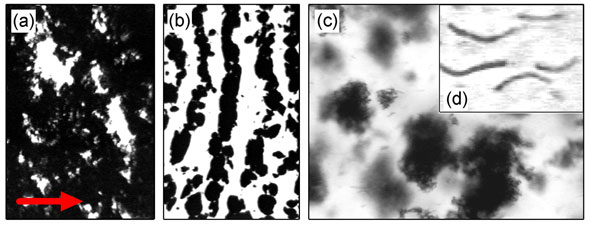

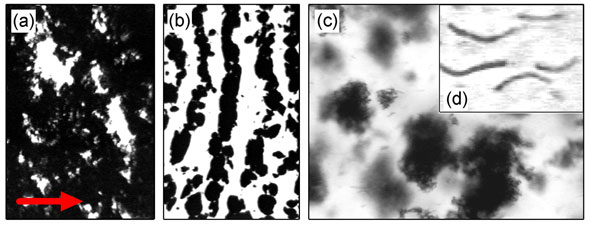

| NIST researchers have mapped the relationship between stirring force and nanotube arrangement, an advance key to the processing of new nanocomposite materials. Images show the evolution from solid-like nanotube networks (a) to macroscopically shear banded fluids (b) to small isolated nanotube aggregates (c) to individually dispersed and aligned carbon nanotubes (d). (Source: NIST)

|

|

Measuring only a few nanometers in diameter (the width of a handful of atoms), carbon nanotubes possess many superior properties that make them highly desirable additives in composites, a class of engineered materials made by blending polymers and fibers or by combining other types of unlike materials. Mixed in polymeric materials, carbon nanotubes can provide incredible strength, toughness and electrical conductivity. The trouble is, nanotubes stick to each other and form networks that tend to stay fixed in place. Apply enough force, the networks will flow but usually end up in tangled clumps. The resultant nanocomposites are difficult to mold or shape, and their properties fall short of expectations.

|

|

In an elegantly simple result, NIST researchers Erik Hobbie and Dan Fry found that networks of carbon nanotubes respond predictably to externally applied force. The networks also showed behavior reminiscent of more conventional materials that align spontaneously under the forces of Brownian motion—the random motion of particles in a fluid famously described mathematically by Einstein.

|

|

The response was so predictable that the scientists mapped out the relationship in the form of a phase diagram, the materials science equivalent of a recipe. Using their “phase diagram of sticky nanotube suspensions,” other researchers can estimate the order that will result when applying a certain amount of force when mixing a polymer fluid with a particular concentration of nanotubes. The recipe can be used to prevent entanglement and to help achieve the nanotube arrangement and orientation associated with a desired set of properties.

|