| Mar 13, 2013 |

Optical sensing device may lead to quicker, more efficient diagnostics

|

|

(Nanowerk News) A twist on thin-film technology may provide a way to optically detect and analyze multiple substances simultaneously, leading to quicker diagnostics in such industries as health care and homeland security, according to Penn State researchers.

|

|

One current optical-sensing technology can launch and guide a single light wave, called a surface-plasmon-polariton wave -- SPP wave -- that travels along the flat interface of the sample to be analyzed and a metal film. The SPP wave is launched by sending a light beam through a prism to the other face of the metal film. A photon detector eventually collects the beam that was reflected back into the prism. Any change in the optical properties of the sample critically alters the reflected beam.

|

|

The detector records this alteration, which analysts can then use as an optical fingerprint to help them identify the changes in the chemical composition of the sample, according to Akhlesh Lakhtakia, Charles Godfrey Binder Professor of Engineering Science and Mechanics.

|

|

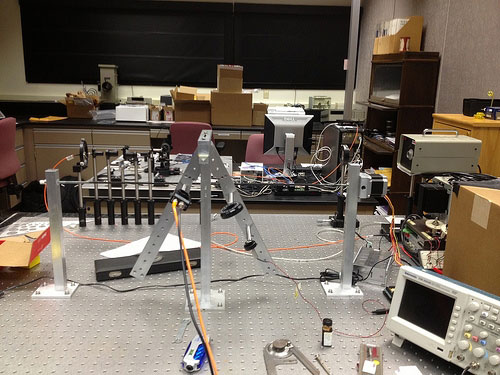

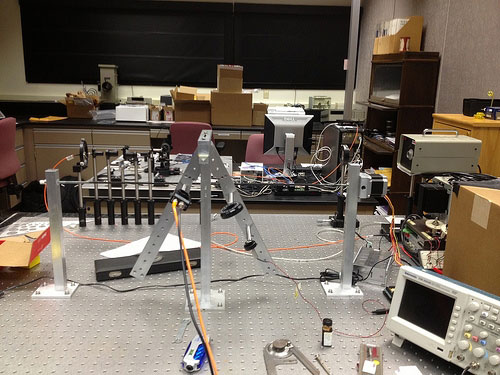

| The right leg of this optical-sensing device contains a light source that shines a beam up into a prism. The sample rests on the top of the prism. Eventually, the beam is sent down the other leg of the device into a photon detector, which helps analyze the sample.

|

|

However, because the technology allows for only one SPP wave of a certain frequency to be guided through the device, the properties of only one substance can be analyzed for each sensor, said Lakhtakia, who worked with Stephen Swiontek and Drew Pulsifer, both doctoral students in engineering science and mechanics.

|

|

"This is a very effective technology and it's being used in many industries, such as pharmaceuticals, agriculture and forensics, for example," said Lakhtakia. "But allowing only one SPP wave per sensor is a disadvantage."

|

|

The researchers designed a thin film that can create additional channels for the SPP waves. This thin film, which is attached to the metal surface, is porous and can be infiltrated by fluids that can later be analyzed.

|

|

Conventional thin films are made by layering clumps of atoms in rows on a surface, or substrate. To make more channels for the SPP waves, Pulsifer and Swiontek slowly rotated the substrate during the fabrication of the thin film, sculpturing it to create nanoscale springs, so that the regions between the springs can be infiltrated. Lakhtakia and his students had showed earlier that the interface of this type of thin film and a metal film can guide many SPP waves at a fixed frequency.

|

|

To test the new optical sensing technique, the researchers built a prototype of an optical-sensing device that has two legs. On one leg, a laser focuses a beam of light toward a prism that rests at the apex of the device. The peak of the prism points down, so that the researchers can add the metal film and sculptured thin film to the flat surface on the prism's hypotenuse.

|

|

The light beam is then refracted toward a photon detector on the opposite leg of the device.

|

|

The researchers, who report their findings in Scientific Reports ("Optical sensing of analytes in aqueous solutions with a multiple surface-plasmon-polariton-wave platform"), recorded multiple SPP waves through a sample containing water, one containing water and sucrose and a control sample.

|

|

Lakhtakia said the team performed a series of sensitivity tests on the system and found that the method was nearly as reliable and as accurate as state-of-the-art technology in detecting and analyzing substances.

|

|

"It gives us hope that we will have a nice system to work with and that we can even increase reliability and accuracy," said Lakhtakia.

|

|

The system could be optimized by experimenting with different substrate materials and by adding extra photon detectors and optical filters, according to the researchers.

|

|

"This is a billion-dollar industry," said Swiontek."If we can detect more than one analyte reliably and we can optimize the process, I think there's a possibility that it can replace the traditional method."

|

|

According to Swiontek, if the technology is even further refined and optimized, it may lead to significantly smaller diagnostic equipment.

|

|

Lakhtakia initially saw uses for the technology in homeland security and defense industries. For instance, soldiers may need to rapidly assess if water sources in occupied territories are safe. It could also be used in places closer to home.

|

|

"For instance, it could be used to test water if agents infiltrated the United States and put poisons in our water bodies, not just lakes and streams, but reservoirs that supply urban areas," said Lakhtakia.

|