| Posted: Sep 02, 2010 | |||

Polymer carpets - a new class of nanomaterials for NEMS and MEMS |

|||

| (Nanowerk Spotlight) Unlike most biological membranes, polymeric, nanometer-thin membranes are very stable and can withstand considerable pressure. This is an essential requirements for separation processes such as in water purification and desalination. Because their mechanical stability can be combined with flexibility and chemical functionality, polymer nanomembranes are also intensely researchers as materials for actuators and microsensors. They have also entered the biomedical field as artificial nacre and as a novel material used in surgery. | |||

| Among the techniques developed for fabricating defect-free and mechanically robust nanomembranes are layer-by-layer (LbL) assembly of polyelectrolyte multilayers; crosslinking of Langmuir–Blodgett; and self-assembled monolayers (SAMs). A more recent approach for the preparation of mechanically stable nanomembranes is the 'high-density crosslinking' of a spin-coated precursor solution. Due to their extraordinary sensitivity and dynamic range, highly crosslinked nanomembranes are regarded for next-generation pressure, thermal, tactile, and acoustic sensors. | |||

| However, the high crosslinking reduces the interactions between the polymer chains and the environment and thus impairs the sensitivity and flexibility of the films – a significant disadvantage for the fabrication of chemical- or bioresponsive polymer-based nanomembranes. For that reason, soft and stimuli-responsive polymer brushes have been the system of choice for the development of adaptive layers as actuators and sensors. These brushes react more quickly and has a higher sensitivity towards external stimuli. | |||

Researchers in Germany have now developed the first freestanding polymer brush, grafted from a crosslinked monolayer (nanosheet) that provides mechanical stability and structural integrity. Because of the morphological similarity, they refer to this structure as a polymer carpet.

"Polymer carpets exhibit remarkable and unprecedented properties combining extreme thinness, mechanical and chemical stability, robustness, flexibility, and (chemical) sensitivity" writes the team. "Moreover, it was found that the morphology of polymer carpets quickly and reversibly responds to solvent quality and pH by buckling and significant change of their physical properties (i.e., optical characteristics and wetting)." According to the researchers, this cooperative change of the entire layer morphology may be applied for the development of integrated nano-/micromechanical systems, such as actuators or sensors. They also point out that, because of the high aspect ratio spanning several dimensions (nanometer thickness and micro-to-centimeter sheets), devices that couple minute changes to macroscopic effects are possible. |

|||

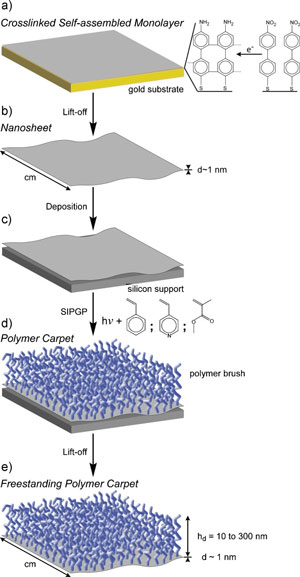

| To fabricate the polymer carpets, the team prepared a 1-nm thin nanosheet by electron-beam-induced crosslinking of a biphenyl SAM. After detachment of the crosslinked monolayer from the substrate and deposition onto a solid silicon support, the nanosheet was used as a two-dimensional template to grow a polymer brush by surface initiated polymerization, forming the polymer carpet. | |||

| Like a real carpet, a polymer carpet thus consists of a soft and flexible brush that is (covalently) attached to a thin and rigid 2D framework. | |||

| As an additional benefit, the simple two-step procedure – electron-induced SAM crosslinking followed by self-initiated surface photo polymerization and photografting (SIPGP) – for the preparation of polymer carpets allows the introduction of multiple chemical functionalities within the layer by varying the monomer and/or by polymer analogue reactions. | |||

| Gölzhäuser and Jordan say that the thickness as well as its mechanical properties of their polymer carpet can be precisely and easily tuned by varying the polymerization time. | |||

| While the focus of this work has been on the synthesis and characterization of macroscopic and homogeneous polymer carpets, the two-step approach can potentially be applied for the fabrication of structured, mixed, as well as gradient polymer carpets on the micrometer and nanometer scale, analogously to this work on SIPGP on crosslinked SAMs. This will further expand the variability and scope of this new class of materials. | |||

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|||

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|||