| Jul 31, 2013 |

Supergluing liquid marbles produces stable liquid capsules

|

|

(Nanowerk News) ‘Liquid marbles’ are a peculiar new substance made by rolling water droplets into powders incapable of dissolving in water. The resulting micro- and nanoscale-particles act like soft solids, and can speed along surfaces without leaving water marks. Such non-stick, hydrophobic behavior has potential application in drug-delivery and microfluidic technology. However, liquid marbles suffer from erratic structures prone to collapse. Jia Min Chin, Jianwei Xu and co-workers from A*STAR’s Institute of Materials Research and Engineering, and Institute of Bioengineering and Nanotechnology, have now developed a scheme to stabilize liquid marbles quickly and safely using vapors from ordinary superglue ("Supergluing MOF liquid marbles").

|

|

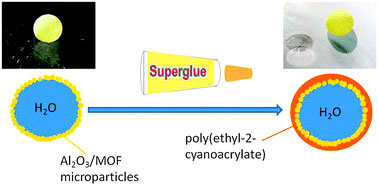

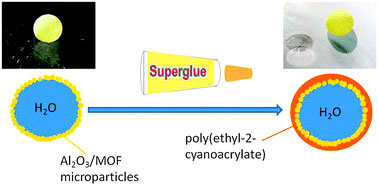

| Growth of NH2-MIL-53(Al) on alumina microparticles followed by post-synthetic modification with perfluorooctyl or caproic groups produces highly hydrophobic microparticles which are utilized for the formation of liquid marbles. Interfacial polymerization of ethyl-2-cyanoacrylate on the surface of the liquid marbles produces stable liquid capsules. (© RSC Publishing)

|

|

Many powders used to make liquid marbles are based on metal–organic frameworks (MOFs), a type of crystal in which metal ions are interspersed with rigid organic molecules. Chin, Xu and co-workers investigated whether MOFs known as NH2-MIL-53(Al), a combination of aluminum atoms and amino-phenyl compounds, could grow directly on the surfaces of alumina microparticles. This approach, the team theorized, might provide extra structural control over liquid marble stability. After confirming MOF growth with x-ray measurements, the team modified the microparticles with either hydrocarbon or fluorocarbon chains, converting them into ‘superhydrophobic’ powders. Then, they produced alumina-supported liquid marbles by adding micro-sized water droplets.

|

|

The researchers found that their new liquid marbles had greater stability than usual, thanks to its reactive amino groups and high surface roughness. Yet, they sought to further boost its resilience. When they spotted small gaps between the MOF–alumina microparticles with scanning electron microscopy, they inferred that certain gas molecules might enter these pores and create a cross-linked network through a process called air–liquid interfacial polymerization.

|

|

Forensic scientists often use superglue vapors to uncover fingerprints at crime scenes; the trace water in finger smudges reacts rapidly with adhesive fumes and generates visible polymer structures. Taking a cue from this method, the team exposed their MOF–alumina liquid marble to superglue vapors in a Petri dish and saw a rigid polymer casing form within a few minutes. Chin notes that this procedure requires no heat, UV radiation, or chemical initiators — an unprecedented finding for liquid marble encapsulation. “Furthermore, the only solvent required was water, qualifying this as a ‘green’ reaction,” she adds.

|

|

The liquid marble retained its unique non-wetting behavior on surfaces, even with the protective polymer coating. These stabilizing attributes promise big dividends in areas such as gas purification and personal care products: two patents have already been filed this year in efforts to commercialize this technology.

|