| Sep 02, 2013 |

Solar energy for sensor nodes

|

|

(Nanowerk News) Tiny solar cells applied directly to a silicon chip are a potential way of efficiently and reliably powering wireless sensor networks in the future. Above all, this would simplify large-scale applications, for instance in agriculture.

|

|

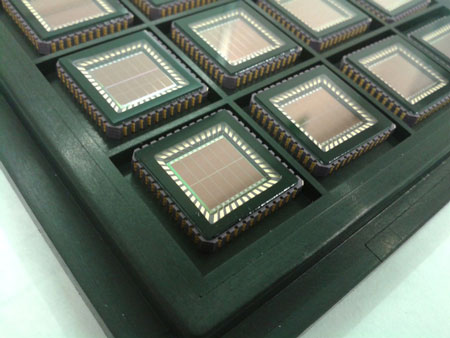

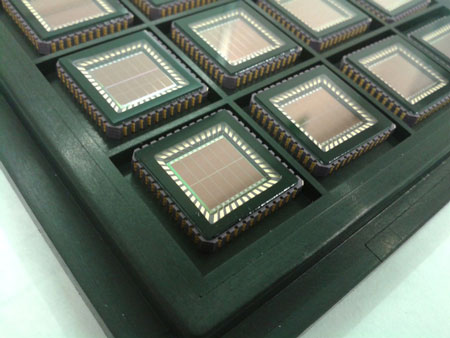

| The solar cell sits directly on the sensor module’s silicon chip. (© Fraunhofer IMS)

|

|

Almost wherever you go, the team player is more in demand than the lone wolf – after all, those who pull together get the better results. This isn’t just true of people though: sensors, too, are more powerful when part of a team. Sensor networks made up of individual sensor modules that communicate wirelessly with one another have the capacity to measure local parameters over large areas, and then to pass these data on among sensor modules to a central station. This makes sensor networks suitable for a wide range of applications, whether for fire prevention or monitoring large areas of farmland. The issue of how to power the individual sensor modules remains a sticking point in these sorts of applications. Wiring the sensors together is hardly a viable option nowadays due to the cumbersome and costly installation. What’s more, many applications require the sensor network to blend unobtrusively into the surroundings and not to have an impact on the aesthetics. An example of this would be the systems used for adjusting window positions as part of smart building management programs. Using batteries to power the sensor network does eliminate the need for inconvenient cables, but the amount of maintenance involved in replacing the batteries regularly as required should not be underestimated, particularly in large networks.

|

|

Now, researchers from the Fraunhofer Institute for Microelectronic Circuits and Systems IMS have developed an ingenious alternative based on SOLCHIP Ltd IP. The resource they have harnessed to provide power is one that is freely available in almost any location: sunlight. “We use special process steps to place a mini solar cell straight on sensor modules’ silicon chips,” explains Dr. Andreas Goehlich, who heads up the project for Fraunhofer IMS. This might sound easy at first, but it actually isn’t. For one thing, the Application Specific Integrated Circuits (ASICs) on the silicon chip cannot be disturbed in any way by later steps in the process. ASICs could be termed the brain of the sensor module, facilitating its specific functions. They are manufactured on a piece of silicon in the course of several processing steps, including ion implantation, oxidization or metal deposition.

|

|

“The structures of ASICs are extremely sensitive, which makes subsequent processing extremely tricky,” explains Goehlich. “That’s why we use a specially developed ‘soft’ processing technology that has already proved itself on a variety of different ASICs.”

|

|

Light as an energy source

|

|

In opting for mini solar cells, the researchers from Duisburg are turning to a method that is becoming more and more established in the low-power sector in particular. Energy harvesting, as it is known, is about exploiting resources in the immediate vicinity to generate small amounts of power. This means that the sensor modules are their own mini power stations, independent of external sources of electricity. Potential energy resources include harnessing vibrations or differences in temperature. Goehlich, however, believes that solar cells have a few advantages over these solutions: “Light is almost always available over long periods of time. What’s more, it is not subject to such great fluctuations in supply as other resources.” Then there is the advantage that solar energy can be converted into electricity relatively easily.

|

|

Development work is currently focusing primarily on agricultural applications. For instance, wireless, energy-autonomous sensor networks known as smartdust could be distributed over large areas of farmland. Goehlich says: “You can picture it as simply scattering the sensor nodes over the field.” These miniature smart helpers would then measure details such as the moisture in the soil or the level of sunlight and relay the data to a central interface. The farmer could then use the measurements to regulate the amount of watering or even to predict the expected crop yield. The technology is ready to be implemented and SOLCHIP Ltd. is now taking care of marketing its first product.

|