| Jan 12, 2013 |

Workshop illustrates how nanotechnology could aid sustainable design

|

|

(Nanowerk News) The Nano4Design workshop held at Central Saint Martins College of Arts and Design in London, UK, illustrated how nanotechnology could aid sustainable design. Here's a hotlist of nanomaterials and design projects currently in development.

|

|

Iceclay

|

|

An alternative nanostructured clay aerogel that is cost-effective and ultra- lightweight is being developed through an EU consortium. The ICECLAY project aims to enhance the competitiveness of SMEs by creating a new generation of low-cost and efficient insulation materials for the EU building construction industry.

|

|

Pros: The production of the material and its integrated composites will use water and eco-friendly or soluble/dispersible low-cost polymers and a cost-effective freeze-drying process. The ICECLAY material has a highly porous structure and reduced thickness.

|

|

Application: The thermal insulation material is designed for highly energy efficient buildings, retrofit and advanced HAVC systems.

|

|

Thin and flexible lightweight ICECLAY boards or films could also offer a cheaper alternative to high-performance insulation materials such as the supercritical-dried silica aerogel. The powderbased ICECLAY will be used as thermal insulation fillers for a broad range of building products, including concrete, drywalls, bricks, plaster and coatings.

|

|

The project will be completed in 2014. If you are interested in taking part in the ongoing group, visit the ICECLAY project website.

|

|

Solaveil

|

|

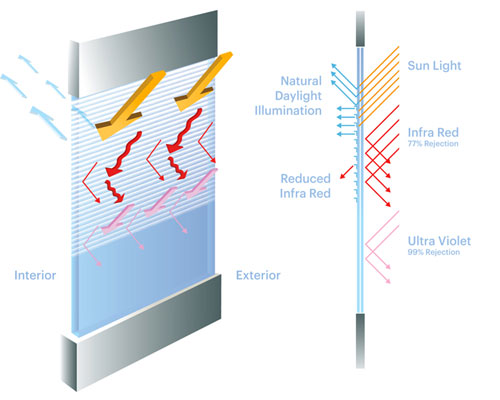

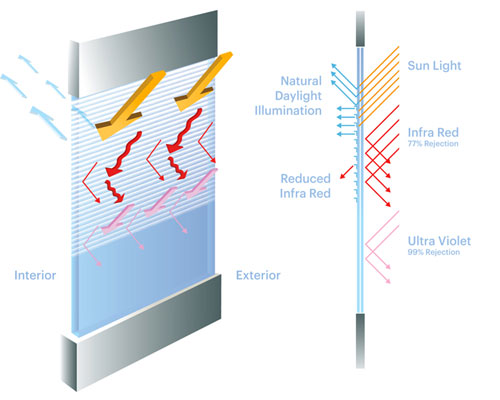

This simple technology is formed from a thinly layered material that is made by adding controlled amounts of carbon nanotubes to thermoplastic fibres. The material is printed using 3D surface treatment. The print is then applied to the glazing of a window to control solar radiation and glare, and offset artificial lighting. The patterns on the material can be scattered, optimised and configured to each building’s requirements.

|

|

At present, there are three main variations of Solaveil technology. The first is an antimicrobial version that protects against Staphylococcus aureus and E. coli and can be used in hospitals or care homes instead of blinds. The second is a UV-blocking surface that harvests natural light and reduces overall temperature by 9°C. It is designed to improve concentration in office and school environments that would otherwise use fluorescent lighting.

|

|

|

The latest variation of the technology is a security and blast performance veil, designed to prevent glass shattering on impact. It provides protection against explosions, storm damage and theft.

|

|

Pros: According to product designer and founder of the company, Brian Hughes, the Solaveil material has a peel strength of 985g/cm, a tensile strength of 2,110kg/cm and a break strength of 43kg/cm. He also claims that the material offers a 25% building energy saving.

|

|

Nanocellulose hemp fibres

|

|

The Forest Products Laboratory branch of the US Forest Service has given a grant of US$1.7m to a pilot plant that will work on the production of cellulose nanocrystals. It is estimated that the plant will contribute US$600bln to the US economy by 2020.

|

|

Pros: This material out-toughs both carbon fibre and Kevlar while still being lightweight and is renewable and cheap to produce. Applications are far-reaching due to its optical, thermal and electronic properties, and can range from strengthening agents in paper manufacture to coating additives and barrier materials for packaging. While not a new material, investigations into wider applications are underway, such as in boards, walls, floors, coatings and retrofitting or building panels.

|

|

Professor Mizi Fan, who leads a nanocellulose research group at Brunel University, comments, ‘Its strength is comparable to aluminium and it has a strong surface area and high aspect ratio, so it can be easily combined with materials such as clay. Another benefit is that 25% of its mass is already nanostructured.’

|

|

Challenges: Moisture. The next step is to improve the material’s hydrophobic properties through surface engineering.

|

|

Polluted patterns

|

|

Textile and surface design graduate at Central Saint Martins, Alessia Giardino, has created an environmentally adaptive architectural solution that replicates nature by using living organisms to create surfaces that are 'responsive, informative and decorative'.

|

|

Concrete Lace (pictured below) is a combination of concrete, organic materials, nanotechnology and textile techniques that can be used to regenerate urban and domestic environments. The base material is a concrete tile processed through photocatalytic cement, an innovative, sustainable technology containing TiO2.

|

|

'The TiO2 reacts with light and so is able to break down pollution in the air, while purifying it,’ says Giardino. The TiO2 is applied using serigraphy printing, traditionally used in graphics and textiles. The parts that are protected by the TiO2 maintain a clean surface and prevent ageing and yellowing, while the uncovered surface turns into a catalyst for polluting substances and forms a pattern, making these surfaces look more appealing.’ Giardino is now seeking research and commercial partners to take the technology to market and test the technology on other substrates.

|

|

New advanced insulation phase change materials (NanoPCM)

|

|

This low-cost stable thermal storage component is based on the anchorage at nanoscale of organic PCMs between the polymeric chains of selected polymers. The PCMs will be based on byproducts of different industries.

|

|

A NanoPCM group has been formed of EU companies, universities and housing development agencies. The project, which will be completed in May 2013, will develop a number of low-cost and improved PCM for high performance insulation components in existing buildings. The material can be used in passive cooling and heat applications.

|

|

The project will also aim to develop a thermal insulation inorganic nanofoam with thermal storage capacity. The next phase will improve the thermal behaviour of the materials developed with the introduction of high thermal conductive nanomaterials, CNT or CNF inside their structures. In addition, the group will look to enhance organic phase change microcapsules with the incorporation of high thermal conductive nanomaterials in the shell, which will provide better thermal transfer to the organic paraffin inside. For further information, visit www.nanopcm.eu

|