| Oct 13, 2012 |

Unique nanotechnology laboratory to build nanomedicine devices under development

|

|

(Nanowerk News) The National Science Foundation (NSF), University of Cincinnati (UC), and State of Ohio are funding the development of a “Pilot Microfactory for Nanomedicine Devices”.

|

|

An innovative research instrument will be developed to open up new avenues of research in nanotechnology and nanomedicine that will significantly benefit society. The complex research instrument will manipulate nanoscale raw materials either into intermediate materials or into miniaturized electrical/mechanical nano- architectured components which will then be used to develop prototype biomedical microdevices.

|

|

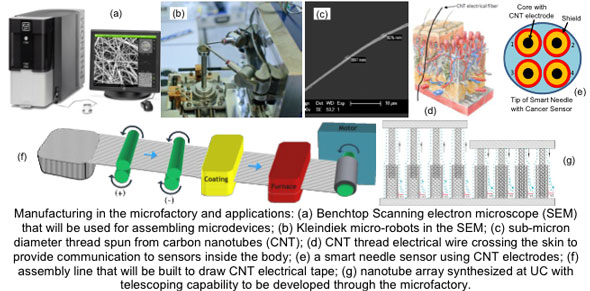

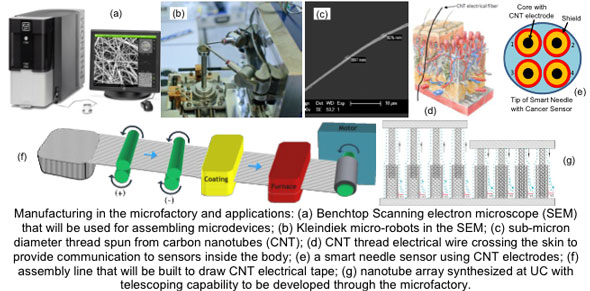

The pilot microfactory consists of four modules: Module 1-Doping, Coating, Spinning, & Magnetic Nanoparticles, see Fig. a,b,c; Module 2-Machining & Joining; Module 3- Characterization & Quality Control; Module 4-Assembly & Packaging. The modules will be combined to create a single unified assembly-line “Pilot Microfactory for Nanomedicine Devices” (“pilot” means experimental and “factory” derives from the analogy of molecular manufacturing to develop new machines). The Pilot Microfactory will exploit significant advantages that accrue when building components using nanoscale materials. For example, materials such as carbon nanotubes have high strength, high thermal and electrical conductivity, and their surface area to volume ratio is large which increases heat transfer and provides a large material surface for reacting with chemicals.

|

|

On the down side, nanoscale materials tend to aggregate or clump together in bundles which makes using them in devices difficult. When electromagnetic components have microscale dimensions, their properties also can be improved. For example, electromagnets built using nanomaterials can have extremely high magnetic flux densities and are very lightweight. This means that tiny devices and machines can have high power while their small size allows performing tasks that conventional devices are too bulky to perform. The field of medicine can particularly benefit from the use of tiny minimally invasive devices, see Fig d,e.

|

|

|

The nano-facility was designed with two important considerations in mind: 1) To be developed using available components and instrumentation which are functional and affordable, and 2) The facility should be easy to be duplicated, thus providing opportunity to share and disseminate the knowledge and experience gained through the research. The nanotechnology devices’ market (micro-wires, sensors, actuators, motors, biomedical devices) is at present nascent and the microfactory is needed to push medical device technology out of the university environment into the marketplace.

|

|

The Pilot Microfactory will be continuously improved as new materials and processing techniques become available. The goal is to produce revolutionary biomedical devices which will be put into the hands of physicians for evaluation and then transferred to industry.

|

|

The Pilot Microfactory is a long-term investment in research, technology, innovation, and education that will transition nanotechnology discoveries to applications. In developing this “microfactory” instrument, researchers will also attempt to answer several key science and engineering research questions such as: What practical capabilities in micro/nano fabrication are possible? What advances are possible in nano/micro fabrication technology using the synergistic combination of equipment? Since distances are short, will micro/nanoscale machinery enable high productivity by enabling motion cycles at ultra-high frequencies? With the microfactory, is high throughput and low cost manufacturing of high performance nano/micro scale products possible?

|

|

A new laboratory will house the microfactory and provide the facilities needed to produce advances in the science and engineering of micro-fabrication technology and the utilization of nanoscale materials to build medical micro-devices. The microfactory offers researchers a means to economically prototype next- generation devices and to incorporate nanotechnology into biology and medicine.

|

|

The first nanomaterials to be used in the facility will be CNT arrays, ribbon, yarn, and magnetic nanoparticles. CNT electrical tape will be lightweight, pliable, inert, nontoxic, and electrically and thermally conductive, Fig f. Initial devices to be fabricated will be miniature carbon electronics, electric motors, actuators, carbon wire, sensors, antennae, and actuators for use inside and outside the body. These microdevices will monitor and repair the body in ways that were not possible before. Physicians will have tools small enough to go inside the body and do what they want to do. The first devices to be developed in the facility include; (i) a smart needle sensor probe to diagnose lung tumors and prostate cancer, to be developed with Drs. Starnes, Lucas, Dong; (ii) a CNT thread nerve scaffold, developed with Dr. Pixley; (iii) a sensor to monitor the subarachnoid space, to be developed with Dr. Zuccarello; (iv) sensors for biodegradable metal implants, to be developed with Drs. Yun, Witte, Heineman; and (v) farther on down the road a sensorcyte (sensor artificial blood cell) to screen for cancer will be evaluated with Drs. Yin, Dong.

|

|

The new devices will have operational capabilities that will provide new understanding of disease, as well as new possibilities for therapies. There are also devices that have applications outside the area of medicine that may be built using the microfactory, Fig. g. The University of Cincinnati plans that US and international researchers will use this unique facility to develop devices that improve health care and create new technologies and jobs. Also, hundreds of students, parents, faculty members, colleagues, and visitors each year will see and operate the machines in the microfactory and learn about nanotechnology.

|