| Oct 24, 2012 |

Researchers develop versatile optomechanical sensors for atomic force microscopy

|

|

(Nanowerk News) Researchers from the NIST Center for Nanoscale Science and Technology have developed on-chip optomechanical sensors for atomic force microscopy (AFM) that extend the range of mechanical properties found in commercial AFM cantilevers, potentially enabling the use of this technology to study a wide variety of physical systems ("Wide cantilever stiffness range cavity optomechanical sensors for atomic force microscopy").

|

|

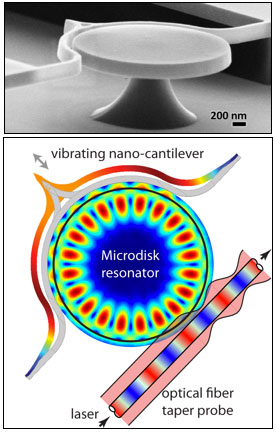

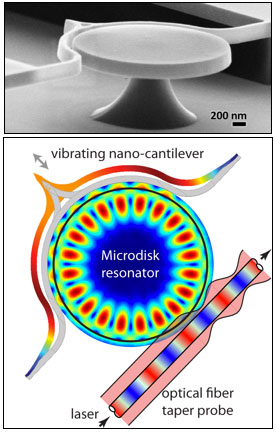

| Top: Scanning electron micrograph of the chip-based optomechanical sensor. Bottom: Schematic of the disk-cantilever sensor geometry.

|

|

AFM is an important tool for surface metrology that measures local tip-surface interactions by scanning a flexible cantilever probe over a surface, but the bulky free-space optical system commonly used to sense the motion of the probe imposes limits on the tool’s sensitivity and versatility.

|

|

Previously, the NIST team had demonstrated an alternate, chip-scale sensing platform with a more versatile readout approach in which a nanocantilever probe was integrated with interferometric motion detection provided by a low-loss optical resonator that can be coupled through fiber optics to standard optical sources and detectors.

|

|

This approach achieved remarkable displacement sensitivity. In the previous work, the cantilever spring constant, or stiffness, was fixed at a moderate value; however, in other applications, the spring constant may need to be much smaller (for studying soft materials or in weak force detection) or much larger (for high-resolution imaging). Ideally, this range of spring constants would be achieved without sacrificing displacement sensitivity or response time.

|

|

In the current work, the authors show that geometric scaling of both the cantilever and the optical resonator dimensions can enable a variation in the cantilever spring constant by over four orders of magnitude, ranging from devices that are ten times softer than the original design to ones that are one thousand times stiffer.

|

|

Importantly, these cantilevers maintain their high displacement sensitivity and achieve measurement response times that are hundreds of times faster than commercial cantilevers with similar spring constants.

|

|

Future work will focus on integrating this sensor platform into a commercial AFM system.

|