| Oct 04, 2013 |

Super-thin conducting power

|

|

(Nanowerk News) Magnets made from coils of superconducting wire can maintain current flows for years without losing energy. Such superconducting magnet systems provide significant advantages for technologies such as medical scanners, spectrometers, particle accelerators and high-speed trains. However, most superconducting materials only achieve their ideal conducting properties at temperatures far below zero.

|

|

A research team led by Hideaki Maeda from the RIKEN Center for Life Science Technologies has now developed an ultrathin insulation layer that enhances the efficiency of magnetic coils based on the promising high-temperature superconducting compound REBCO ("An ultra-thin polyimide insulation coating on REBCO conductors by electrodeposition produces a maximum overall current density for REBCO coils").

|

|

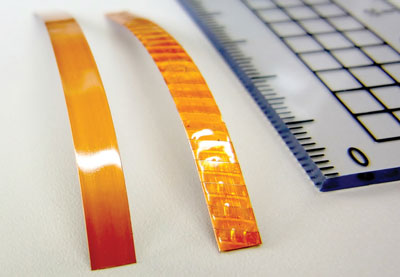

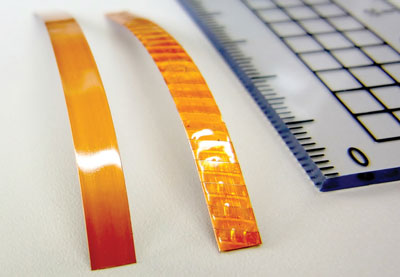

| Figure 1: REBCO wires with an ultrathin insulation layer (left) provide double the current density of conventionally insulated REBCO wires (center). (©2013 Hideaki Maeda, RIKEN Center for Life Science Technologies)

|

|

Wire coils made out of REBCO, a rare-earth barium copper oxide, are capable of withstanding the intense stresses that occur when the magnet charges, allowing them to produce stronger magnetic fields than traditional superconducting wires. However, REBCO does not yet perform efficiently because it requires a thick electrical insulation layer, which lowers the maximum current density of the conducting coil that can be produced.

|

|

“The REBCO wires themselves are very thin—between 100 and 150 micrometers—but conventional layers of electrical insulation are about the same thickness. This reduces the effective amount of superconducting wire in every coil,” explains Maeda. “To achieve a higher current density in smaller coils, the insulation layer needs to be much thinner.”

|

|

Maeda and his team used a technique called electrodeposition to coat the REBCO wires with a uniformly thin layer of polyimide insulation. The process involves immersing wire in a bath of polyimide colloidal solution and establishing an electric field between the wire and an electrode in the bath. The electric field causes the polyimide particles to migrate to the wire and coat the superconductor’s surface.

|

|

Baking the wire in a furnace for a few minutes to harden the polyimide coating produced a conductor that was coated uniformly with an ultrathin layer of insulation ten times thinner than any previous insulation layer (Fig. 1).

|

|

“With this new REBCO superconducting wire, we can achieve a current density that is double that of a conventionally insulated REBCO coil. We can also make the coils five times smaller than before,” explains Maeda. “As a result, the conductor can generate higher magnetic fields with smaller devices, opening up new potential applications.”

|

|

The researchers believe that their new REBCO coils could make it possible to produce a nuclear magnetic resonance spectrometer capable of generating magnetic fields stronger than 23.5 tesla—the magnetic field limit for conventional superconducting wires.

|