| Jan 30, 2014 |

The world's first 3D printer designed to print composite materials (w/video)

|

|

(Nanowerk News) Designed to overcome the strength limitations of other 3D printed materials, the MarkForged Mark One 3D printer is the world's first 3D printer designed to print composite materials. Now you can print parts, tooling, and fixtures with a higher strength-to-weight ratio than 6061-T6 Aluminum.

|

|

Composite Filament Fabrication allows you to 3D print parts that are stronger than CNC machined aluminum by weight.

|

|

|

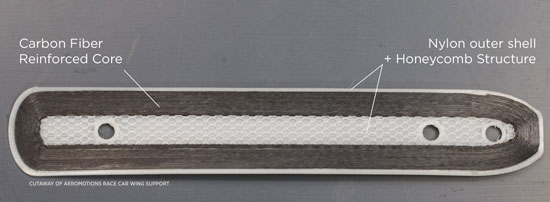

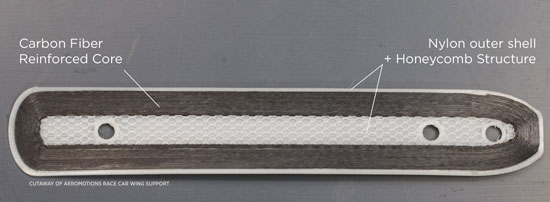

One part. Thousands of Continuous Carbon Fibers

|

|

The incredible strength of carbon fiber comes from the long, continuous strands that carry load down the entire part. This is why space shuttles, rockets, and Formula 1 cars are constructed from continuous strand carbon. And it’s how we print. Don’t settle for plastic with a dash of chopped carbon fill.

|

|

When you don’t need the world’s strongest material, the Mark One 3D prints a range of other materials to help professionals design and iterate quickly. Make super tough parts with our Nylon Filament. Or load low-cost PLA filament for those quick form and fit prints. And if you need the best cost-to-strength solution, crank out a print using their exclusive Fiberglass Filament that uses the same patented Continuous Filament Fabrication.

|

|

|