| Jul 12, 2013 |

Lab-on-a-chip technology gets a flexible upgrade

|

|

(Nanowerk News) Microfluidic devices move liquids through tiny, hair-sized pathways carved into glass slides and have distinct advantages over traditional laboratories when it comes to medical diagnostics. At these reduced scales, fluid transport is enhanced by factors such as diffusion and high surface-to-volume ratios, making testing procedures much faster. By constructing parallel arrays of microfluidic pathways, researchers are working to produce ‘lab-on-a-chip’ technologies that allow multiple biological tests to be performed using just a drop of blood or urine. In a development that promises to make lab-on-a-chip devices more portable and economic to construct, Yo Tanaka from the RIKEN Quantitative Biology Center and colleagues have now produced a new type of microfluidic control valve that takes up significantly less space on a microchip than existing approaches ("An active valve incorporated into a microchip using a high strain electroactive polymer").

|

|

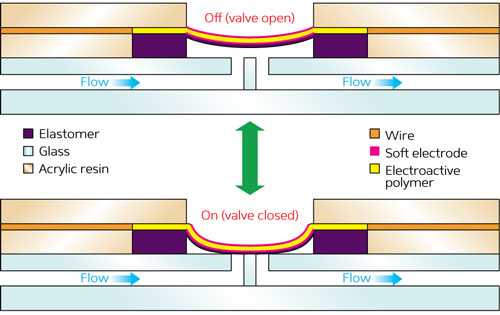

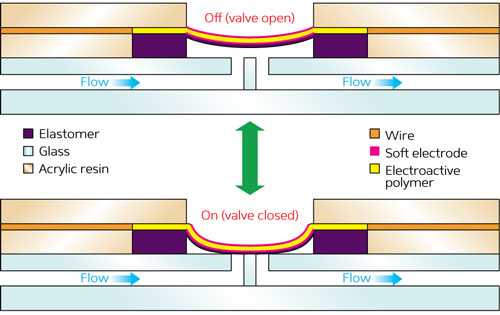

| A novel electroactive polymer stop valve for lab-on-a–chip technology.

|

|

In the majority of today’s microfluidic devices, silicone pneumatic valves are used to manipulate liquid samples. Pneumatic valves, however, require noisy compressors and complicated air channel systems, which are often too bulky for practical lab-on-a-chip applications. Piezoelectric actuators—inorganic crystals that change shape when electrically stimulated—are feasible alternatives, but while piezoelectric materials are less obtrusive than pressurized air technology, they are excessively large when compared to the size of the microchip itself.

|

|

Tanaka and his colleagues instead investigated the remarkable properties of electroactive polymers. These materials are rubber-like organic compounds that expand and contract when exposed to an electric current. As electroactive polymers can exhibit large mechanical strain force at small scales, the team deduced that creating membranes incorporating these materials could be a promising way to miniaturize microfluidic control valves.

|

|

After experimenting with many valve shapes, the researchers settled on a micrometer-sized, dome-shaped polymer diaphragm sandwiched between soft electrode sheets (Fig.). They tested its ability to stop flow by fabricating it on top of a small hole drilled into a microfluidic channel. By monitoring fluorescent polystyrene tracking beads using high-speed video cameras, the team saw that stimulating the electroactive polymer caused the diaphragm to expand and close off the microchannel at sub-second speeds, nearly identical to the response time of piezoelectric actuators but with an order-of-magnitude smaller form factor. Furthermore, the polymer structure strongly resisted leaks because of its resilient structure.

|

|

The researchers note that the improved size-scaling of their valve system should prove more efficient for the sorting of biological cells than current fluorescent technology. Other—more mobile—applications also may be on the horizon. “Many portable devices for personal diagnosis, environmental analysis, or fuel cells could benefit from these miniaturized valves,” says Tanaka.

|