| Posted: Sep 04, 2009 | |

Turning plastic waste into a feedstock for making nanomaterials |

|

| (Nanowerk Spotlight) There is no denying the fact that plastic wastes have caused serious environmental problems – and continue to do so. Everyday plastic products, for instance water bottles or plastic bags from supermarkets, are so durable that they will either not rot at all or have long biodegradation periods of 50 years and more ("Biodegradability of degradable plastic waste"). | |

| Although so-called 'biodegradable' plastic products typically contain chemicals that help them fragment, the additives do not render the plastic biodegradable (see: "Degradable plastics: A critical review"). While it is important to develop various techniques for the elimination of plastic wastes – landfills, incineration etc. – these solutions typically present several disadvantages such as re-entering the environment and cause 're-pollution', loss of natural resources, or depletion of landfill space. | |

| Researchers in China have now developed a technique that uses waste plastics as carbon source for synthesizing silicon carbide (SiC) nanomaterials. This may actually provide an effective method to help solve the environmental pollution of waste plastics. | |

| By the way, in a previous Nanowerk Spotlight we have reported about another "plastic waste to nanomaterial" approach, also by a Chinese research group, that developed a nanocomposite material that not only has superabsorbent capabilities but also utilizes waste polystyrene foam – better known under its trade name styrofoam ("Novel nanocomposite material to combat white pollution"). | |

| "We synthesized 3C-SiC nanomaterials by polyolefin and silicon powder via the sulfur-assisted approach at a relatively low temperature of 350–500°C in a stainless steel autoclave" Yitai Qian, a professor at the Key Laboratory of Colloid and Interface Chemistry, School of Chemistry and Chemical Engineering, at Shandong University tells Nanowerk. "The as-obtained 3C-SiC contains a small amount of amorphous graphite and silicon, which can be removed by a refluxing process." | |

| This route, presented in the August 12, 2009 online issue of Nanotechnology ("The synthesis of nanostructured SiC from waste plastics and silicon powder") may provide an effective method to solve the environmental pollution of waste plastics. | |

| SiC is a useful functional ceramic material with excellent mechanical properties, high physical and chemical stability, and high thermal conductivity. Generally, it is used in abrasives and the metallurgical and refractory industries. Utilizing the plastic wastes as carbon source for preparing SiC is beneficial to energy saving, emission reduction and environment protection. | |

| "We have used three typical kinds of plastic wastes have been used as carbon source," explains Dr. Zhicheng Ju, first author of the paper: "waste detergent bottles or beverage bottles (main components: high density polyethylene – HDPE); various waste plastic bags (main components: low density polyethylene – LDPE); beverage, food and other liquid containers (main components: polyethylene terephthalate – PET), although other types of waste plastics may be also used as carbon source to prepare SiC or other carbides nanomaterials." | |

| Ju continues to explain that the team produced the SiC nanomaterials by using these plastic wastes together with silicon powder, sodium, magnesium and sulfur powder as reactants in an autoclave at a 350-500°C where the reaction pressure is usually not more than 10 MPa (theoretical calculated value). We cleaned and treated the products of the preceding step by a refluxing process with aqueous HClO4 and a mixture of HF and HNO3 respectively to obtained the pure SiC powder." | |

|

|

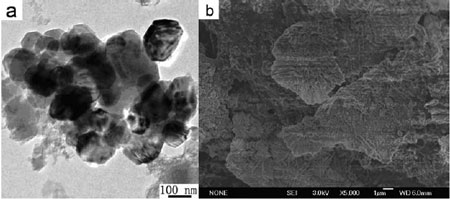

| TEM and SEM images of the sample from PET. (a) irregular platelet-like crystals (about 20% based on TEM). (b) two-dimensional lamella resembling crepe (about 60% based on SEM). (Image: Zhicheng Ju and Yitai Qian, Shadong University) | |

| The X-ray powder diffraction showed the researchers that the samples from HDPE and LDPE are all highly crystalline 3C-SiC while the sample from PET was 3C-SiC with a small content of 2H-SiC. The average yield of silicon carbide is about 39% based on the amount of Si powder. | |

| While initially the crude silicon carbide products contained a small amount of amorphous graphite and some crystalline silicon, the team found that by optimizing the experimental parameters they can get their samples almost pure. Even if the sample contains carbon and silicon, most of them can be removed by repetition of the high-speed centrifugation process employing a mixture of bromoform and acetone. | |

| Observing the structure and morphology of their SiC material by TEM, SAED and HRTEM, the researchers found hexagonal platelet-like crystals (about 40% based on TEM) and irregular nanoparticles in the sample from HDPE. The length of the fixed edges of these SiC hexagonal platelet-like crystals was 300-500 nm, and the thickness was about 50 nm. The nanowires (about 35% based on TEM) and irregular nanoparticles were also observed in the sample from LDPE. The average diameter of the nanowires is about 50 nm and the length is up to tens of micrometers. A lot of two-dimensional lamella resembling crepe with the thickness of about 100 nm and about 20% irregular platelet-like crystals were observed in the sample from PET (see figure above). | |

| "At present, sulfur powder is necessary in the reaction route to fabricate SiC" says Qian. "Whether or not the introduction of sulfur powder effects the properties of the silicon carbide material needs further investigation. Also, how to improve the yield and lower the formation temperature are priority issues for us. Finally, we are planning further experiments on how to prepare these SiC nanomaterials from plastic wastes on a large scale that would be suitable for industrial use." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|