| Posted: September 9, 2008 |

Nanotechnology images - thrilling and unsual insights |

|

(Nanowerk News) Thrilling and unsual insights. BASF Research has posted images on its website that allow the viewer to explore structures that would otherwise only be seen by analytical chemists. State-of-the-art technologies such as scanning electron microscopy and transmission electron microscopy help to create a genuinely different view of the world and are only now revealing a hidden domain of fascinating forms and structures.

|

|

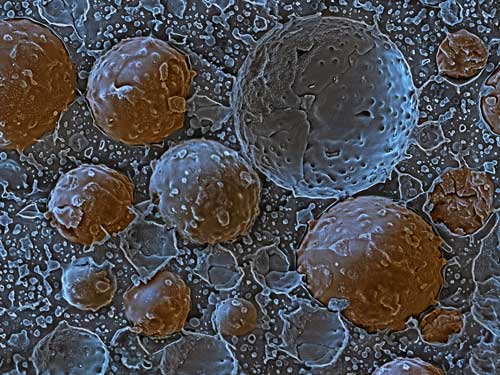

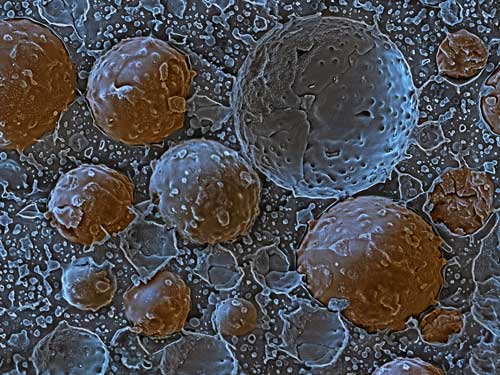

The first image, for instance, what looks like the intricate makings of a futuristic sculptor is the product of nature itself. The spherical spores of the fungal mold Emericella nidulans are coated by a thin layer of hydrophobin, a water-repellent protein that causes rainwater to run off the skin of the fungus leaving no trace. Recognizing the potential benefit of this fungal mechanism for technological applications, BASF scientists became interested in hydrophobin. BASF is now the first company in the world to succeed in synthesizing the protein on an industrial scale.

|

|

"It's a protein with unique properties. It forms very thin films on any kind of surface and thus changes the properties of that surface. For example, glass with a hydrophobin coating will repel water, while Teflon® with a hydrophobin coating will attract water. A coating with this protein is also resistant to temperature, acids and alkalis," says Dr. Claus Bollschweiler, head of the BASF Performance Proteins research group. Scientists are also looking into ways of using hydrophobin-coated polymer sponges to remove diesel and oil from contaminated waters. The protein's broad range of properties makes it suitable for an array of applications. It stabilizes pigment dispersions and has potential as a cosmetic ingredient stabilizing creams and other emulsions. Best of all: once the protein has done its job, it biodegrades in a natural way.

|

|

The following microscopic images are part of the "Images from the World of Research" series, now offering twelve new images from BASF’s cutting-edge research. The series gives an insight into a microcosm invisible to the naked eye – the nanotechnology domain of atoms and molecules.

|

|

| Proteins for surfaces. The spherical spores produced by the fungus Emericella nidulans are coated in a thin layer of the protein hydrophobin. Hydrophobin ensures that water rolls off the spores. Other fungi, such as mushrooms, also have a layer of hydrophobin on their caps. BASF researchers have succeeded in transferring the gene responsible for hydrophobin production to Escherichia coli bacteria. With the help of the bacteria, hydrophobin can be produced as a so-called performance protein on a large scale. Hydrophobin has versatile properties. It can change surfaces to such a degree that they become water resistant.

|

|

|

|

| Zinc oxide particles protect against sunburn. Z-COTE® is a special zinc oxide which, used in sun creams, offers protection against sunburn. The nanopowder is used as a broadband filter against harmful UVA and UVB radiation. The fine zinc oxide particles in Z-COTE act as inorganic UV filters by reflecting the incident UV light like tiny mirrors. Since conventional zinc oxide pigments are white, they can produce an undesired whitening effect on the skin. This is prevented by reducing the size of the pigment particles to about 200 nanometers which makes them transparent.

|

|

|

|

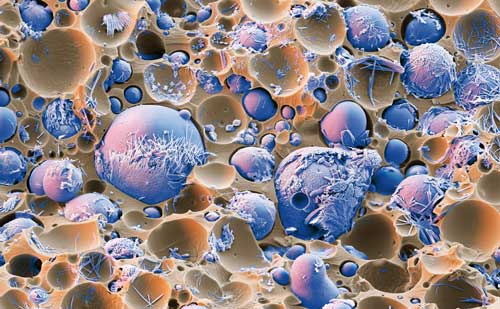

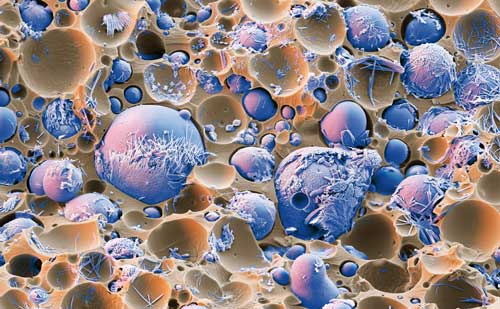

| Pickering emulsions: dispersing water insoluble substances in water. An emulsion is a mixture of two liquids such as water and oil. One liquid is present in the form of droplets and is dispersed in the other liquid. Depending on which liquid is in droplet form, we speak of an oil-in-water or a water-in-oil emulsion. Emulsifiers and surfactants are important components of emulsions, as they promote the formation of droplets and thereby stabilize the mixture. But certain solids can also be added to stabilize an emulsion, that is, to prevent it from separating out into two different liquids. These solid-stabilized and thus surfactant-free emulsions are called Pickering emulsions. They are named after their discoverer S.U. Pickering and can be seen in this picture. With this technique, a hydrophobic – in other words, not miscible with water – active agent is enclosed in micrometer sized oil droplets. These are stabilized by nanometer sized particles made of a biodegradable polymer. Systems like this are suitable for introducing hydrophobic agents such as agrochemicals, pharmaceutical active ingredients or vitamins into aqueous formulations. Pickering emulsions are also used in cosmetic products such as sun creams.

|

|

|

|

| Nanocubes act as a storage medium for hydrogen. The desire to be mobile and yet not to be without communication and entertainment had led to ever smaller and lighter electronic devices. Whether it’s laptops, cell phones or CD players, a key issue is how to power these portable devices. What batteries do today could in the future be done by mini fuel cells. Hydrogen could act as a source of energy provided that the problem of storage for its use in mobile devices can be solved. A possible storage medium for hydrogen would be nanocubes made of metal organic frameworks (MOFs), whose properties are currently being tested by BASF researchers.

|

|

|

|

| Nanotechnology makes textile fibers dirt-repellent. Nanoparticles give the surface of these textile fibers a structure with an effect similar to that of the lotus plant’s leaves. From the leaves of this plant water and dirt just roll off. This effect makes the fibers water- and dirt-repellent. Tiny particles measuring less than 100 nanometers on the textile fibers produce a similar self-cleaning effect. These surfaces are coated with billions of these nanoparticles so close together that a speck of dust wouldn't fit between them. Between a particle of dirt and the surface of the textile fibers, a layer of air is formed on which the impurities "hover" – and can simply be washed off with water. Even stubborn dirt is then easy to remove. The nanocoating has so far been applied mainly to engineering textiles, such as fabrics for tents, awnings or sunshades. But materials used for work clothing and home textiles will also be benefiting from this new technology in future.

|

|

|

|

| Securing the integrity of rock formations. These tiny particles have enormous strength since they stabilize loose rock in mining or tunnel construction, for example. The material that makes it possible is Meyco® MP 364 Flex, a resin produced from the reaction of two liquid components: modified polyisocyanate and a water glass solution. Both components are mixed on site using a static in-line mixer and pressed into the rock on the construction site. It hardens in just a few minutes, stabilizing the rock. Another advantage of the resin is that it is extremely difficult to ignite, and thus plays an important role in fire control, for example in tunnels.

|

|

|

|

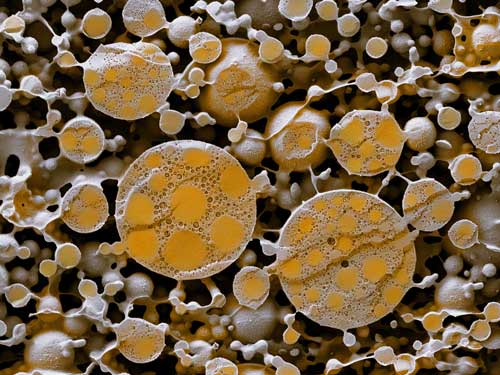

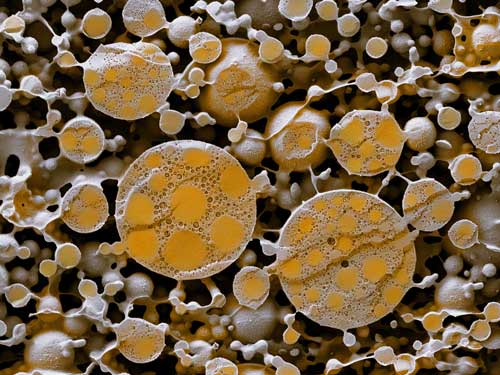

| SlurryGloss - an environmentally friendly automotive coating. The clearcoat SlurryGloss is used in automotive production line coating. Unlike other car coatings, it is environmentally friendlier because organic solvents were replaced by water.

The coating particles seen in the picture are formed during a certain production step known as dispersing of the binders in the aqueous phase. After the coating is applied, the particles melt during the baking process to produce a colorless, high-gloss clearcoat. This coat is particularly resistant to light, weatherproof and scratch-resistant and is also resistant to aggressive contaminants such as bird droppings. The network outside the coating particles consists of additives which – in combination with the adjusted particle size – are important for application of the clearcoat film and for its flow characteristics on the substrate.

|

|

|

|

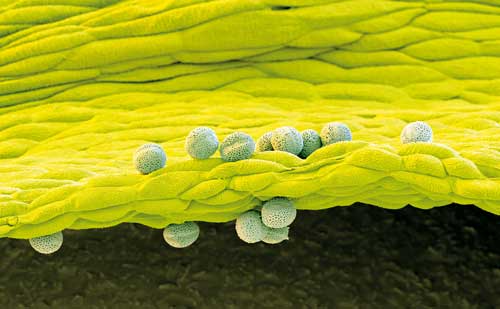

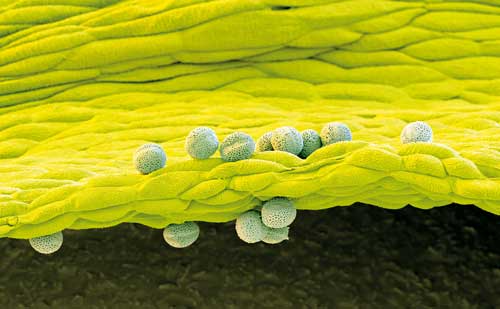

| Healthy fatty acids from plants. Researchers at BASF Plant Science have succeeded in genetically optimizing canola (oil seed rape) plants to make them capable of producing unsaturated omega-3 fatty acids. These fatty acids have a positive effect on human health because they lower the risk of stroke and cardiovascular disease. The human body is unable to produce these unsaturated fatty acids itself. This can only be done by deep-sea algae. BASF scientists have transferred the genes of the deep-sea algae responsible for the production of the fatty acids into canola plants. The oil will be added to foods such as yogurt and cheese or sold as food supplements in the form of oil capsules, for example. The electron microscopic image shows canola pollen on a petal.

|