| Oct 25, 2013 |

Scientists develop easy way to print graphene electronics

|

|

(Nanowerk News) Scientists at University of Perugia (Italy) in collaboration with Grafen Co. (Turkey) have discovered practical and cheap method to fabricate graphene based printed electronics.

|

|

Dr. Luca Valentini, assistant professor of the Materials Science and Technology Chair at the University of Perugia, together with his colleagues used only ordinary cellulose paper and pen to design a transfer process of graphene patterns. Writing in the December 15, 2013 issue of Materials Letters ("Transfer writing of foldable graphene nanoplatelet patterns on paper substrates"), the scientists say their approach could find application in flexible biodegradable electronics being cellulose substrate easily recyclable or biodegradable at a low cost and attractive for the realization of a sustainable flexible technology.

|

|

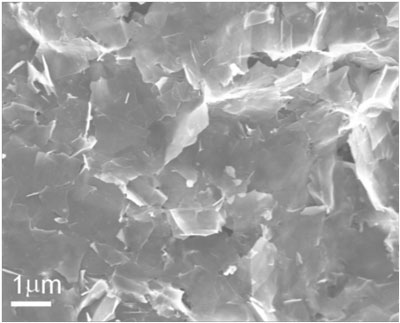

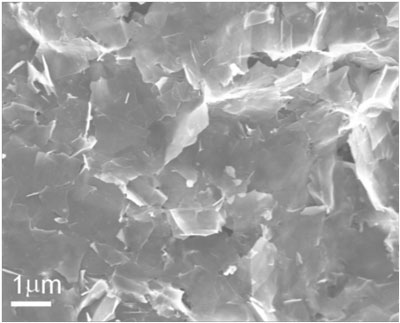

| Graphene nanoplatelets drop cast onto glossy photopaper.

|

|

Printed electronics is an emerging area that can revolutionize low cost electronics industry by bringing customary fabrication techniques such as screen printing, gravure or even inkjet printing to the field. By this technology, roll-to-roll, high speed, continuous and greener production of simple electronic circuits is possible in a durable and flexible structure.

|

|

Printed electronics has particularly strong potential in the manufacturing of inexpensive, disposable or extremely bulk consumed electronic components like intelligent packaging, anti-counterfeit, e-textiles and large-area electronics like active posters. Printed electronics is not only for those, but also some advanced applications, from biocompatible devices to flexible displays, are expected.

|

|

The most important issue in this field is the design of suitable “inks” containing a conductive ingredient that can form films when dried. Graphene nanomaterials naturally are among the most promising conductive ingredients by their extreme conductivity and mechanical and chemical resistance.

|

|

In their study, the research team first prepared liquid dispersions of Grafen®-GNP from Grafen Co. which is one of the most pristine graphene forms in the commercial market. Then they drop casted that dispersion onto ordinary glossy photopaper as a transfer substrate. The idea, here it comes now, the researchers sandwiched the coated glossy paper with a rough paper and then used a simple ballpoint pen to draw patterns onto backside of the graphene coated glossy paper. In this way, graphene patterns are transferred onto the rough paper as line patterns that can mimic an electronic circuit. |

|

Electrical conductivity of graphene line patterns fabricated by the technology above is excellent and survived after 500 cycles of folding. Manipulating these line patterns is extremely easy, for example you can remove it wherever you want just by using an eraser.

|

|

“Dr. Valentini and his team have provided a proof of concept for practical printed electronics technologies employing graphene” said Ibrahim Mutlay, Chief Science Officer of Grafen Co. “their paper will serve as a background for future research ideas in this field”.

|