| Posted: September 19, 2006 |

Production of high-performance thin films with laser irradiation |

|

(Nanowerk News) Researchers at the Advanced Manufacturing Research Institute of the National Institute of Advanced Industrial Science and Technology (AIST), jointly with the Department of Research and Development of the Japan Steel Works, Ltd., have established a low-cost, high-speed production technique of high-performance thin films by combining a solution process with a laser irradiation technique.

|

|

Various metallic oxide thin films have been used for devices such as solar cells, displays, sensors, capacitors, and so on. These functional thin films have been mainly produced using processes which need an expensive vacuum atmosphere. On the other hand, solution processes enable a reduction in the production costs, because the films can be produced in air. However, thin films formed using solution processes have not had sufficient performance.

|

|

In this work, by combining a production technique for oxide superconductors (YBa2Cu3O7: YBCO) using a metalorganic deposition (MOD) method, which is one of the solution processes AIST has developed, with an excimer-laser annealing technique developed by JSW, the researchers have succeeded in the improvement of their characteristics and the enhancement of production process efficiency.

|

|

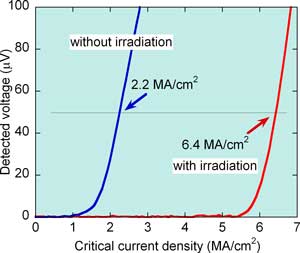

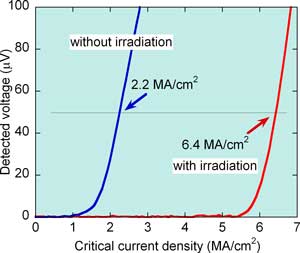

| Performance gain by laser irradiation (Source: AIST)

|

|

Using this method, they have succeeded in an enhancement of film production speed to five times that using conventional solution processes. In the production of epitaxial thin films we have achieved critical current densities, an important index of super-conduction, of six million A/cm2, a value of the world's highest class. This value is comparable to or greater than those of superconducting thin films produced by vacuum processes.

|

|

The new method enables the cost reduction and mass production of thin film devices, long tapes etc., by simultaneous patterning with masks and by continuous film formation with moving substrates. Thereby, the film production cost can be reduced to less than one tenth of those formed using vacuum processes.

|

|

These results enable not only a reduction in electric power transportation loss, which results in energy saving, the stabilization of electric power systems, which leads to safety and reassurance, and the enhancement in quality and sensitivity of mobile communications, but also the high-speed production of functional thin films.

|