| Posted: Jan 27, 2010 | |

Nanotechnology drives electronic paper displays |

|

| (Nanowerk Spotlight) With all the buzz that is being created by portable e-book readers like Amazon's Kindle or the red-hot rumor mill about Apple's upcoming introduction of a tablet computer (the iPad, iSlate, iTablet, Magic Slate, or whatever it will be called), it's worth taking a look at one of the advanced display technologies – also often referred to as electronic paper – that make these devices happen. | |

| Unlike a conventional flat panel display, which uses a power-consuming backlight to illuminate its pixels, electronic paper reflects light like ordinary paper and is capable of holding text and images indefinitely without drawing electricity, while allowing the image to be changed later. Because they can be produced on thin, flexible substrates an due to their paper-like appearance, electrophoretic displays are considered prime examples of the electronic paper category. | |

| Electrophoretic displays already are in commercial use, for instance in the Kindle or in the Sony Reader, but so far the displays are mostly black and white. There are still cost and quality issues with color displays. New work by nanotechnology researchers in South Korea shows that organic ink nanoparticles could provide an improved electronic ink fabrication technology resulting in e-paper with high brightness, good contrast ratio, and lower manufacturing cost. | |

|

|

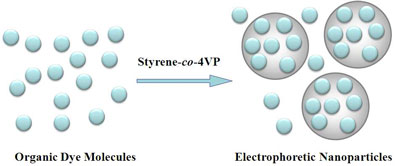

| Schematic presentation of the formation of dye molecule encapsulated electrophoretic particles. (Reprinted with permission from Wiley-VCH Verlag) | |

| "Our work is the first report on a mixed coloring electrophoretic image display technology with all-organic charged colored ink nanoparticles" Young Soo Kang tells Nanowerk. "We have successfully prepared electrophoretic ink nanoparticles with a dispersion polymerization method, encapsulating organic dyes such as red, blue and yellow molecules. Positive or negative surface charge of the ink particles could be induced using CTAB or SDS surfactant during synthesis." | |

| With their new technique, Kang, a professor in the Department of Chemistry and head of the Nanostructured Material Lab at Sogang University, and his team can control both the size and the surface charge density of the ink particles by varying the concentration of the surfactants. | |

| The chargeability of the ink particles is a key factor in determining the speed or efficiency of the electrophoretic image displays. | |

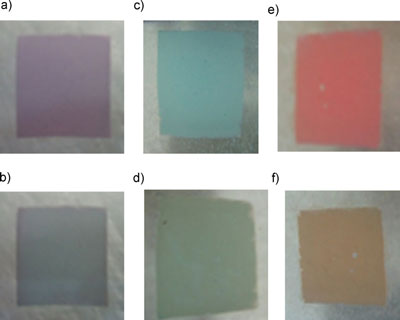

| "The mobility of the ink particles in our technique is derived from the charge of the embedded ionic surfactant" explains Kang. "Each of the particles can have a positive or a negative surface charge. They can be moved by the electrostatic force when an electric field is applied. Electrophoretic cells prepared with the charged colored ink particles can display different colors on application and change of the bias voltage. We expect these monodisperse ink particles prepared with organic dye molecules to be very useful in e-paper displays in a cost-effective way." | |

|

|

| Electrophoretic colored ink display cells: a) blue and red ink mixed electronic ink slurry without bias, and b) after application of bias voltage; c) yellow and blue ink mixed electronic ink slurry without bias, and d) after application of bias voltage; e) yellow and red ink mixed electronic ink slurry without bias, and f) after application of bias voltage. (Reprinted with permission from Wiley-VCH Verlag) | |

| The team has published their findings in a recent issue of Advanced Materials ("Encapsulated-Dye All-Organic Charged Colored Ink Nanoparticles for Electrophoretic Image Display"). | |

| Kang notes that there are still limitations to this approach with regard to obtaining a full color display using all-organic charged color electronic ink. | |

| "To develop full color display devices, we have to get the ink particles to have different surface charges," he explains. "But currently we only have positive and negative charges. So we are planning to have two kinds of surface forces – one to be electrophoretic and the other one to be magnetic by coating magnetic nanoparticles on the surface of the dye molecules. Electrophoretic mobility and by magnetic force should give us the required mobility to achieve full color electrophoretic displays." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|