| Oct 22, 2013 |

A simple method to fabricate self-cleaning, antireflection coatings

|

|

(Nanowerk News) Low-cost antireflection coatings (ARCs) on large optical surfaces are an ingredient-technology for high-performance solar cells. While nanoporous thin films that meet the zero-reflectance conditions on transparent substrates can be cheaply manufactured, their suitability for outdoor applications is limited by the lack of robustness and cleanability.

|

|

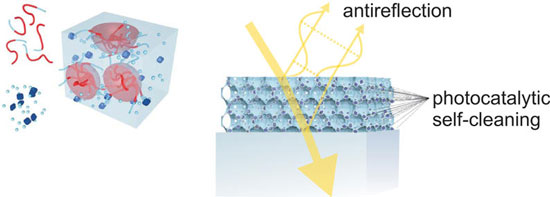

In a new paper in Nano Letters ("Self-Cleaning Antireflective Optical Coatings"), an international research team now reports the manufacture of a highly porous ARC with high TiO2-nanoparticle loading that combines excellent optical antireflectivity with efficient photocatalytic activity.

|

|

| The fabrication strategy relies on the self-assembly of a blockcopolymer in combination with silica-based sol-gel chemistry and preformed TiO2 nanocrystals. The spontaneous dense packing of copolymer micelles followed by a condensation reaction results in an inverse opal-type silica morphology that is loaded with TiO2 photocatalytic hot-spots.

|

|

The team's fabrication strategy relies on the assembly of high molecular weight blockcopolymer micelles that assemble into a sacrificial opal-type structure. After solidification by a sol-gel condensation reaction, this gives rise to a silica network with porosities of up to 73%. This enabled the addition of high weight fractions of TiO2 nanocrystals without compromising the refractive index required for high performance ARCs.

|

|

The combined antireflective and photocatalytic properties should substantially improve the long-term optical properties of porous ARCs, or even remove applied contaminants such a fingerprints.

|

|

The low-temperature ARC processing enables the coating of flexible plastic substrates, paving the way for low-cost large area ARC manufacture.

|